False tooth repairing method and equipment

A restoration method and denture technology, applied in the field of orthodontics, can solve problems such as cumbersome process, labor-intensive, and low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

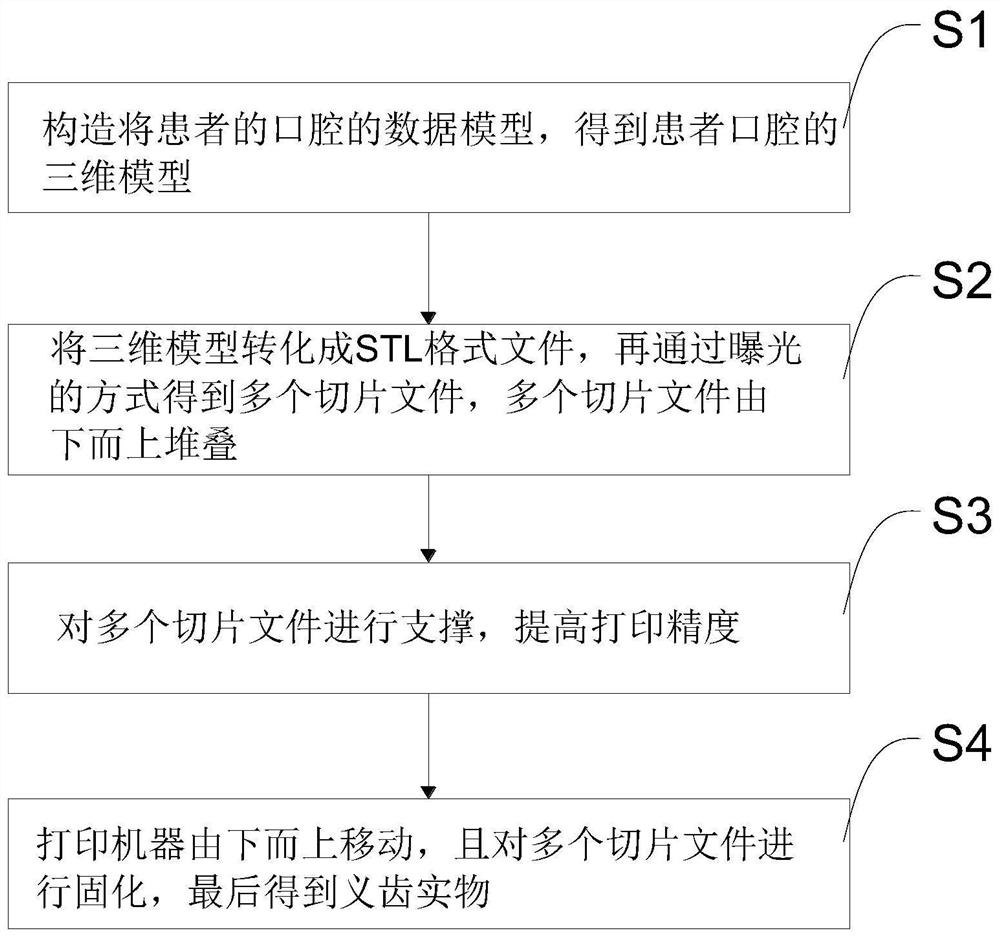

[0030] Please refer to figure 1 shown. A denture repair method provided in the embodiment of the present application includes the following steps: S1: Construct a data model of the patient's oral cavity to obtain a three-dimensional model of the patient's oral cavity; S2: Convert the three-dimensional model into an STL format file, and then through the exposure method Multiple slice files are obtained, and multiple slice files are stacked from bottom to top; S3: Support multiple slice files to improve printing accuracy; S4: The printing machine moves from bottom to top, and solidifies multiple slice files, and finally Get real dentures.

[0031]In the above embodiment, a denture repair method can be specifically divided into three major steps: data processing, molding process and post-processing. Among them, data processing: before performing photo-curing printing, it is necessary to obtain slice files of each layer, and the acquisition of slice files requires The following ...

Embodiment 2

[0049] A computer-readable storage medium is used for storing program codes, and the program codes are used for executing the method.

Embodiment 3

[0051] A computing device, the computing device includes a processor and a memory: the memory is used to store program codes and transmit the program codes to the processor; the processor is used to method of execution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com