Electrolyte containing composite additive and application thereof

A technology of composite additives and electrolytes, applied in electrolytes, circuits, electrical components, etc., can solve the problems of easy flatulence of batteries and the influence of cycle performance of lithium-ion batteries on protective films, etc., achieve fast conduction rate and improve charge-discharge cycle performance , the effect of low impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In an argon glove box where the oxygen pressure and water pressure are both less than 0.1ppm, the standard electrolyte preparation composition is as follows, lithium salt: 1.0mol L -1 Lithium hexafluorophosphate; Organic solvent: a mixture of ethylene carbonate and dimethyl carbonate with a volume ratio of 3:7, as a control group;

[0034] On the basis of the reference electrolyte, composite additives were added: 2wt% lithium trifluoromethanesulfonate and 0.5wt% lithium nitrate, and the obtained electrolyte was used as the experimental group;

[0035] Heat and stir at 40°C in an argon glove box for 0.5h until lithium nitrate is completely dissolved;

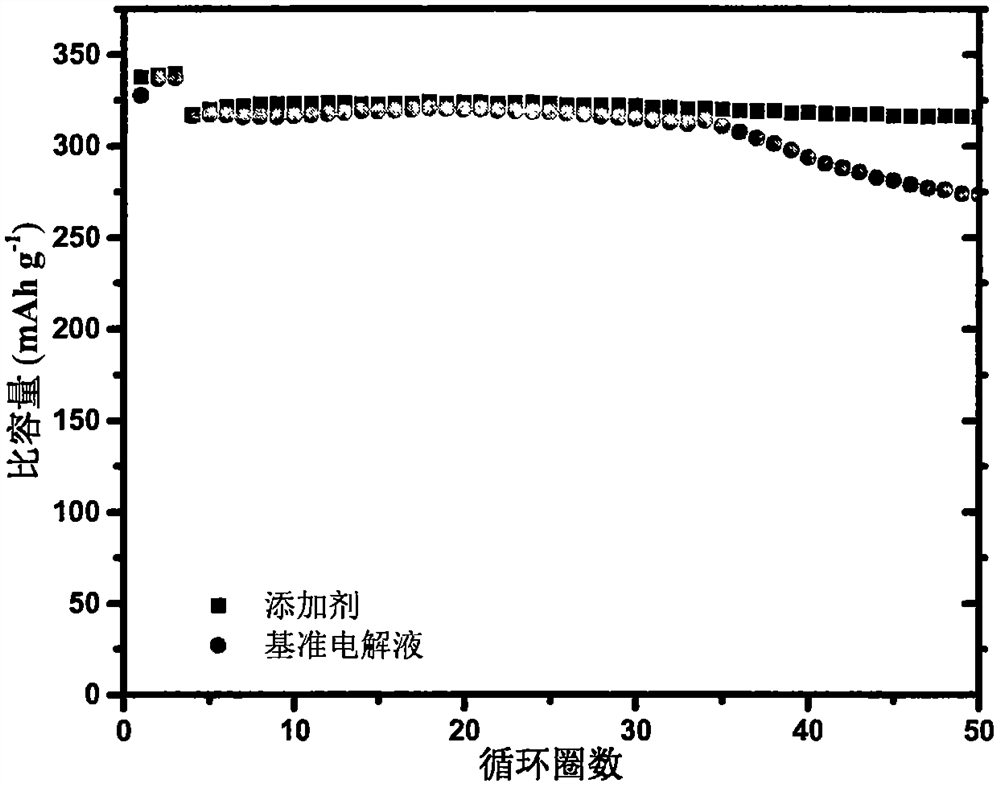

[0036] The electrolyte is used to prepare a lithium battery with artificial graphite as a negative electrode, a lithium sheet as a counter electrode, and a single-layer polypropylene film as a diaphragm. After testing, it is measured by a Li / Graphite battery and activated at 0.1C (1C=320mAh / g) After three cycles, the capa...

Embodiment 2

[0038] In an argon glove box where the oxygen pressure and water pressure are both less than 0.1ppm, the standard electrolyte preparation composition is lithium salt; 1.0mol L -1 Lithium hexafluorophosphate; organic solvent: a mixture of ethylene carbonate and dimethyl carbonate in a volume ratio of 3:7, as a control group;

[0039] On the basis of the reference electrolyte, composite additives: 3wt% lithium tetrafluoroborate and 0.5wt% lithium nitrate were added, and the obtained electrolyte was used as the experimental group;

[0040] Heat and stir at 40° C. for 0.5 h in an argon glove box until lithium nitrate is completely dissolved.

