Ophthalmic lenses for reducing myopic progression and methods of making the same

An ophthalmic lens, lens technology, applied in the direction of glasses/protective glasses, glasses/goggles, applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

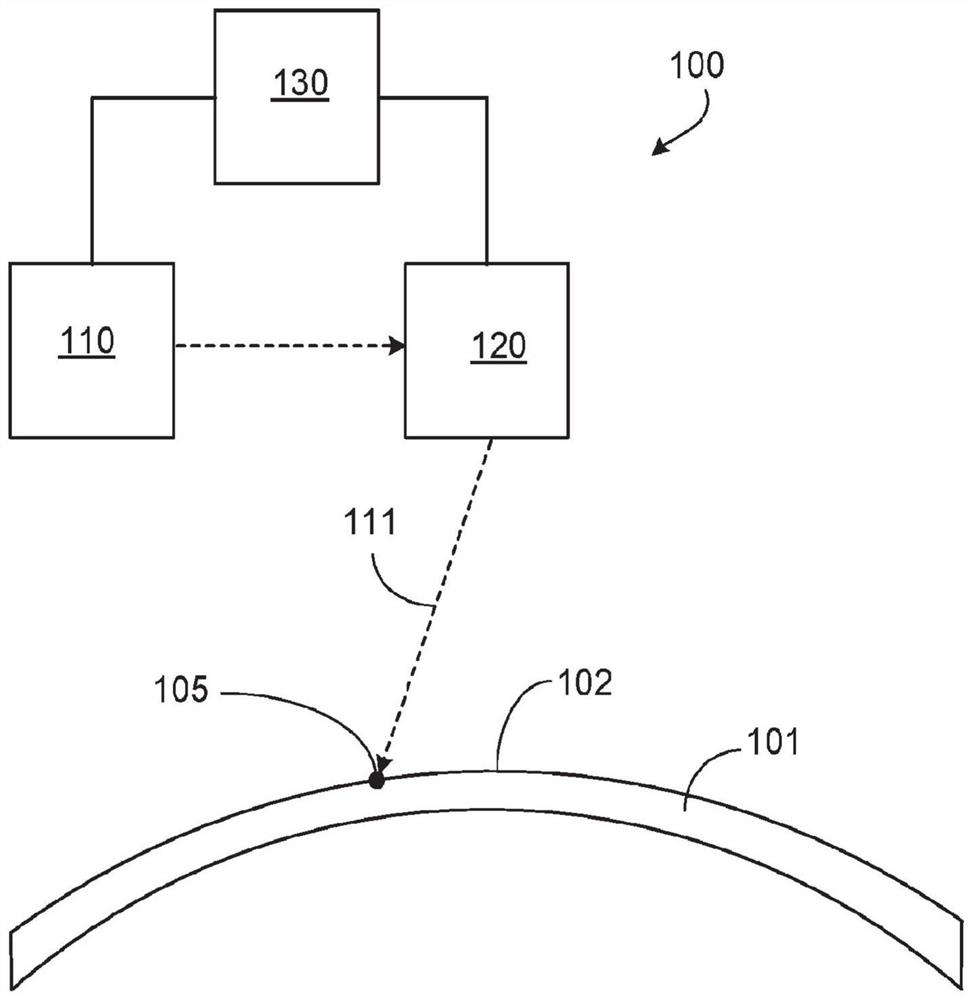

[0049] refer to figure 1 , a laser system 100 for forming optical elements 105 on a surface 102 of a conventional ophthalmic lens 101 includes a laser 110 and a beam directing assembly 120 each in communication with a controller 130 (eg, a computer controller). Laser 110 directs the laser beam towards a beam directing assembly that directs and focuses beam 111 towards optic 101 , which is positioned relative to assembly 120 by a stage (not shown). For example, beam directing assembly 120 may include actuated mirrors and one or more optics to vary the direction and focus of laser radiation. Controller 130 coordinates the operation of laser 110 and beam directing assembly 120 to expose surface 102 to pulses of laser radiation at discrete locations on the lens to form optical elements in a predetermined pattern on the lens surface.

[0050] In some implementations, the gantry also includes an actuator. The stage actuator may be a multi-axis actuator, for example, moving the mir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com