Three-dimensional impeller variable-axis plunge milling semi-finishing cutter location planning method

A ternary impeller and semi-finishing technology, applied in the direction of electrical program control, digital control, etc., can solve the problems of low processing efficiency, empty knife, etc., and achieve the effect of improving processing efficiency, improving processing technology, and effective cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that those skilled in the art can make several changes and improvements without departing from the concept of the present invention. These all belong to protection domain of the present invention.

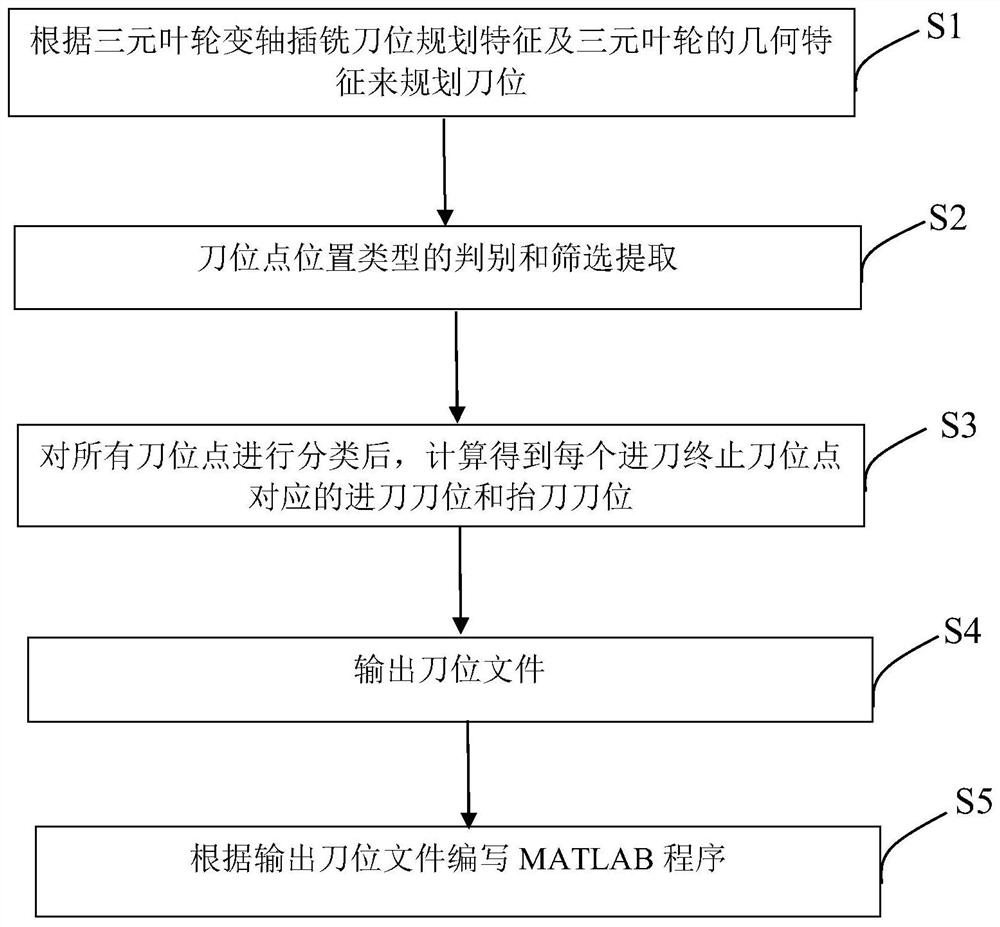

[0038] Specifically, such as figure 1 As shown, the present invention provides a tool position planning method for semi-finishing machining of ternary impeller variable shaft plunge milling, said method comprising the following steps:

