Multi-mode optimization-based sewage treatment SBR technological process control expert system

A technology of sewage treatment and expert system, which is applied in the field of environmental engineering, can solve problems such as being in the initial stage, staying in the theoretical and experimental stage, and few cases of practical application, so as to assist operation management, solve uneven distribution, and improve operation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: The following are the steps to confirm the operation mode

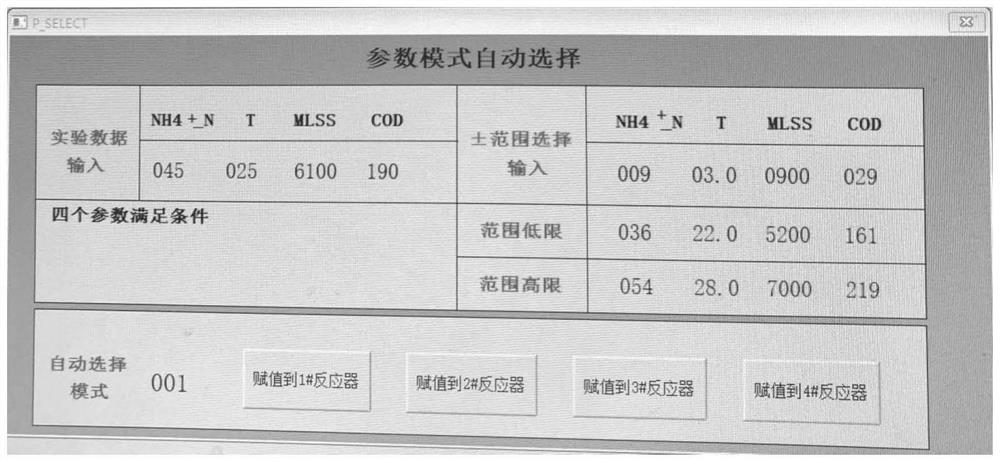

[0033] Step 1: Input the water quality parameters of the influent and the reactor environment parameters, the COD concentration is 190, the NH4+-N concentration is 50, the sludge concentration MLSS is 6100, and the seasonal temperature (T) is 20.

[0034] Step 2: The system matches the input parameters one by one with the 9 pre-stored operating modes according to the system preset parameter range deviation and parameter priority, and finally matches the most reasonable operating mode, and uses the matching results to calculate the process. The actual parameters are displayed to the operator in the same number of ways as the model parameters (e.g. image 3 shown), in order to judge the feasibility of the mode.

[0035] Step 3: If the operator analyzes the matching result and approves it, choose which reactors to assign the final operating parameters to.

[0036] If the operator analyzes the matching...

Embodiment 2

[0039] Step 1: Input the water quality parameters of the influent and the environmental parameters of the reactor, the COD concentration is 190, the NH4+-N concentration is 30, the sludge concentration MLSS is 6100, and the seasonal temperature (T) is 20.

[0040] Step 2: The system matches the input parameters one by one with the 9 pre-stored operating modes according to the system preset parameter range deviation and parameter priority, and finally matches the most reasonable operating mode, and uses the matching results to calculate the process. The actual parameters are displayed to the operator in the same number of ways as the strategy pattern parameters (such as Figure 4 shown), in order to judge the feasibility of the model.

[0041] Step 3: There is no matching pattern in the knowledge base of the expert system, and the operator selects appropriate operating parameters according to the input parameters. Select which reactors to assign the final operating parameters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com