Intelligent wet-type dust removal equipment

A wet dust removal and intelligent technology, applied in the direction of dispersed particle separation, chemical instruments and methods, and the use of liquid separation agents, can solve problems such as easy blockage of horizontal pipes, secondary pollution of dust collectors, and failure to achieve dust control, and achieve the goal of capturing It has strong self-cleaning ability, wide range of dust concentration and satisfactory purification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

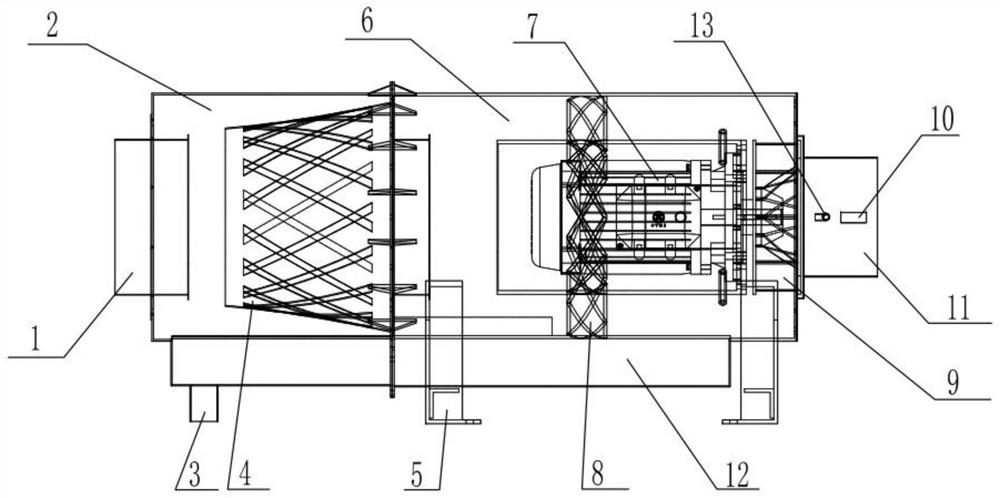

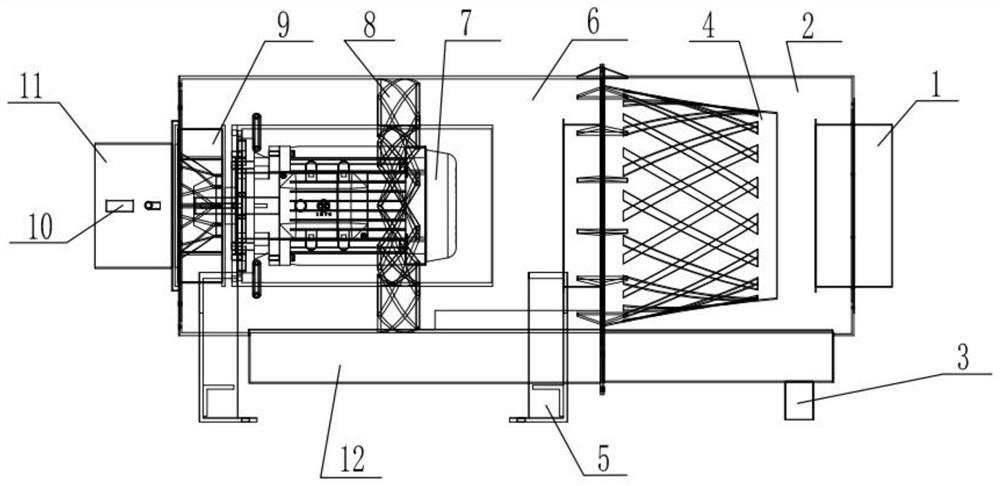

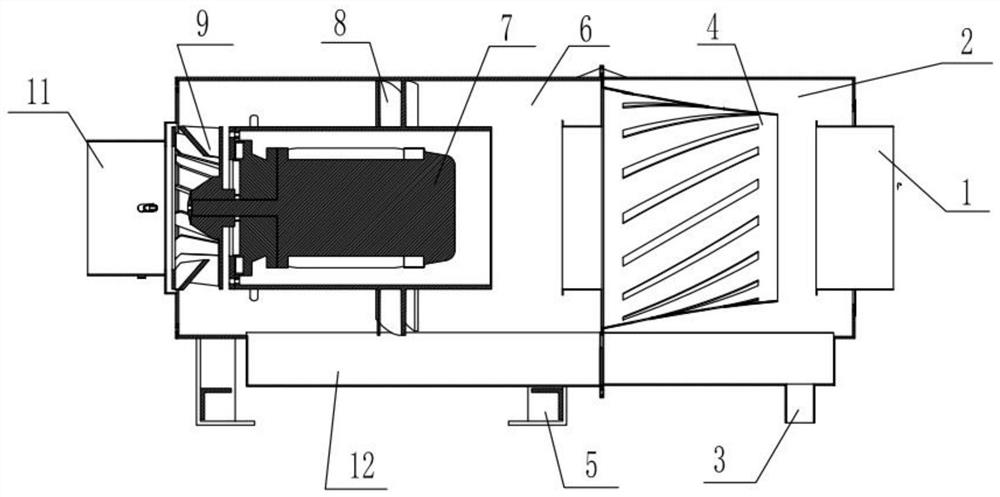

[0040] According to the real-time data of on-site dust particle content, the fan parameters are adjusted at the near end; the operating parameters of the dust removal fan are controlled by manually inputting the interval value of the dust content and the frequency of the driving device 7 . Under the high-speed rotation of the fan impeller 9, the resulting negative pressure sucks the dust-laden air into the fan through the air inlet 11. The dust detection module 10 detects the particle content of the air inlet 11 in the current environment. The dust-laden air flows first before passing through the fan impeller 9. When spraying the spray system 13, it is mixed with the water mist ejected from the atomizing nozzle 13-1 and then enters the fan, and the dust-laden air flow and the water mist are further mixed when they pass through the fan under the agitation of the fan impeller 9, so as to strengthen the water mist and the air flow. The interaction of dust, the dust-laden air flow ...

Embodiment 2

[0043] According to the real-time data of on-site dust particle content, the fan parameters are adjusted at the near end. After the interval value is manually input at the near end, the drive device will self-adjust according to the dust concentration detected at the front end, and the settings will be made during installation, and the drive will be automatically adjusted during subsequent use. The speed of the device, or the interval value can be set remotely, and at the same time, the motor temperature, current, particle content at the inlet and outlet, purification efficiency, and water flow data are displayed digitally on the display screen of the monitoring center. Under the high-speed rotation of the fan impeller 9, the resulting negative pressure sucks the dust-laden air into the fan through the air inlet 11. The dust detection module 10 detects the particle content of the air inlet 11 in the current environment. The dust-laden air flows first before passing through the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com