Acrylic emulsion for kraft paper as well as preparation method and application of acrylic emulsion

A technology of acrylic emulsion and kraft paper, used in papermaking, paper coatings, textiles and papermaking, etc., can solve the problem that the coating cannot be made into pulp, etc., and achieve the effect of avoiding surface migration, improving flexibility, and improving heat sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The application also provides a preparation method for acrylic emulsion for kraft paper, comprising the following steps:

[0034] Mixing 8-12 parts by weight of hard monomers, 6-10 parts by weight of soft monomers and 1-5 parts by weight of functional monomers to obtain mixed monomers;

[0035] Mixing 9.0-12 parts by weight of soft water and 0.3-2 parts by weight of emulsifier to obtain an emulsifier solution;

[0036] Mixing 13-16 parts by weight of soft water and 0.1-10 parts by weight of an initiator to obtain an initiator solution;

[0037] Mix 37-52 parts by weight of soft water, 15wt% of mixed monomers, 8wt% of emulsifier solution, and 4wt% of initiator solution to vacuumize, reheat, add remaining mixed monomers to the obtained mixed solution, emulsify Agent solution, initiator solution;

[0038] Add 3-8 parts by weight of modifying agent and 0.2-1.0 parts by weight of defoamer to the obtained mixed solution to obtain acrylic emulsion for kraft paper.

[0039] ...

Embodiment 1

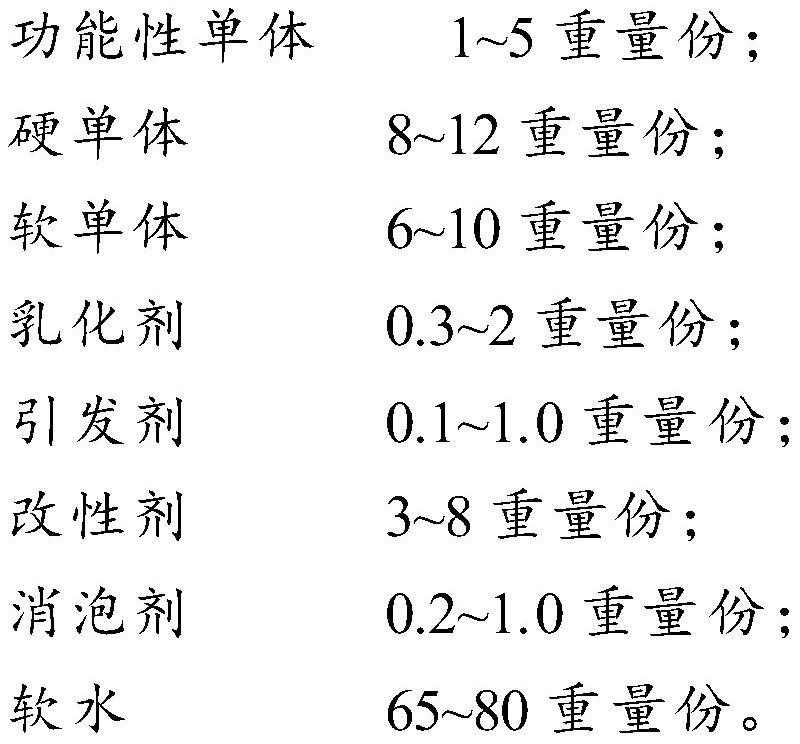

[0050] (1) Raw material ratio and specific type limitation:

[0051]

[0052] (2) Preparation method:

[0053] (1) Add hard monomer, soft monomer and functional monomer into material tank A, stir evenly at room temperature, make mixed monomer, and set aside;

[0054] (2) Part of soft water (accounting for 15% of the total amount) and emulsifier are added in the B feed tank, stirred evenly at room temperature, made into emulsifier solution, and set aside;

[0055] (3) part soft water (accounting for 20% of total amount) and initiator join in the C material tank, stir, are made into initiator solution, stand-by;

[0056] (4) Add the remaining soft water, 15% mixed monomer, 8% emulsifier solution, 4% initiator solution to the reactor, vacuumize to - (0.01-0.06) MPa after sealing, start stirring and heating device, the stirring speed is set at 150-200r / min, after the temperature reaches 85-90°C, keep warm for 0.5-1 hour, and continuously add the prepared mixed monomer, emulsi...

Embodiment 2

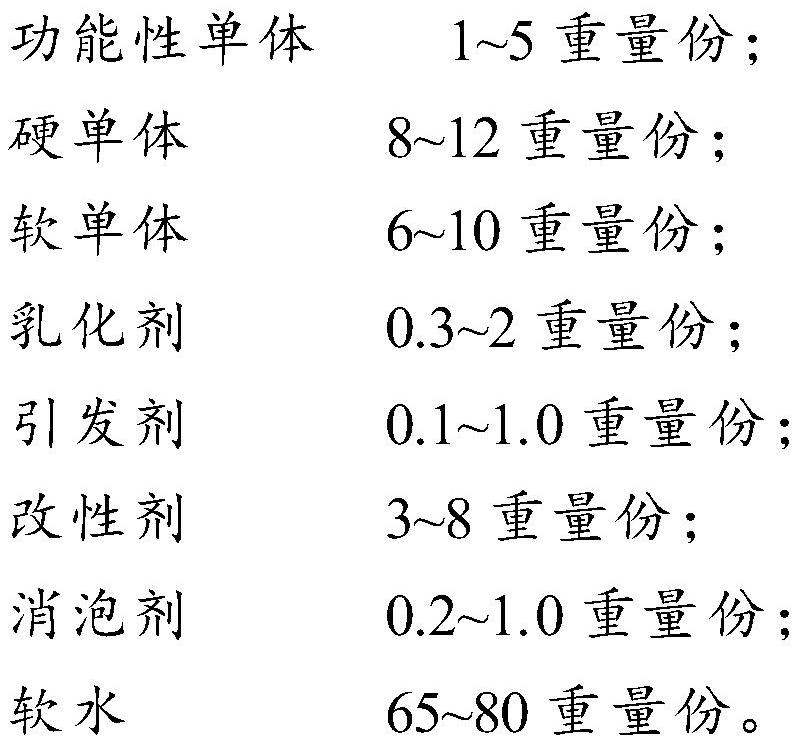

[0059] (1) Raw material ratio and specific type limitation:

[0060]

[0061] (2) Preparation method:

[0062] (1) Add hard monomer, soft monomer and functional monomer into material tank A, stir evenly at room temperature, make mixed monomer, and set aside;

[0063] (2) Part of soft water (accounting for 15% of the total amount) and emulsifier are added in the B feed tank, stirred evenly at room temperature, made into emulsifier solution, and set aside;

[0064] (3) part soft water (accounting for 20% of total amount) and initiator join in the C material tank, stir, are made into initiator solution, stand-by;

[0065] (4) Add the remaining soft water, 15% mixed monomer, 8% emulsifier solution, 4% initiator solution to the reactor, vacuumize to - (0.01-0.06) MPa after sealing, start stirring and heating device, the stirring speed is set at 150-200r / min, after the temperature reaches 85-90°C, keep warm for 0.5-1 hour, and continuously add the prepared mixed monomer, emulsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com