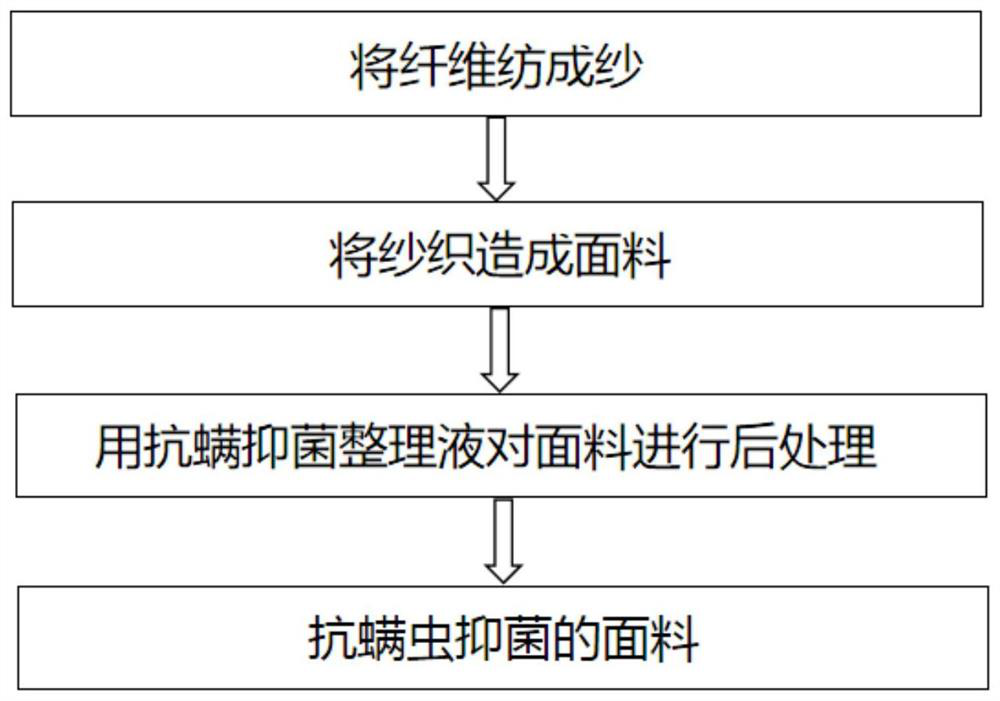

Preparation process of anti-mite and antibacterial fabric

A preparation process and fabric technology, applied in the field of textile fabrics, can solve the problems that it is difficult to fully penetrate the fabric with finishing liquid, the treatment effect is not good, and the impregnation time is increased, so as to inhibit the growth and reproduction of bacteria and mites, and have good skin affinity , Improve the effect of anti-mite and antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Preparation of anti-mite antibacterial fabric:

[0067] (1) Take the cotton fiber and spin it into yarn through opening, blending, carding, drawing, twisting and drafting;

[0068] The count of the spun yarn is 40;

[0069] (2) Weaving yarn into fabric;

[0070] The density of the woven fabric is 140 warp yarns and 110 weft yarns per square inch;

[0071] (3) Perform anti-mite and antibacterial post-treatment on the fabric:

[0072] 1) Preparation of anti-mite and antibacterial finishing solution:

[0073] a) Take 5 parts of carboxymethyl chitosan, 3 parts of matrine, 1 part of 2-methyl-4-isothiazolin-3-one, 100 parts of pure water, 0.1 part of emulsifier AEO-7, silane Joint agent KH550 0.1 part, sodium alginate 0.05 part;

[0074] b) Sodium alginate and carboxymethyl chitosan are added to pure water, and stirred to a transparent and viscous solution, the viscosity of the solution is 300mPa·s;

[0075] c) adding matrine to the above transparent and viscous solutio...

Embodiment 2

[0082] Preparation of anti-mite antibacterial fabric:

[0083] (1) Take cotton fiber and vinylon, cotton fiber and vinylon are opened and mixed to form mixed fibers, and the mixed fibers are spun into yarn through carding, drawing, twisting and drafting;

[0084] In the mixed fiber formed by cotton fiber and vinylon, 50 parts of cotton fiber and 50 parts of vinylon;

[0085] The count of the spun yarn is 40;

[0086] (2) Weaving yarn into fabric;

[0087] The density of the woven fabric is 140 warp yarns and 110 weft yarns per square inch;

[0088] (3) Perform anti-mite and antibacterial post-treatment on the fabric:

[0089] The anti-mite antibacterial finishing solution and the post-treatment steps of anti-mite antibacterial are the same as in Example 1.

Embodiment 3

[0091] Preparation of anti-mite antibacterial fabric:

[0092] (1) get cotton fiber and bamboo pulp fiber, cotton fiber and bamboo pulp fiber are formed mixed fiber through cotton opening, blending, and mixed fiber is spun into yarn through carding, drawing, twisting and drafting;

[0093] In the mixed fiber formed by cotton fiber and bamboo pulp fiber, 50 parts of cotton fiber and 50 parts of bamboo pulp fiber;

[0094] The count of the spun yarn is 40;

[0095] (2) Weaving yarn into fabric;

[0096] The density of the woven fabric is 140 warp yarns and 110 weft yarns per square inch;

[0097] (3) Perform anti-mite and antibacterial post-treatment on the fabric:

[0098] The anti-mite antibacterial finishing solution and the post-treatment steps of anti-mite antibacterial are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com