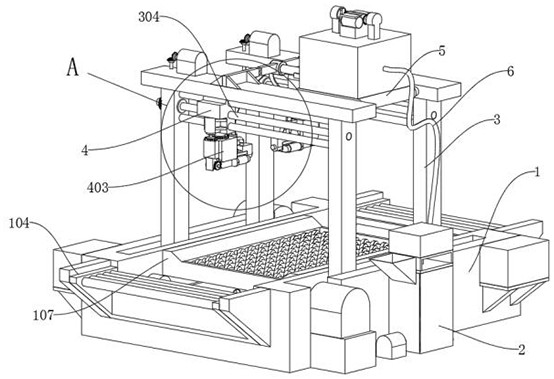

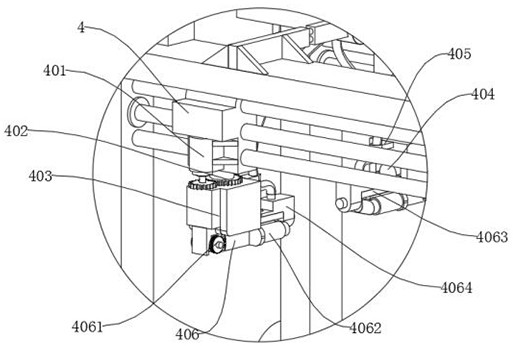

Anti-blocking clarifying agent spraying device for glass manufacturing

A technology of glass manufacturing and spraying devices, applied in spraying devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of glass spraying operation rate reduction, glass damage, clogging, etc., achieve uniform and comprehensive spraying operations, improve adaptability, prevent The effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0042] Embodiment two, such as Figure 9 As shown, other structures remain unchanged, and a bearing structure can be added. The bearing structure includes: a collection carrier frame 108, the collection carrier frame 108 is arranged on the inside of the spray carrier 1, and a dredging carrier plate 1081, and the dredging carrier plate 1081 is arranged on the collection carrier frame 108 Inner side, delivery carrier 1082, delivery carrier 1082 is offered at the top of dredging carrier 1081, discharge carrier 1083, discharge carrier 1083 is arranged on one side of injection carrier 1, and discharge carrier 1083 communicates with delivery carrier 1082; When spraying, the collecting carrier frame 108 cooperates with the dredging carrier plate 1081, which can accept and store the excess clarifier that flows down after spraying, thereby preventing the excess clarifier from flowing around and causing unnecessary pollution to the surroundings, and ensuring the cleanliness of the entire...

Embodiment 3

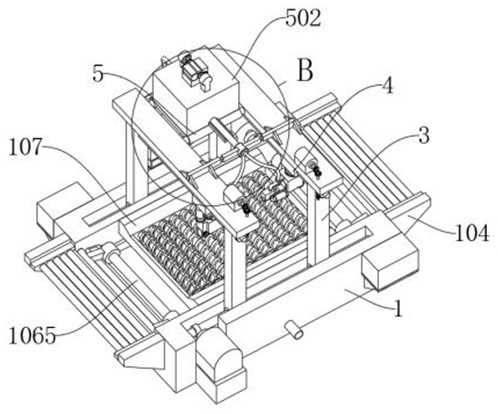

[0043] Embodiment three, such as Figure 14As shown, other structures remain unchanged, and a pressurization structure can be added. The pressurization structure includes: a driving sled 506, which is arranged on the top of the movable storage box 502, and a delivery press plate 5061, which is arranged on the drive swipe 506 The end moves on the inside of the storage case 502 at the same time, drives the slot 5062, and the drive slot 5062 is opened on the other end of the drive spool 506, and the mounting seat 5063 is installed on the top of the storage case 502, and the reciprocating motor 5064, The reciprocating motor 5064 is installed on both sides of the mounting base 5063, the reciprocating rotating shaft 5065, and the reciprocating rotating shaft 5065 is rotated and arranged on the inside of the mounting base 5063, and the reciprocating rotating part 5066 is arranged on both ends of the reciprocating rotating shaft 5065; driven by the reciprocating motor 5064 The recipro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com