High power tunable CO2 laser

A carbon dioxide and laser technology, applied in the field of lasers, can solve problems such as inconvenience in laser design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

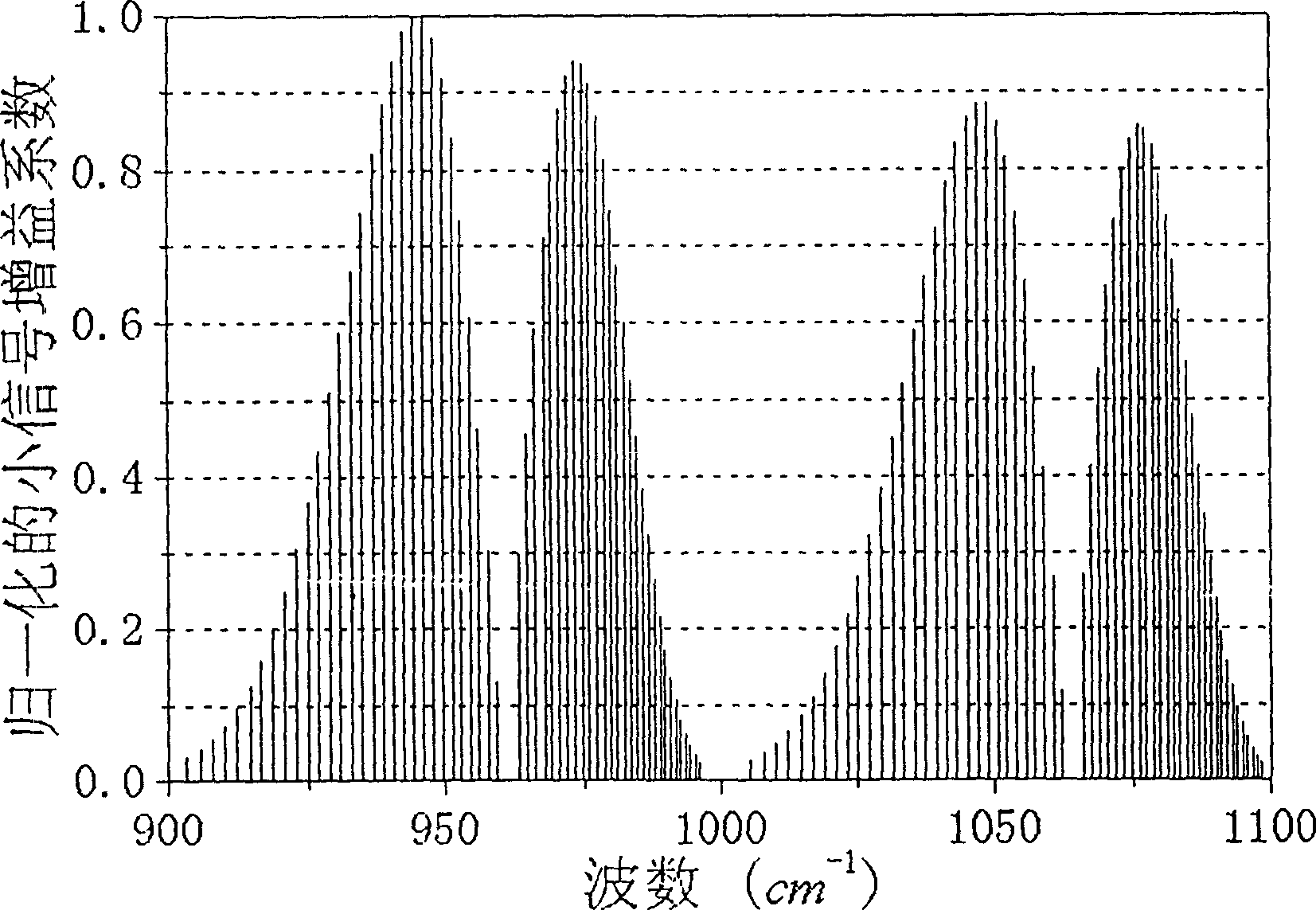

[0017] Please see first image 3 The normalized CO 2 Distribution of laser transition small-signal gain with frequency. CO 2 There can be about 100 laser transition lines in the wavelength range of 9 to 11 μm, which belong to four transition bands of 10P, 10R, 9P, and 9R (00°1-10°0 band and 00°1-02°0 band of P branch and R branch). It can be seen from the figure that the peak spectra of the four transition bands are 10P(20), 10R(18), 9P(20) and 9R(18), respectively. But a freely oscillating TEA CO without any dispersive element inside the cavity 2 In the laser, due to the result of gain competition, the laser output power is always concentrated on a spectral line with the highest gain. The 10P(20) transition line has the highest gain, so the freely oscillating TEA CO 2 The laser transition line output by the laser is 10P(20), and the laser frequency is 945cm -1 , with a wavelength of 10.6 μm.

