Flexible wheel virtual assembly detection device

A technology of flexible wheels and inspection tools, applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of high maintenance cost, deformation, large investment, etc., and achieve the effect of short detection time and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

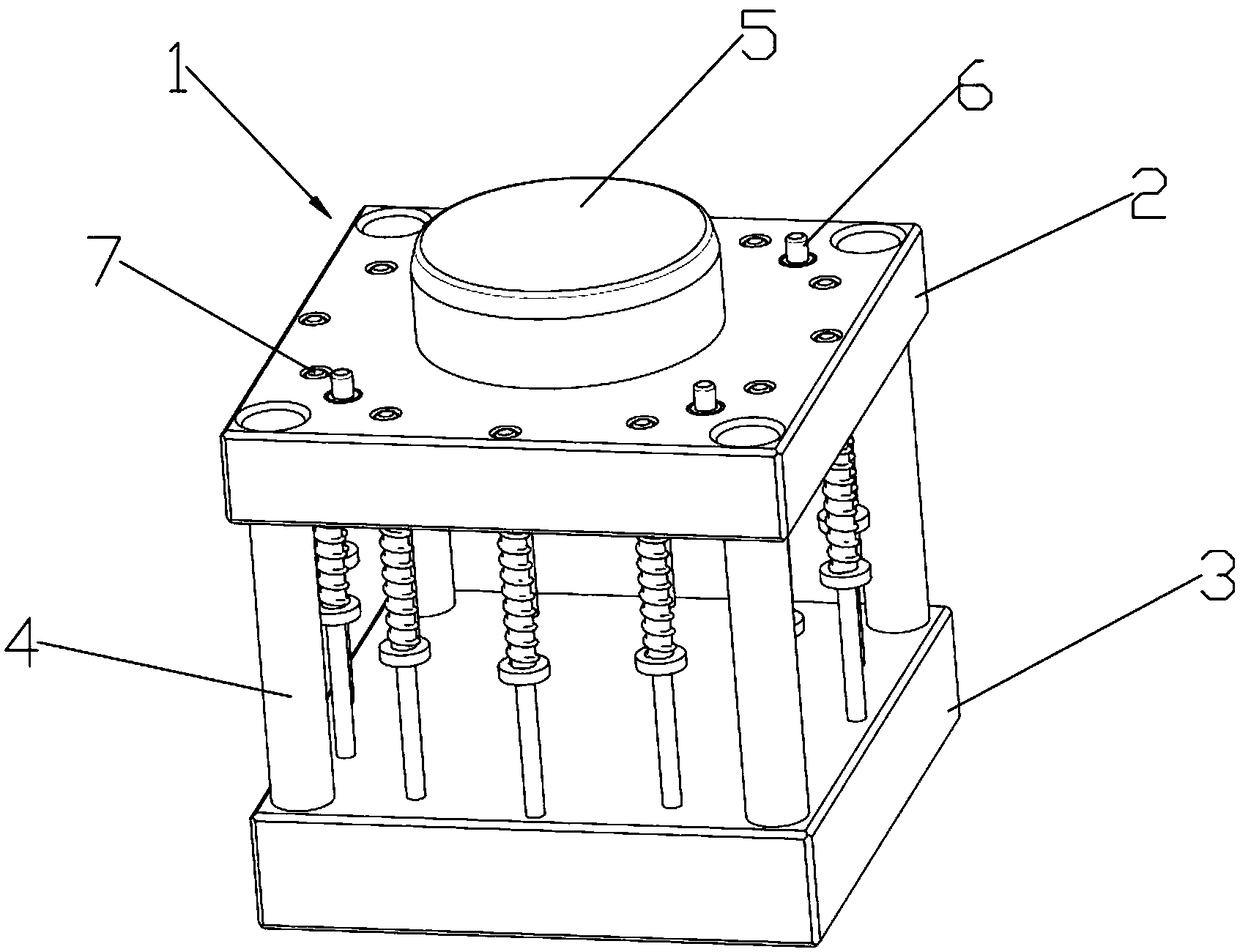

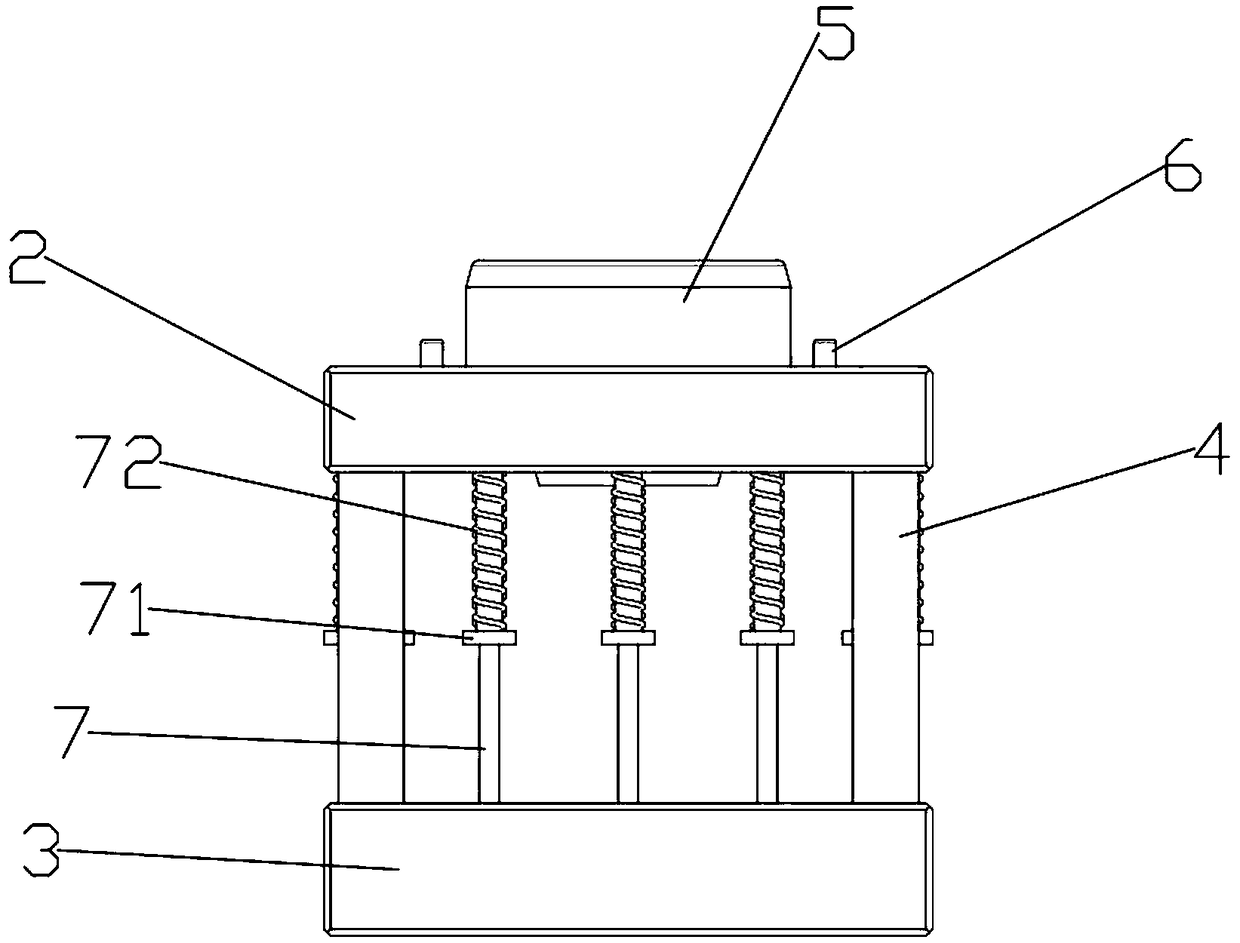

