Combined heat and power generation waste heat recovery system for data center cooling and control method

A technology of data center cooling and waste heat recovery system, applied in steam generation method using heat carrier, cooling/ventilation/heating transformation, machine operation mode, etc., can solve problems such as gaps, achieve thermal efficiency improvement, broad application prospects, The effect of improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0024] Example.

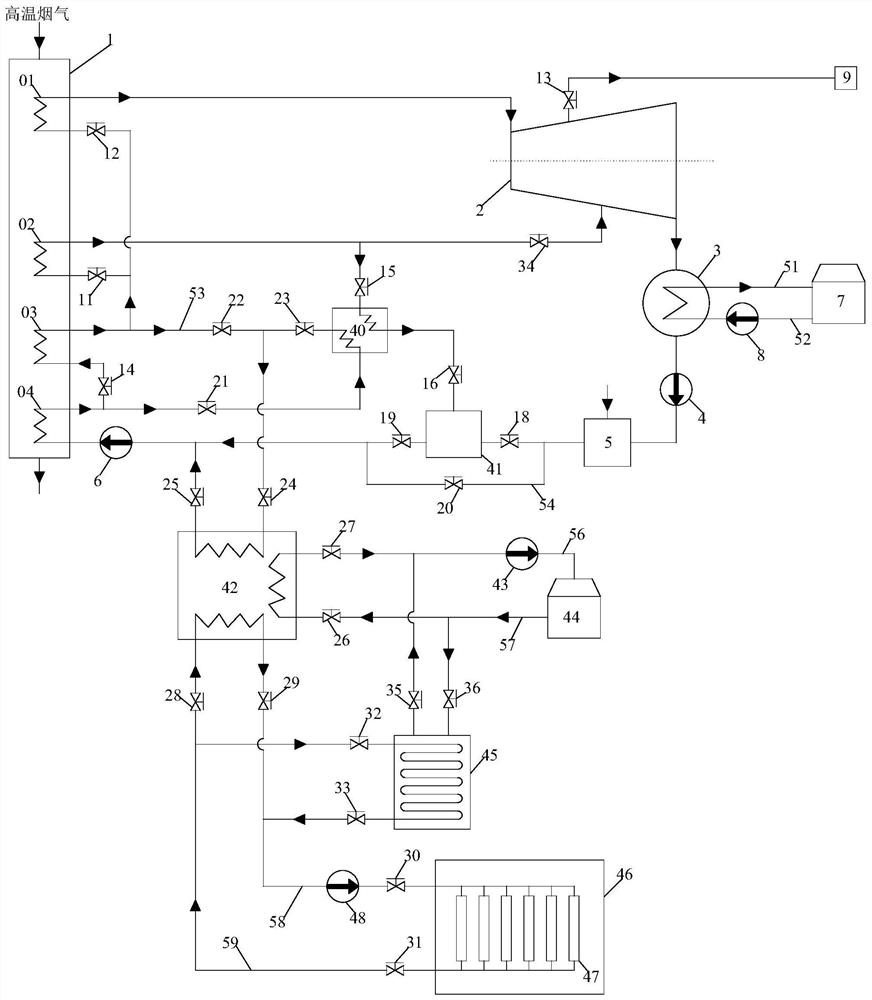

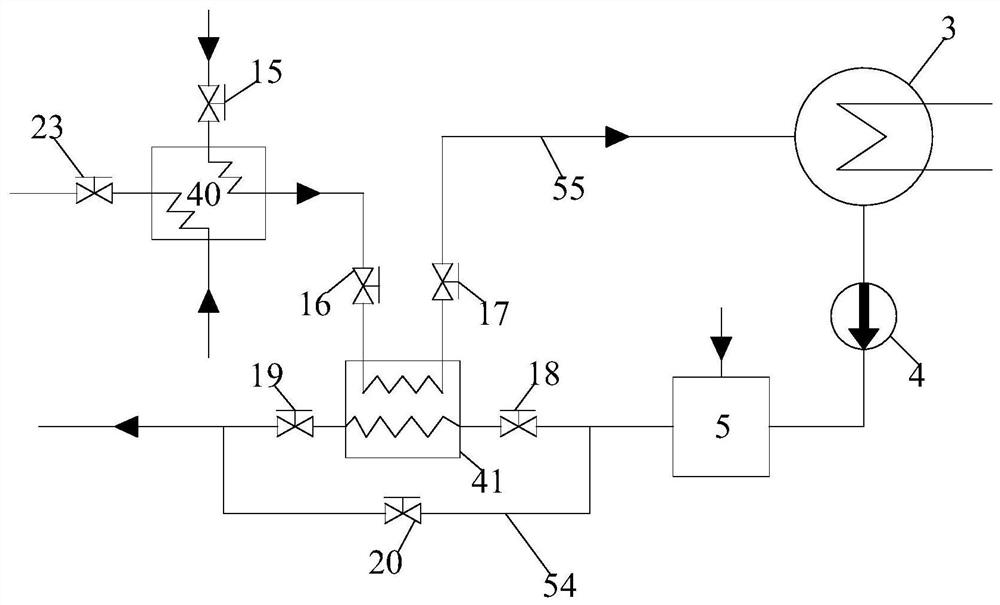

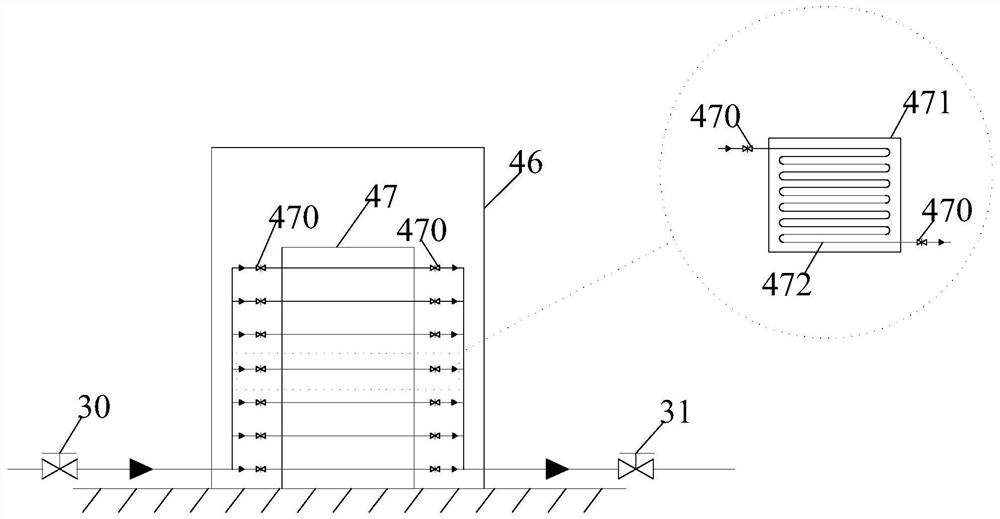

[0025] see figure 1 , in this embodiment, a cogeneration waste heat recovery system for data center cooling, including a waste heat boiler 1, a steam turbine unit 2, a condenser 3, a condensate pump 4, a shaft seal heater 5, a feed water pump 6, a A cooling tower 7, a first circulating water pump 8, and an industrial steam user 9, and the waste heat boiler 1 is provided with a high-pressure generator 01, a low-pressure generator 02, and an economizer 03 in sequence along the flue gas flow direction, and the high-temperature water of the economizer 03 The outlet is simultaneously connected to the high-temperature water inlet of the high-pressure generator 01 and the high-temperature water inlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com