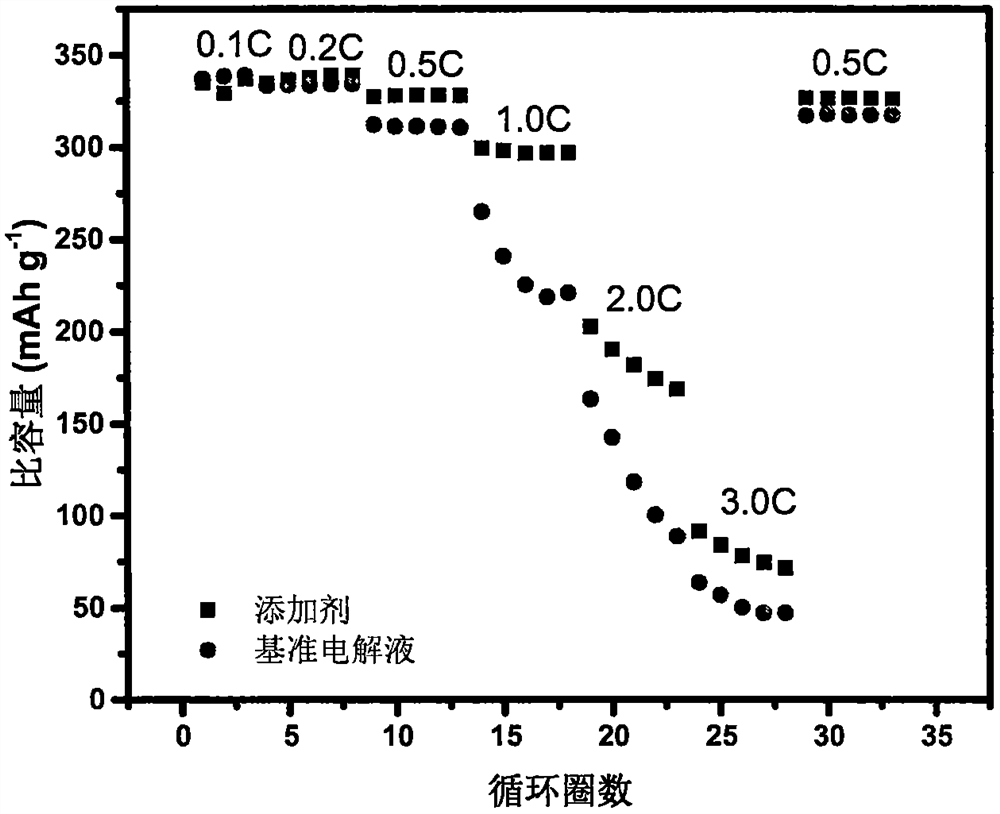

[0041] The electrolyte is used for the full battery test with metal lithium as the negative electrode and nickel-cobalt lithium manganese oxide as the positive electrode. The single-layer polypropylene film is used as the separator. After testing, after three cycles of activation at 0.1C (1C=220mAh / g), the experimental group The capacities ...

Embodiment 3

[0043] In an argon glove box with oxygen pressure and water pressure less than 0.1ppm, the electrolyte preparation composition is as follows: lithium salt: 1.0mol L-1 lithium hexafluorophosphate; organic solvent: ethylene carbonate: dimethyl carbonate = 3: 7 ( volume ratio); composite additives: 1wt% lithium trifluoroacetate and 1wt% lithium nitrate, heated and stirred at 40° C. for 0.5 h in an argon glove box until the lithium nitrate was completely dissolved.

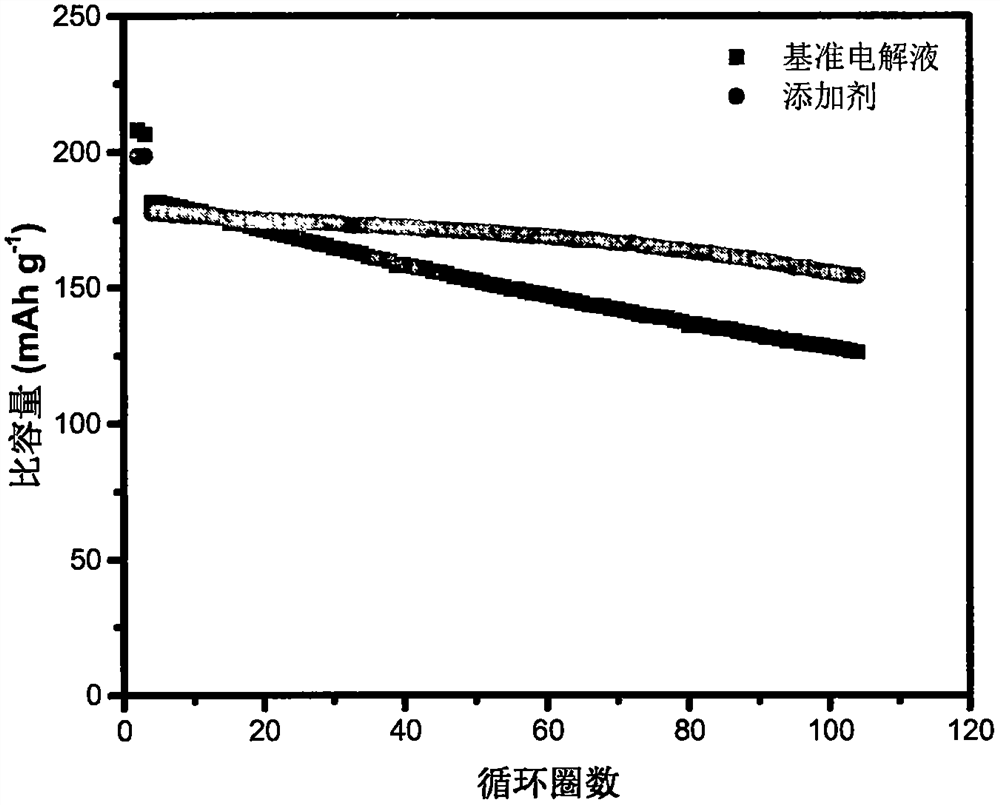

[0044] The electrolyte is used for full battery testing with metal lithium as the negative electrode and nickel-cobalt lithium manganese oxide as the positive electrode. The single-layer polypropylene film is used as the diaphragm. After testing, the capacity after three cycles of activation at 0.1C (1C=200mAh / g) is 208.5 mAh / g, the capacity after 100 cycles at 1.0C is 153.7mAh / g, and the capacity retention rate is 73.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com