Experimental paint washing basin

An experimental and coating technology, which is applied in the direction of filtration and separation, fixed filter elements, chemical instruments and methods, etc., can solve problems such as disadvantages, solvent splashing, and difficult pigment recovery work, and achieve the effect of reasonable design and reducing solvent splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

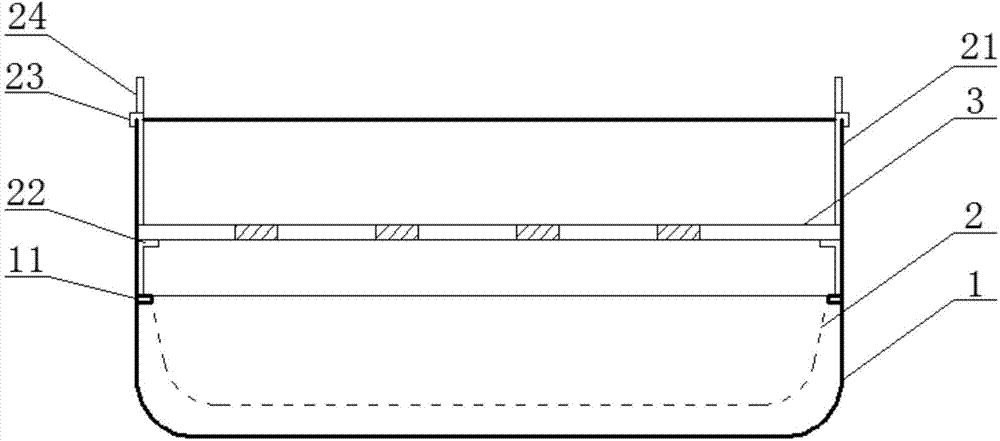

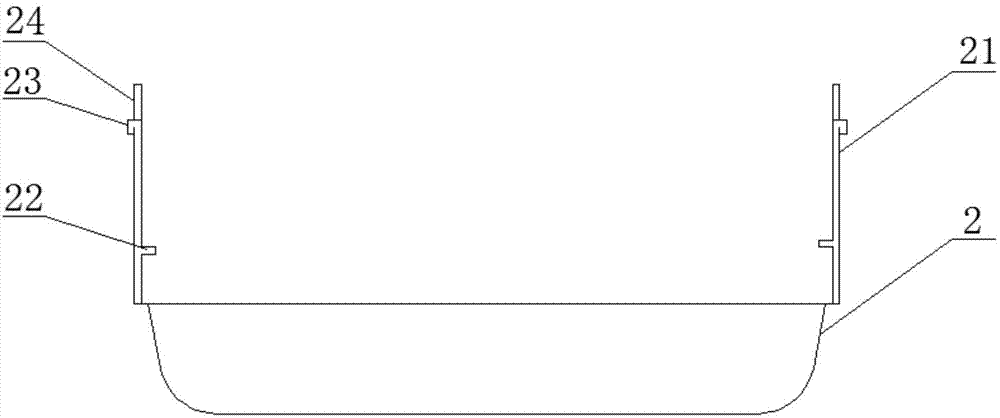

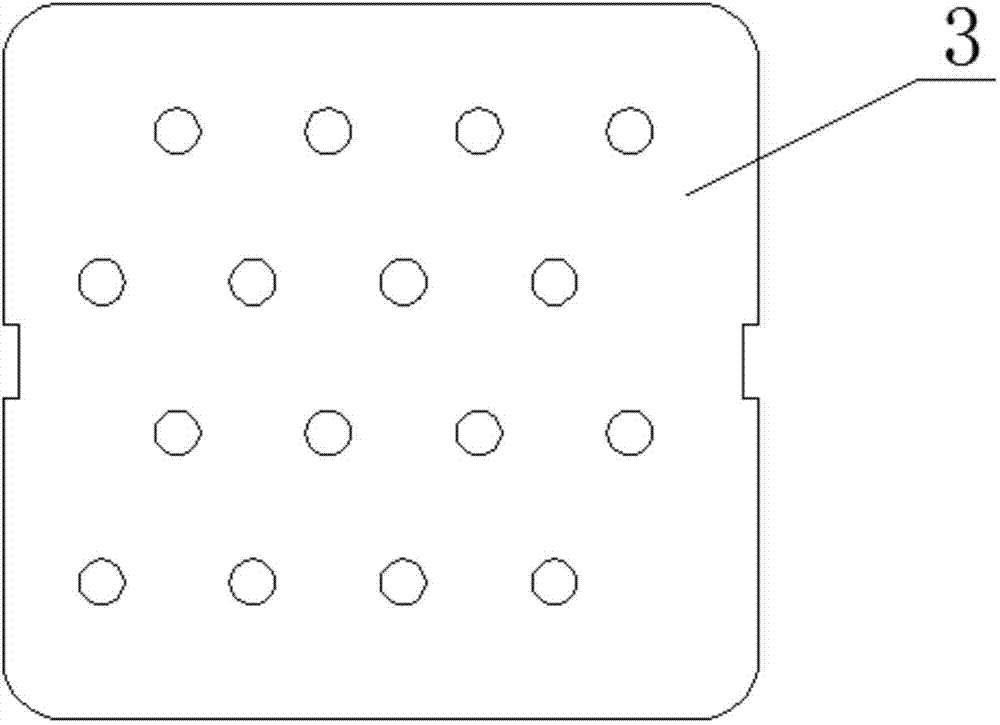

[0018] like Figure 1-4 As shown, a kind of experimental paint cleaning basin comprises a basin body 1, a collection box 2 and a baffle plate 3, and the outer edge of the collection box 2 is provided with several upwardly extending supports 21, and the collection box 2 can be moved through the support 21. The baffle plate 3 is located above the collection box 2 and is detachably mounted on the bracket 21. The baffle plate 3 is provided with a number of penetrating and uniformly arranged circular holes. In addition, the inner side of the basin 1 is provided with a clamping block 11 for clamping the collection box 2, the support 21 is also provided with a support block 22 for fixing the baffle 3, and the top of the support 21 is also provided with a clamping There are at least two brackets 21 for the slot 23 of the basin body 1 and the handle 24 for taking out the collection box 2 , and there are two brackets 21 in this embodiment.

[0019] When the pigment is recovered, the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com