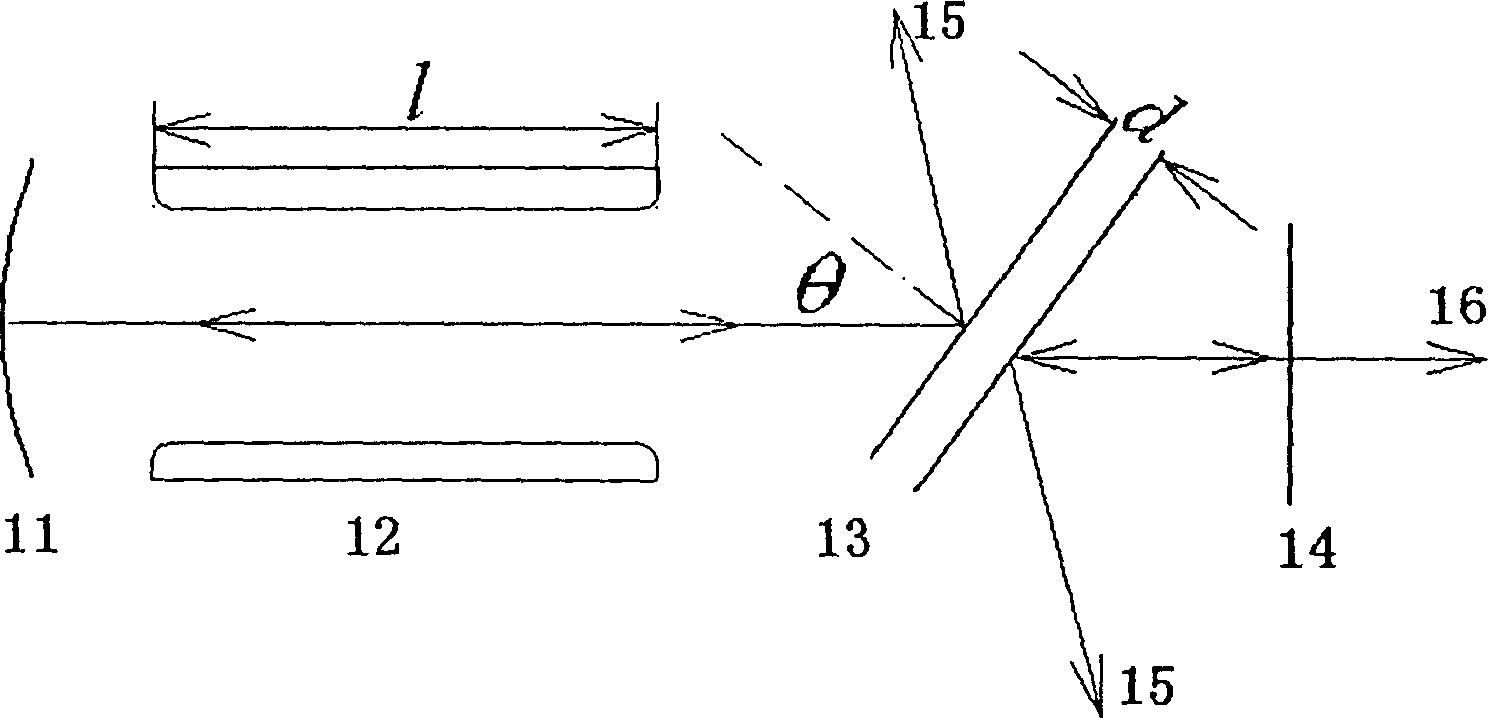

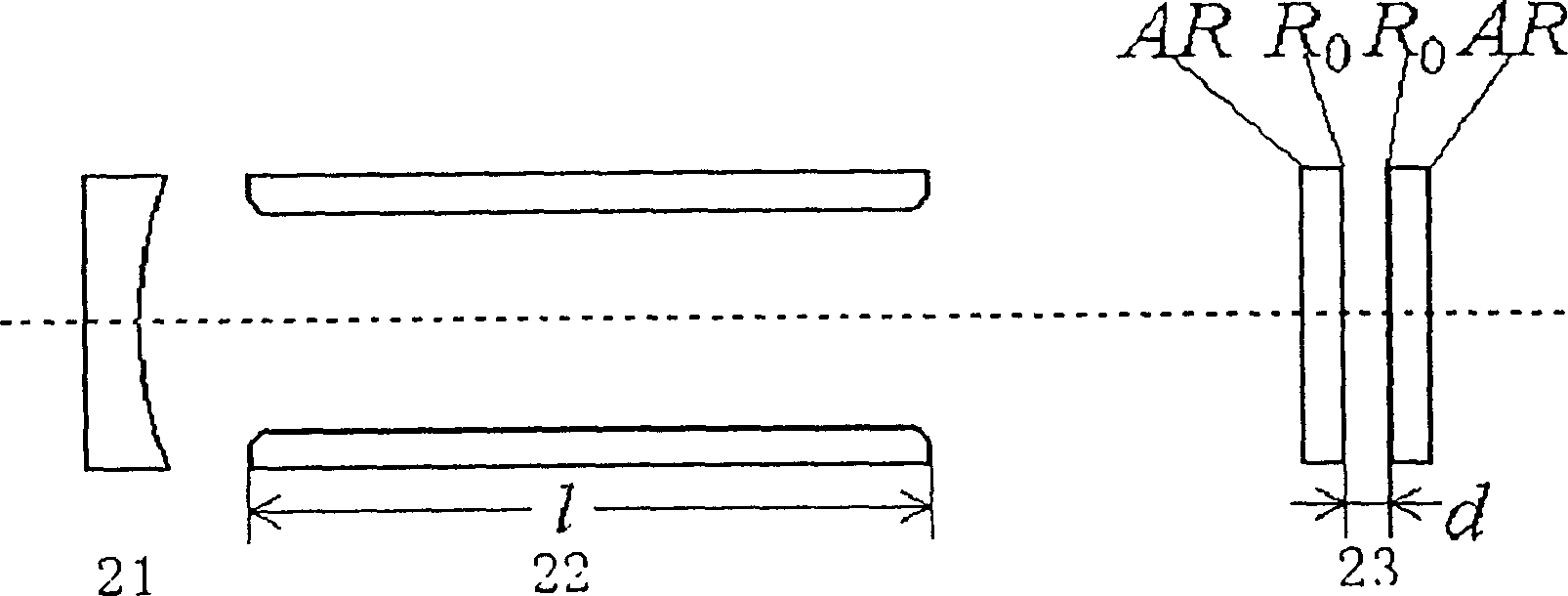

[0018] In order to obtain the output of laser transition lines in other tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com