Fiber carrier for forming film based on microalgae adsorbed by straw as well as preparation method and application of fiber carrier

A straw fiber and carrier technology, applied in the application field of microalgae biotechnology, can solve the problems of poor reusability, inapplicability to large-scale, potential impact on algae growth, etc., achieve high feasibility of mechanized scale, and improve reusability Sex, the effect of improving the efficiency of microalgae cultivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

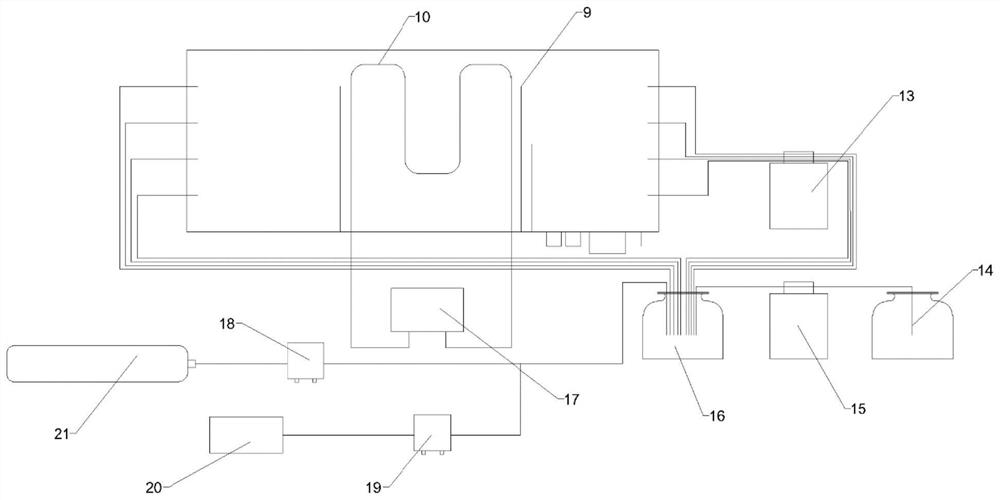

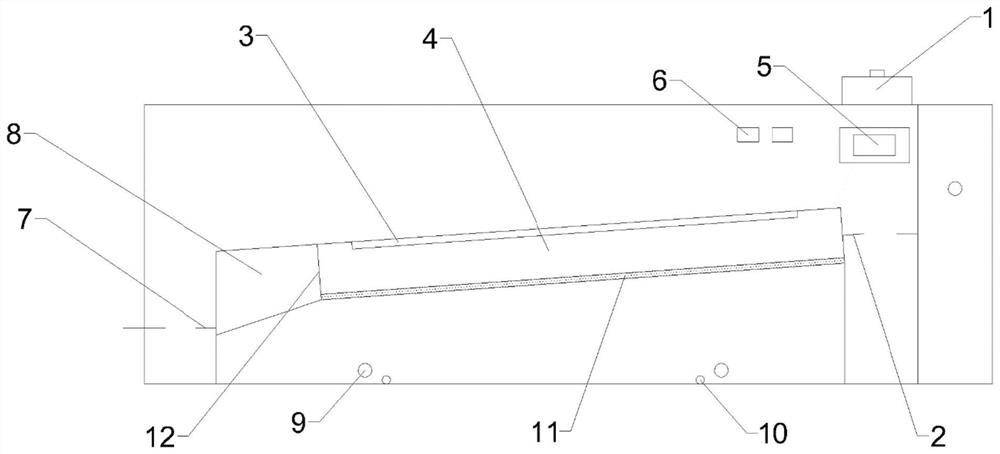

[0040] Below in conjunction with accompanying drawing, the present invention will be further described.

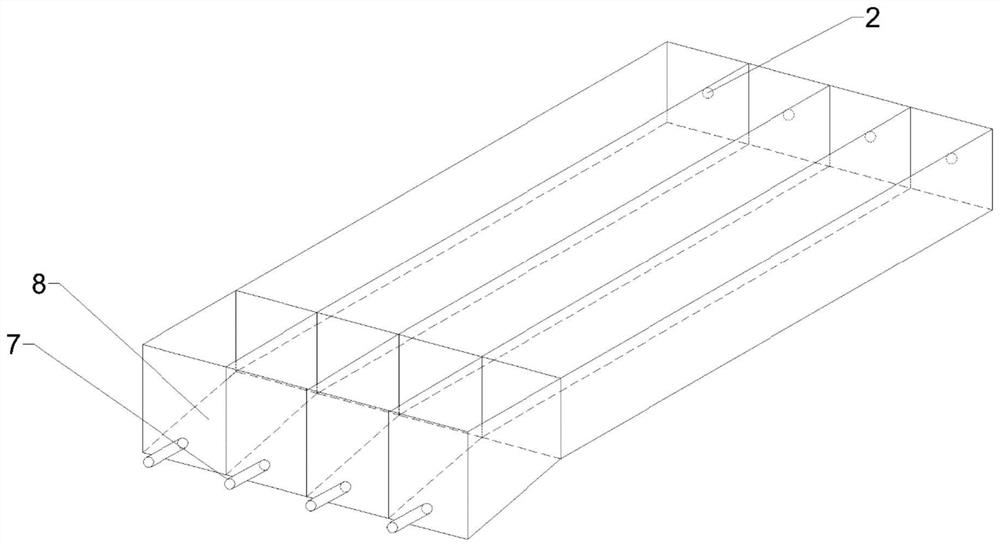

[0041] Based on straw adsorption microalgae film forming technology, the present invention has independently designed and developed a four-channel microalgae biofilm photobioreactor as a biofilm culture structure. Each channel is evenly laid with the same amount of straw carrier on the slope, and multi-algae species Mixed adherent film-forming cultures.

[0042] like Figure 1 to Figure 3 As shown, the reactor is mainly composed of an external constant temperature water bath and a biofilm culture liner, and the biofilm culture liner is placed in the external constant temperature water bath.

[0043] The external constant temperature water bath is constructed of polymethyl methacrylate (PMMA, plexiglass) plates, 65×25×20cm (length×width×height). The water bath is filled with 15.0L deionized water, and the water temperature is maintained at about 25.0±2.0°C under the actio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com