Large workpiece positioning and clamping system and method

A technology for positioning and clamping, large workpieces, applied in positioning devices, metal processing machinery parts, clamping, etc., can solve problems such as unrestricted excess degrees of freedom of workpieces, defective products with out-of-tolerance dimensions, and easy displacement of workpieces, etc., to achieve clamping Good holding effect, avoiding the interference of machining accuracy, and eliminating the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

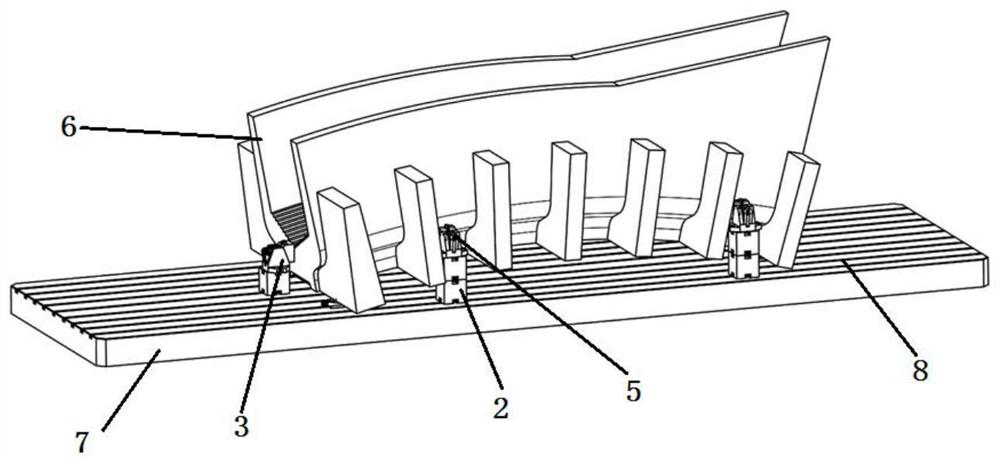

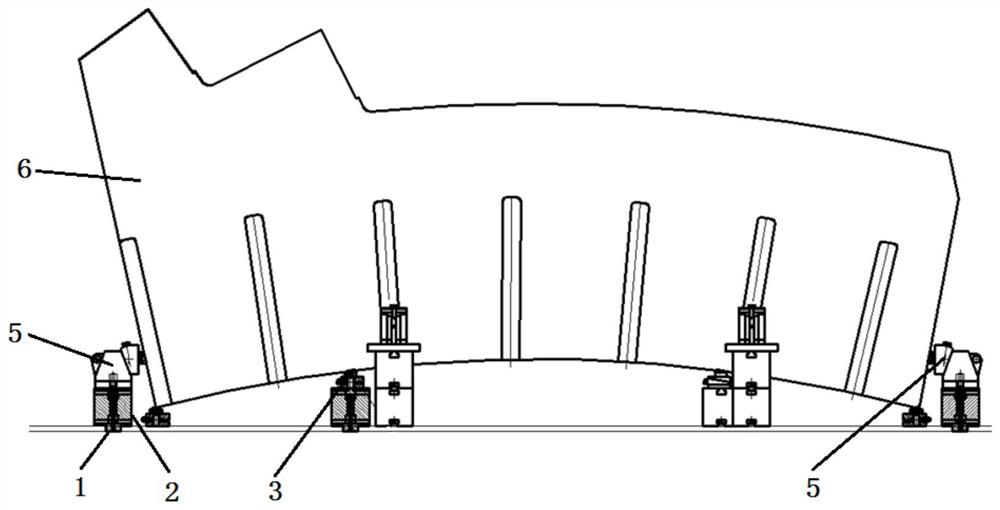

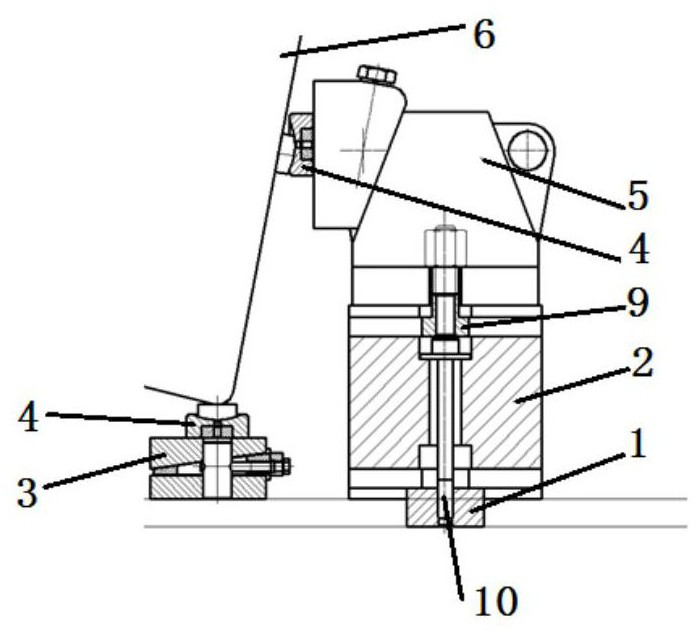

[0041] Such as Figure 1~3 A large workpiece positioning and clamping system shown includes a clamping platform 7, several adjustable parallel iron structures 3, several free vises 5 and spherical washers 4, and the adjustable parallel iron structures 3 are used for supporting and leveling The workpiece 6 is distributed around the workpiece 6 at circumferential intervals; a spherical washer 4 is installed on the top of the adjustable parallel iron structure 3, and the bottom of the adjustable parallel iron structure 3 is directly installed on the clamping platform 7, or by supporting The structure is installed on the clamping platform 7; the free vise 5 is used to apply pressure to the outer surface of the workpiece 6 to straighten the workpiece 6, and the free vise 5 is distributed around th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com