Preparation method and application of nano-silver antibacterial liquid

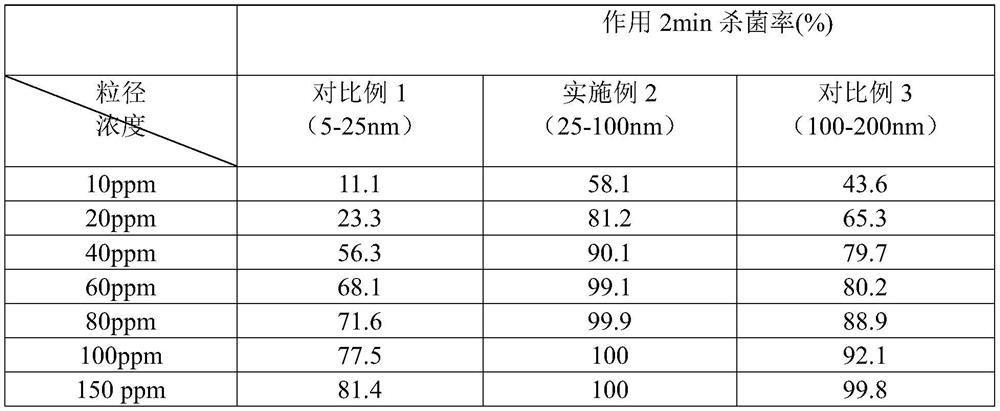

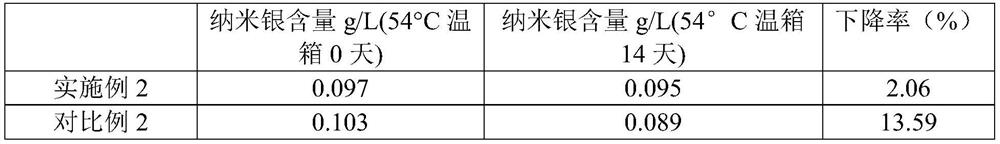

A technology of antibacterial liquid and nano-silver, which is applied in nanotechnology, nanotechnology, nano-medicine, etc., can solve the problems of nano-silver concentration decrease, complex synthesis process, and difficulty in preservation, so as to reduce water evaporation, reduce allergy risk, and good antibacterial effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