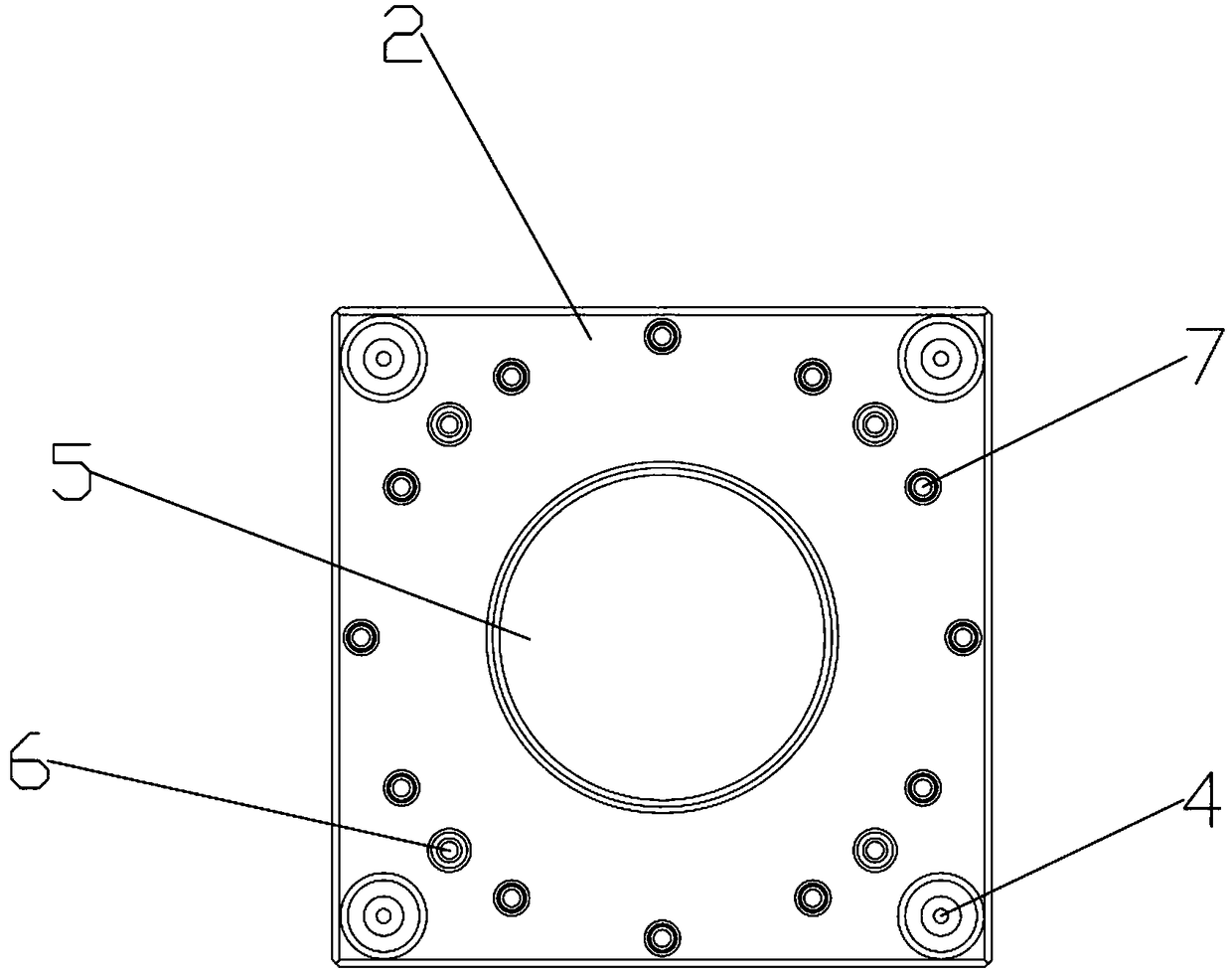

[0017] see figure 1 and image 3 As shown, the flexible spline assembly inspection tool of the present invention is used to detect the position of the flexible spline installation hole, including a measuring body 1, which is a hollow structure, and the measuring body 1 includes an upper template 2, a lower template 3, four Guide post 4, center pin 5, four positioning pins 6 and twelve bolts 7, four guide posts 4 are arranged equidistantly on the lower formwork 3 and distributed at four corners of the lower formwork 3, and the upper formwork 2 is fixed on One end of the guide column 4, the upper formwork 2 and the lower formwork 3 are facing each other, and twelve bolts 7 are movably arranged equidistantly on the lower formwork 3 and surro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com