Civil building fabricated wall based on BIM and construction method thereof

A civil construction and prefabricated technology, applied in the direction of construction, building components, building structure, etc., can solve the problem of easy generation of bubbles in the slurry, and achieve the effect of reducing the generation of bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

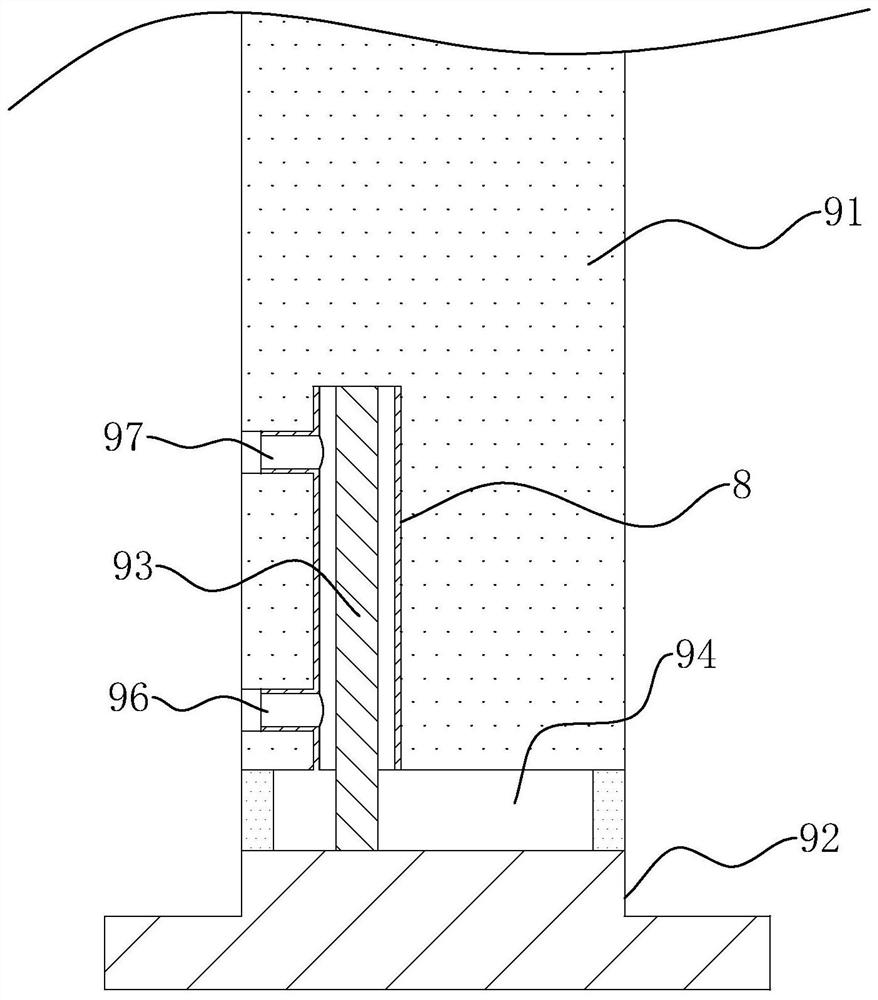

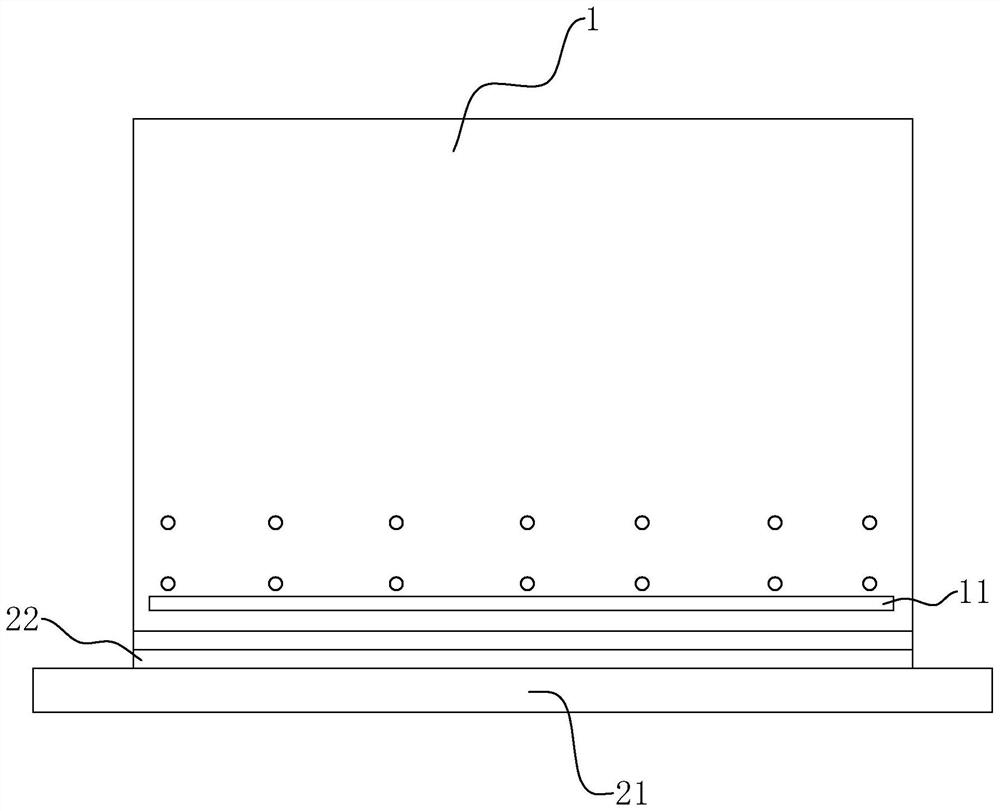

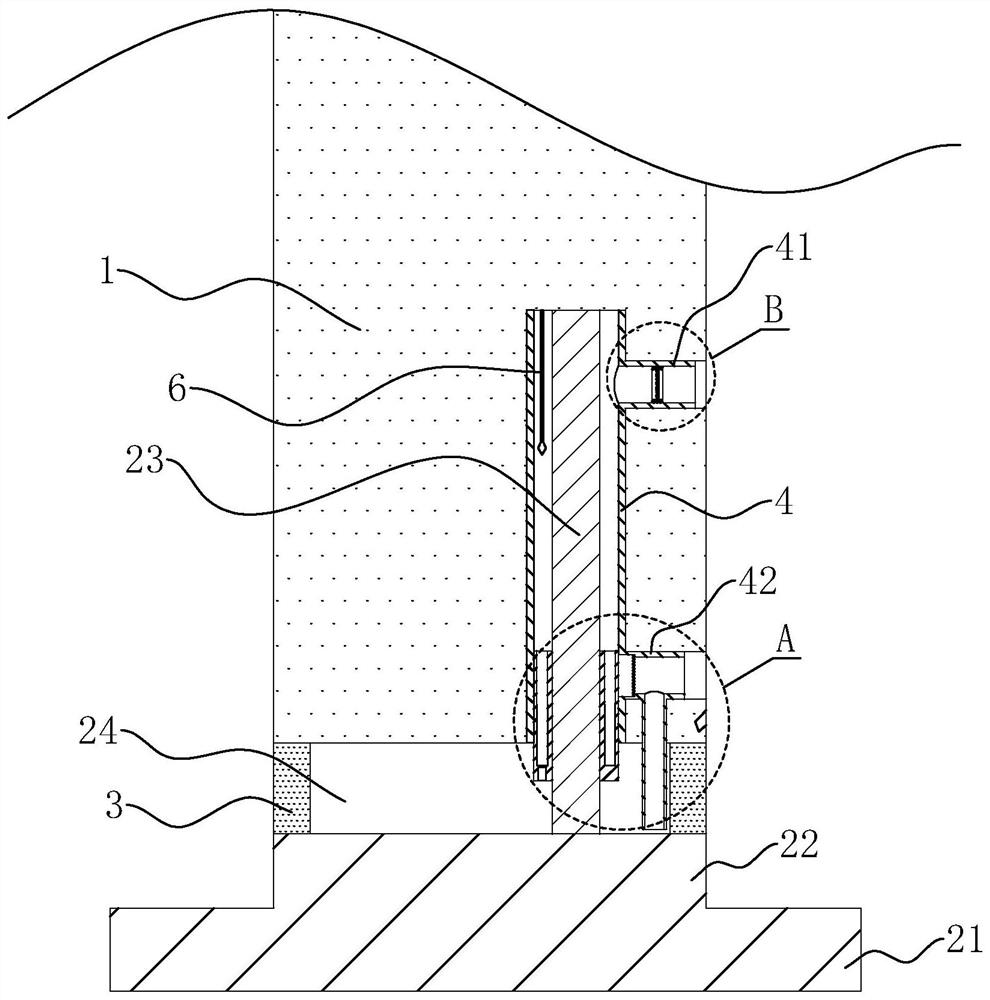

[0042] The embodiment of this application discloses a BIM-based prefabricated wall for civil buildings, refer to figure 2 , image 3, including the wall 1 arranged directly above the base 22 of the floor 21, the top of the base 22 is provided with a steel bar 23 with smooth surface, the edge between the wall 1 and the base 22 is surrounded by a circle of sealed concrete layer 3, the wall 1. A sealed grouting bin 24 is formed between the sealed concrete layer 3 and the base 22 . The position of the inner bottom of the wall 1 is pre-embedded with several grouting sleeves 4 along the width direction of the wall 1. The grouting sleeves 4 are arranged vertically. 23 is inserted into the corresponding grouting sleeve 4. The side wall of the grouting sleeve 4 is fixedly connected with a horizontal grouting tube 41 and a grouting tube 42 sequentially from top to bottom. One end of the grouting tube 41 communicates with the inside of the grouting sleeve 4, and the other end communic...

Embodiment 2

[0050] This embodiment discloses a construction method of a prefabricated wall of a civil building based on BIM, such as Figure 2-6 , including the following steps:

[0051] S1. Set the sealing ring 5 on the bottom of the steel bar 23 of the base 22 of the floor 21;

[0052] S2. Hoist the wall 1 pre-embedded with the grouting sleeve 4 to the top of the base 22, so that the distance between the bottom of the guide tube 43 and the top of the base 22 is 5 mm, and the overlong part of the guide tube 43 passes through the cutting machine Carry out cutting and removal, and insert the steel bar 23 into the corresponding grouting sleeve 4 at the same time;

[0053] S3, fixing the body of wall 1 on the floor 21 through the inclined support rod;

[0054] S4, push the sealing ring 5 upwards, so that the sealing ring 5 enters the grouting sleeve 4, and the sealing ring 5 seals the connection port between the grouting sleeve 4 and the grouting cylinder 42;

[0055] S5. Carry out sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com