Composition and ceramic atomizing core thereof

A composition and atomizing core technology, applied in the field of electronic cigarettes, can solve the problems of uneven heating, easy overheating, and paste core, etc., and achieve the effect of avoiding uneven heating and improving heat transfer uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0083] According to the sixth aspect, in one embodiment, there is provided a method for preparing a porous heat-spreading layer, comprising: mixing the components of the composition described in the first aspect according to the formula amount to prepare a slurry, and mixing the slurry The material is coated on at least part of the surface of the substrate, heated and sintered to obtain the porous heat equalizing layer.

[0084] In one embodiment, the heating refers to sintering at 550-650°C.

[0085] In one embodiment, when heating, the sintering time at 550-650° C. is 15-60 minutes, preferably 30-60 minutes.

[0086] In one embodiment, when heating, the heating rate to the sintering temperature is 0.5-10° C. / min, preferably 2-7° C. / min.

[0087] In one embodiment, the substrate includes but not limited to a ceramic substrate.

[0088]In one embodiment, the present invention designs a structure with a porous oil-conducting layer, a heat generating sheet and a porous heat un...

Embodiment 1

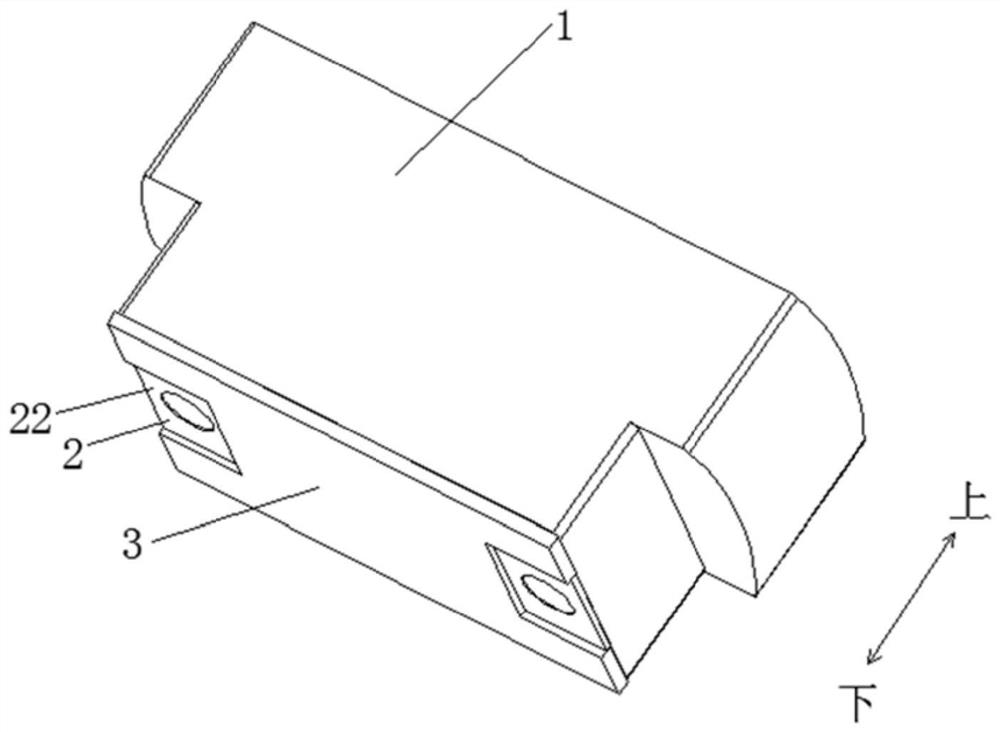

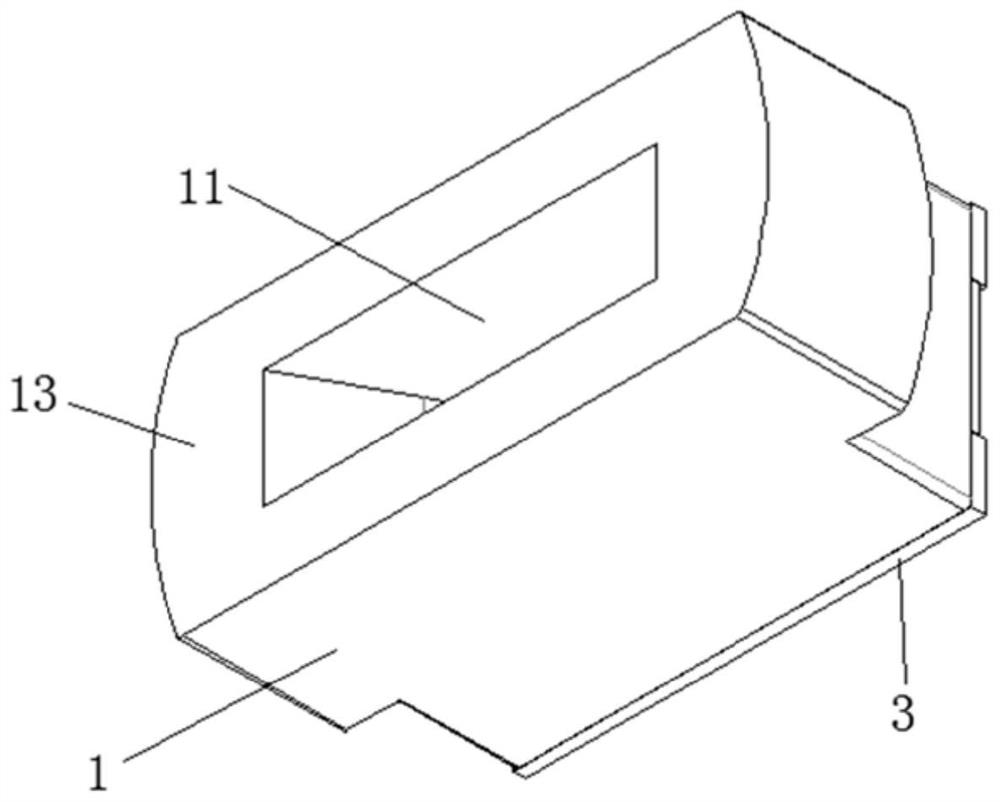

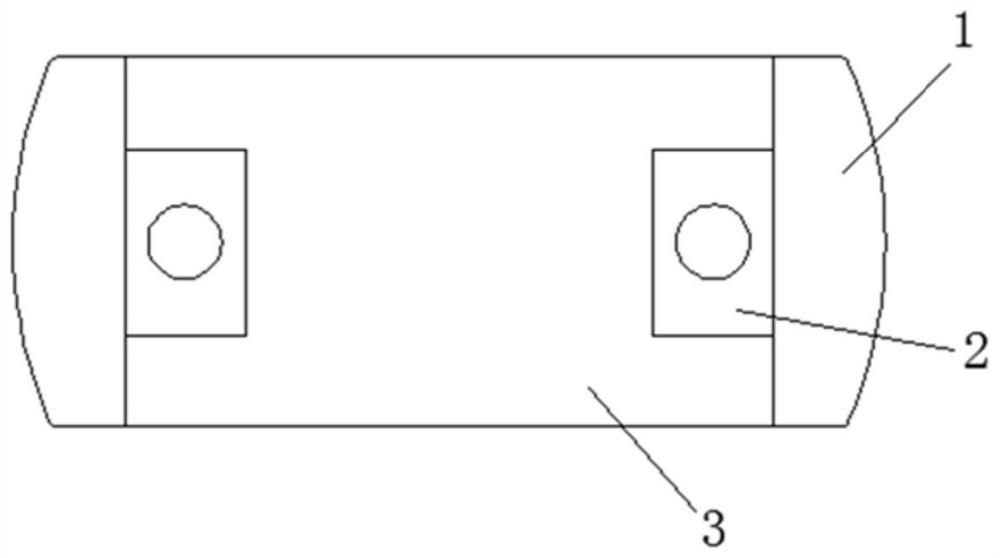

[0103] The porous ceramic atomizing core of this embodiment includes a ceramic substrate 1, a heating element 2 and a porous heat equalization layer 3, the ceramic substrate 1 is a porous oil-conducting structure, and the ceramic substrate 1 and the heating element 2 of the porous