Material isothermal heating system for laboratory and control method thereof

A technology for isothermal heating and laboratory use, which is applied in the direction of laboratory equipment, heating or cooling equipment, chemical instruments and methods, etc. It can solve the problems of failure to achieve the experimental purpose and differences in material characteristics, so as to reduce the residence time and increase the accuracy. , to ensure the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

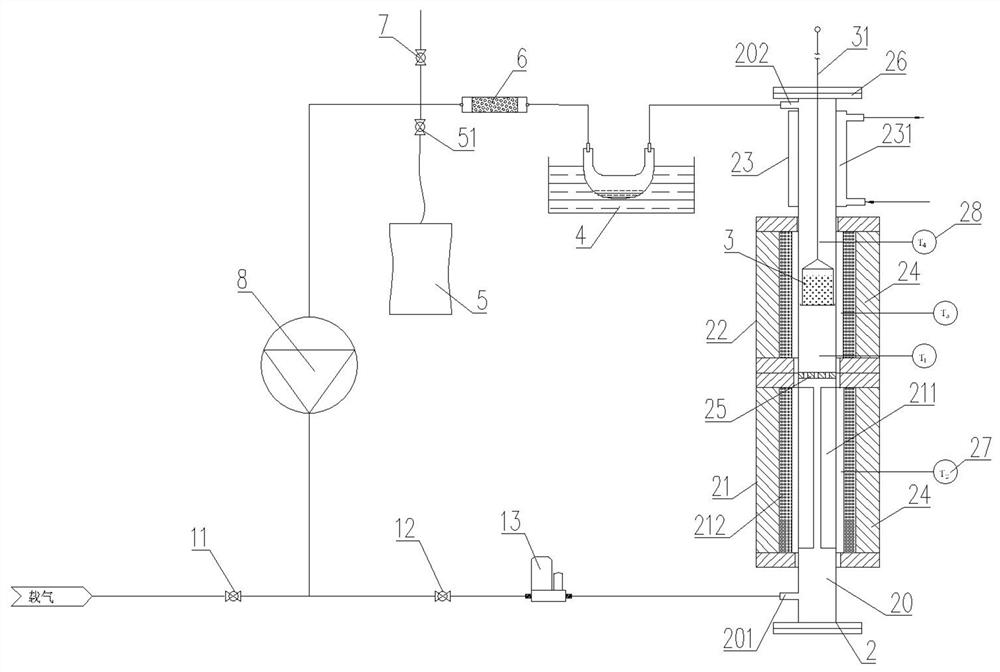

[0028] like figure 1 , The present invention proposes a laboratory materials isothermal heating system comprising a heating furnace 2 and a carrier gas circulation system; external source of carrier gas passes through the valve 12 communicates the heating furnace 11 and the first carrier the second carrier gas valve 2, the carrier gas inlet 201; carrier gas recirculation system 8 comprises a gas compressor, a reservoir bag 5, the filter 6 and the condenser 4 and the like, the carrier gas outlet 202 of the heating furnace 4 passes through the condenser, and a gas filter 6 the compressor 8 is connected between the two valves carrier. Filter 6 is also connected between the gas compressor and with a drain valve 8 of the intake valve 517 and the reservoir bag 5. Wherein the reservoir bag 5 during normal operation, the storage bag of the intake valve 515 is opened, the cycle is the carrier gas does not enter the reservoir bag 5, the storage bag 5 from the buffer; when the gas circulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com