Pile column connection precise positioning pouring system and construction method

A technology of precise positioning and construction method, which is applied in the direction of construction, sheet pile wall, foundation structure engineering, etc., to achieve the effect of facilitating adjustment control, easy adjustment and clamping and fixing, and saving construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

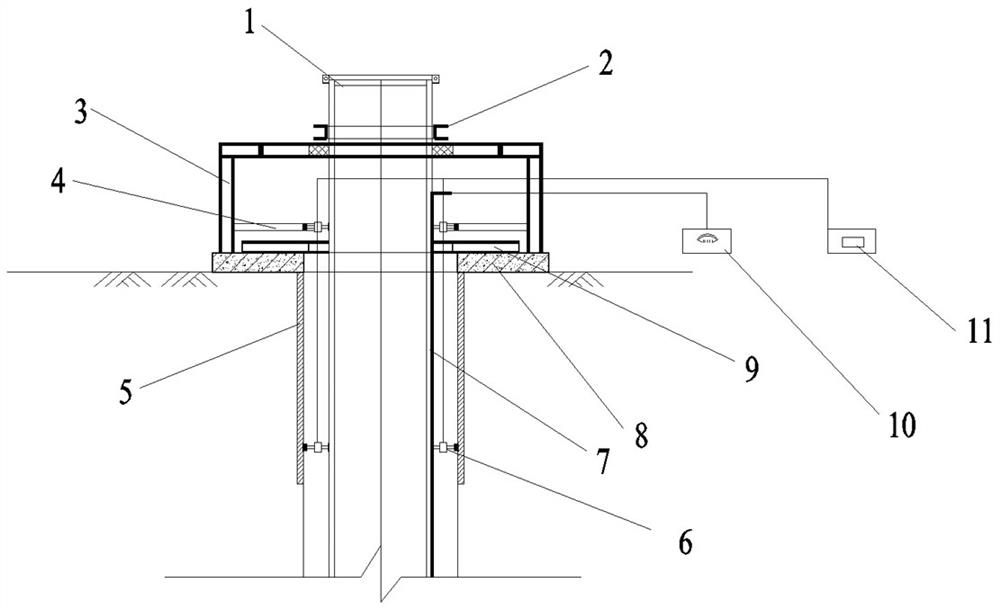

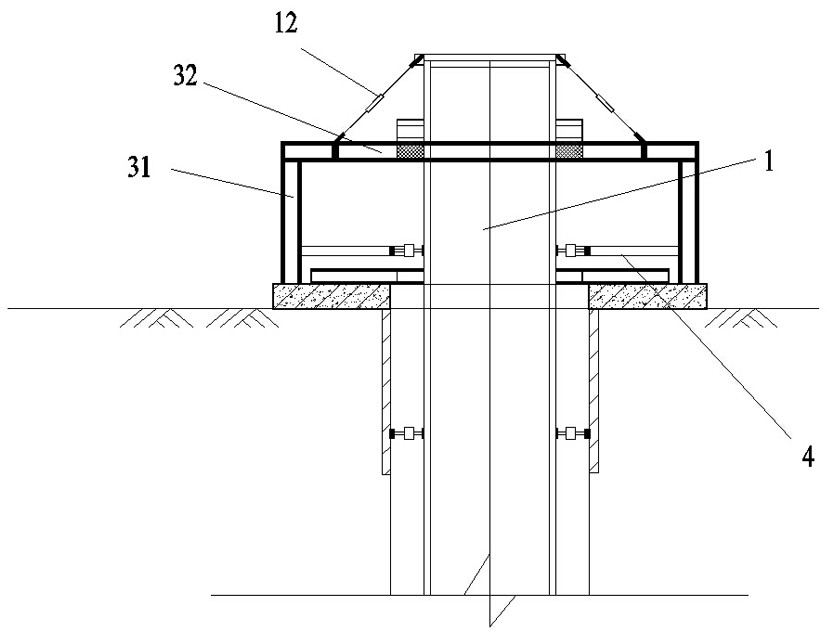

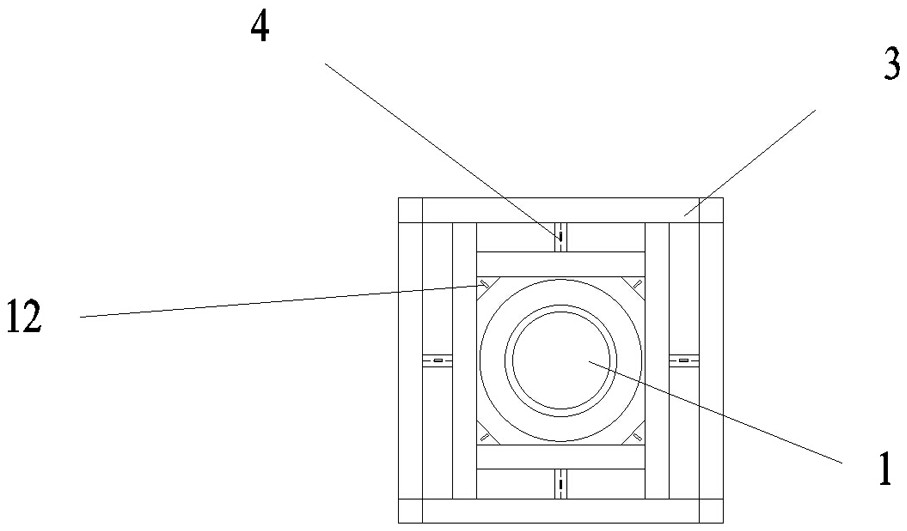

[0055] Taking a commercial building as an example, the building has three floors underground, including a parking garage, equipment rooms and two floors of commerce, and the seven floors above ground are commercial and commercial management rooms and warehouses. The overall construction technology of this project adopts the full reverse construction method, and the underground diaphragm wall (two walls combined into one) is used as the vertical enclosure structure around the foundation pit. The upside-down construction area utilizes structural beams and slabs as horizontal support members.

[0056] The foundation design grade of this project is Grade A, and the engineering piles are bored concrete pouring piles, with a pile diameter of 1200mm and 1500mm, a total of 131 piles, the bearing layer at the pile end is (5)-2 medium weathered andesite, and the pile length is about 23m. The elevation of the foundation floor is -15.7m, the thickness of the floor is 700mm, and the thickn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com