ceramic atomizing core of this embodiment The structural diagram of the reference Figure 16 , Figure 17 , the ceramic base 1 is in the shape of a square, the heating element 2 is completely embedded in the heat conducting surface 12 at the bottom of the ceramic base 1, the outer surface 23 of the heating element 2 is flush with the heat conducting surface 12 of the ceramic base 1, and the structural diagram of the porous heat equalizing layer 3 is shown in Figure 1 ~ Figure 4 , the porous heat equalizing layer 3 covers the entire heat conducting surface 12 including the heating element 2 , but does not cover the electrical connector 22 of the heating element 2 . The porous oil-conducting layer an...

Embodiment 2

[0109] The porous ceramic atomizing core of this embodiment includes a porous oil-conducting ceramic substrate 1, a heating element 2, and a porous heat equalizing layer 3. For the structural schematic diagram of the ceramic substrate 1 of the porous ceramic atomizing core of this embodiment, refer to Figure 16 , Figure 17 , in the shape of a square, the schematic diagram of the structure of the heating element 2 and the porous heat soaking layer 3 can be referred to Figure 5 ~ Figure 8 A part of the heating element 2 is embedded in the heat conducting surface 12 at the bottom of the ceramic substrate 1, and the other part protrudes from the heat conducting surface 12. The porous heat equalizing layer 3 covers the area not covered by the heating element 2 on the heat conducting surface 12. The porous heat equalizing layer 3 The outer surface is flush with the outer surface 23 of the heating element 2 .

[0110] Refer to Example 1 for the preparation method of the porous ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com