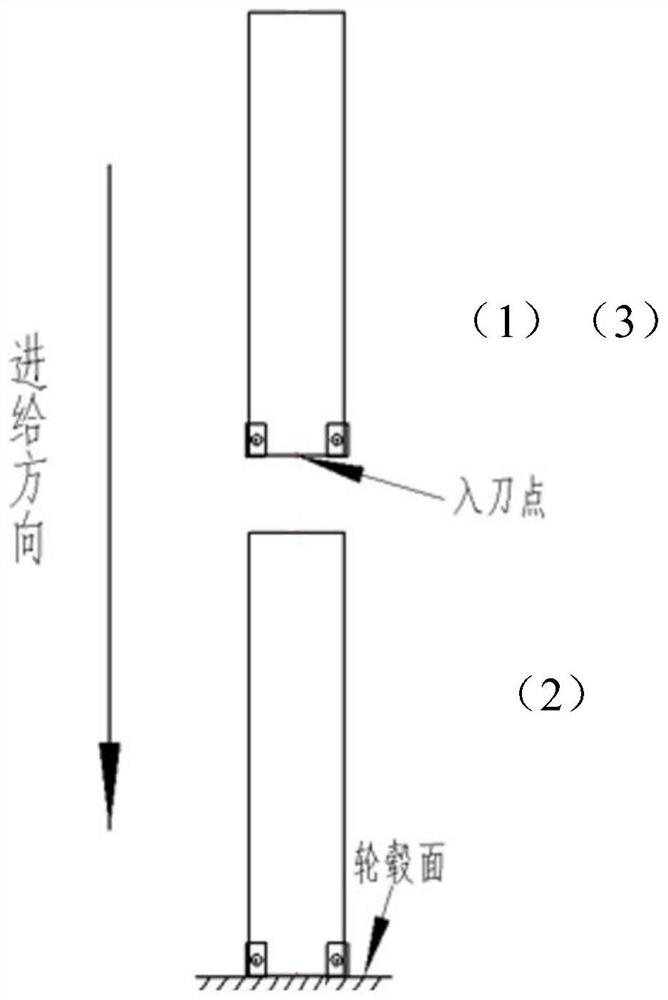

[0039] S1: Plan the cutter position according to the planning characteristics of the three-dimensional impeller variable axis plunge milling tool position and the geometric characteristics of the three-dimensional impeller;

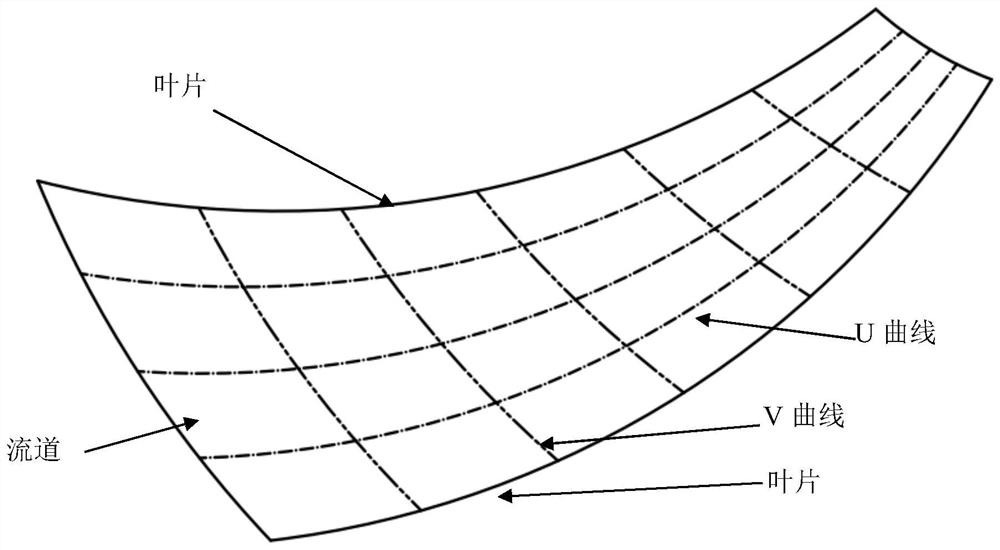

[0040] Specifically, such as figure 2 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com