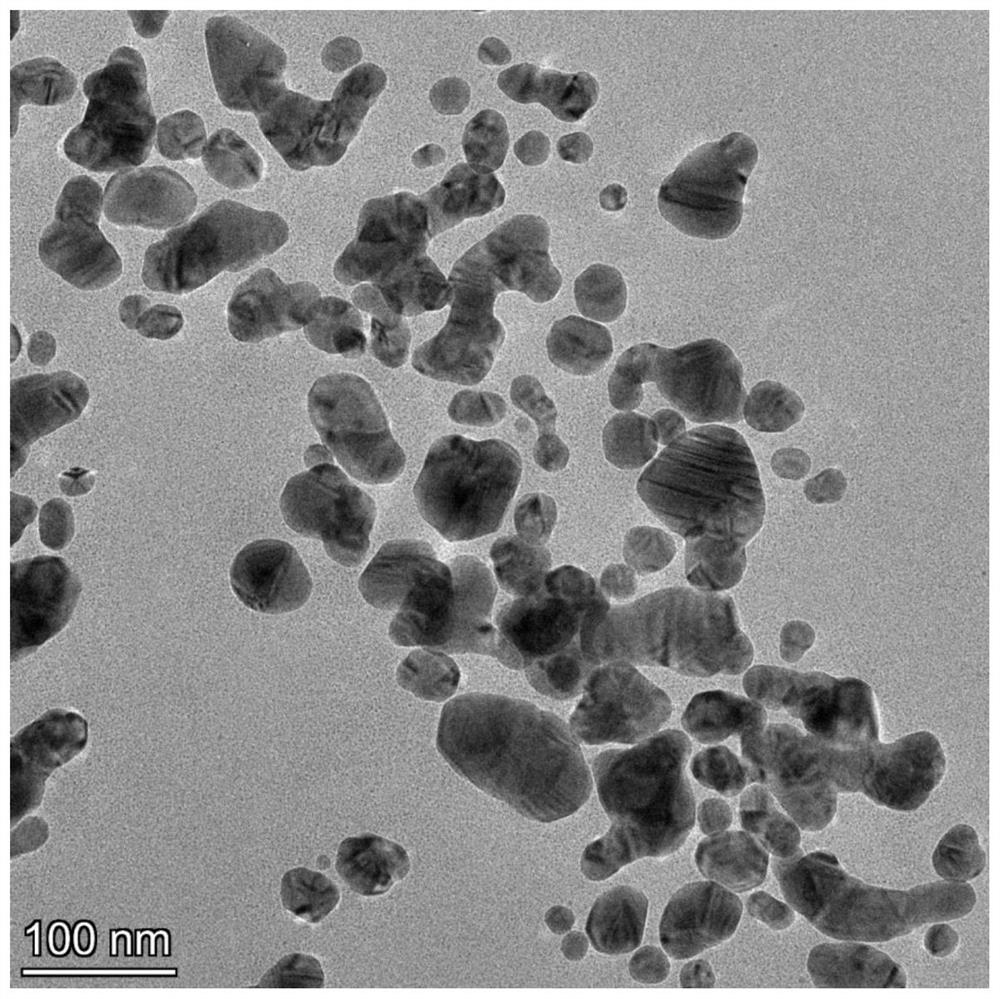

Image

Examples

Embodiment 1

[0030] Preparation of S1 raw materials:

[0031] Preparation of solution A: fully dissolve 90 g of silver nitrate in 5 kg of pure water, and then adjust the pH value to 8 with ammonium hydroxide to prepare solution A.

[0032] Prepare the same carrier solution: add 40g of propylene glycol, 50g of glycerin, 500g of pure water, 7g of poly-4-vinylpyridine into the reaction kettle and mix the mixed solution B evenly, then slowly add the graphite phase nitriding under the stirring speed of 5000rpm Carbon 25g, and added at 35min, then purified for 24h, and finally filtered to obtain the same carrier solution.

[0033] S2 high speed emulsification:

[0034] Add 300g of sodium citrate, 50g of potassium sodium tartrate, 600g of glucose, and 300kg of pure water into the high-speed stirring emulsifier, and mix evenly to obtain mixed solution C; and heat to boil under nitrogen protection to obtain boiling mixed solution C. Then rotating speed is 1500rpm under the mechanical agitation, s...

Embodiment 2

[0038] Preparation of S1 raw materials:

[0039] Preparation of solution A: fully dissolve 100 g of silver nitrate in 5 kg of pure water, and then adjust the pH value to 7 with ammonium hydroxide to prepare solution A.

[0040]Prepare the same carrier solution: add 50g of glycerol, 30g of butanediol, 500g of pure water, 10g of poly-4-vinylpyridine into the reaction kettle and mix the mixed solution B evenly, then slowly add the graphite phase under stirring at a speed of 4000rpm Add 40g of carbon nitride, and finish adding in 40min, then purify for 24h, and finally filter to obtain the same carrier solution.

[0041] S2 high speed emulsification:

[0042] Add 200g of pentasodium diethylenetriaminepentaacetic acid, 100g of potassium sodium tartrate, 600g of ascorbic acid, and 300kg of pure water into the high-speed stirring emulsifier, and mix well to obtain a mixed solution C; and heat it to boil under the protection of nitrogen to obtain a boiling mixed solution c. Then ro...

Embodiment 3

[0046] Preparation of S1 raw materials:

[0047] Preparation of solution A: fully dissolve 110 g of silver nitrate in 5 kg of pure water, and then adjust the pH value to 8 with ammonium hydroxide to prepare solution A.

[0048] Preparation of the same carrier solution: Add 80g of propylene glycol, 12g of glycerin, 500g of pure water, 8g of poly-4-vinylpyridine into the reaction kettle and mix the mixed solution B evenly, then slowly add the graphite phase nitriding under the stirring speed of 4000rpm 45g of carbon was added at 40 minutes, then purified for 24 hours, and finally filtered to obtain the same carrier solution.

[0049] S2 high speed emulsification:

[0050] Add 50g of sodium citrate, 280g of pentasodium diethylenetriaminepentaacetic acid, 300g of glucose, 400g of ascorbic acid, and 300kg of pure water into the high-speed stirring emulsifier, and mix well to obtain a mixed solution C; The mixed solution C. Then rotating speed is 2000rpm under mechanical stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com