Method for controlling leakage of membrane source disinfection by-product precursor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

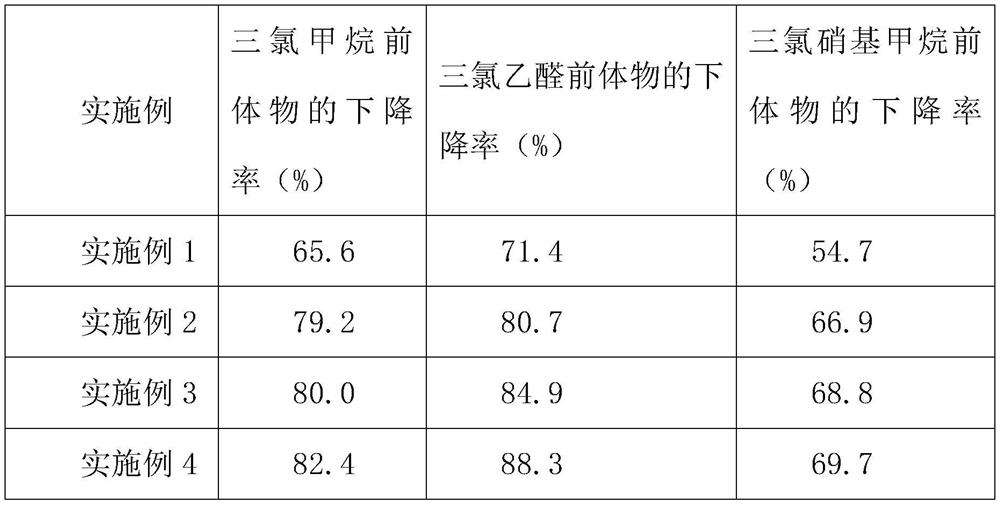

Examples

Embodiment 1

[0039] The method of pretreatment of ultrafiltration membrane to control membrane source disinfection by-product precursor with the aqueous solution containing sodium hypochlorite of the present embodiment comprises the steps:

[0040]Use a phosphate buffer solution to adjust the pH value of the sodium hypochlorite solution containing an initial concentration of 3mg / L to 7.0, and then use the above sodium hypochlorite solution to filter the treatment unit through the ultrafiltration membrane to pre-filter the new ultrafiltration membrane. The pretreatment time for 1 hour, and then rinse with ultrapure water until the concentration of residual chlorine in the effluent is lower than 0.01mg / L. The material of the ultrafiltration membrane used is polyethersulfone, the molecular mass cut-off is 5000Da, and the operating pressure of the ultrafiltration treatment unit is 0.35Mpa. After the pretreatment is completed, the actual water body passes through the ultrafiltration membrane fil...

Embodiment 2

[0042] The method of pretreatment of ultrafiltration membrane to control membrane source disinfection by-product precursor with the aqueous solution containing sodium hypochlorite of the present embodiment comprises the steps:

[0043] Use phosphate buffer solution to adjust the pH value of the sodium hypochlorite solution containing an initial concentration of 4mg / L to 7.5, then use the above-mentioned sodium hypochlorite solution to pass through the ultrafiltration membrane filtration treatment unit to carry out pre-filtration treatment on the new ultrafiltration membrane, pretreatment time for 2 hours, and then rinse with ultrapure water until the concentration of residual chlorine in the effluent is lower than 0.01mg / L. The material of the ultrafiltration membrane used is polyvinylidene fluoride, the molecular mass cut-off is 50000Da, and the operating pressure of the ultrafiltration treatment unit is 0.3Mpa. After the pretreatment is completed, the actual water body passes...

Embodiment 3

[0045] The method of pretreatment of ultrafiltration membrane to control membrane source disinfection by-product precursor with the aqueous solution containing sodium hypochlorite of the present embodiment comprises the steps:

[0046] Use phosphate buffer solution to adjust the pH value of the sodium hypochlorite solution containing an initial concentration of 5mg / L to 7.0, then use the above sodium hypochlorite solution to filter the treatment unit through the ultrafiltration membrane to pre-filter the new ultrafiltration membrane, pretreatment time for 1 hour, and then rinse with ultrapure water until the concentration of residual chlorine in the effluent is lower than 0.01mg / L. The material of the ultrafiltration membrane used is polyvinylidene fluoride, the molecular mass cut-off is 10000Da, and the operating pressure of the ultrafiltration treatment unit is 0.3Mpa. After the pretreatment is completed, the actual water body passes through the ultrafiltration membrane filtr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com