Construction reinforcing platform for medium-and-small-span beam bridge

A technology of construction platform and reinforcement platform, applied in the direction of bridge reinforcement, bridges, bridge materials, etc., can solve the problems of time-consuming and laborious operation, low reliability, and expensive bridge inspection vehicles, and achieves simplified transportation channels and a wide range of applications. , the effect of high promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

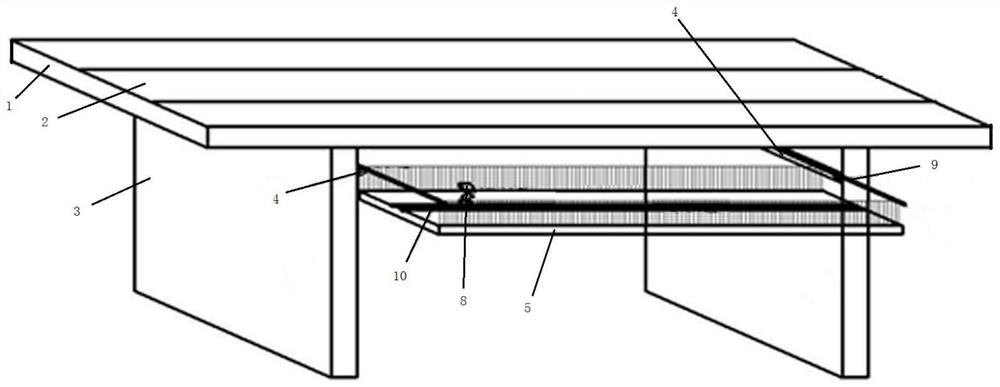

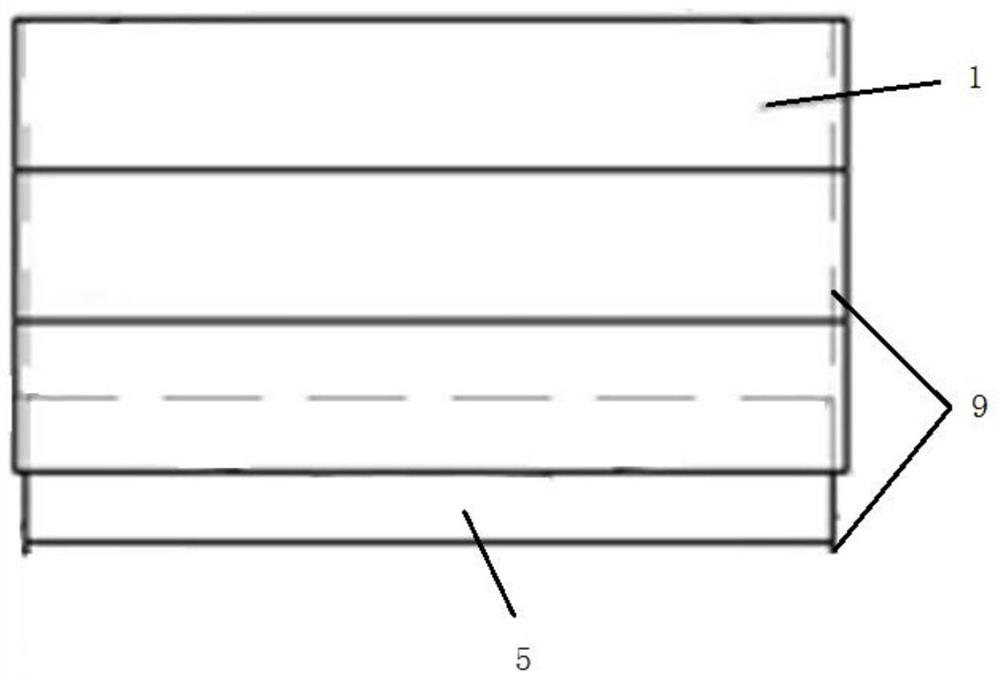

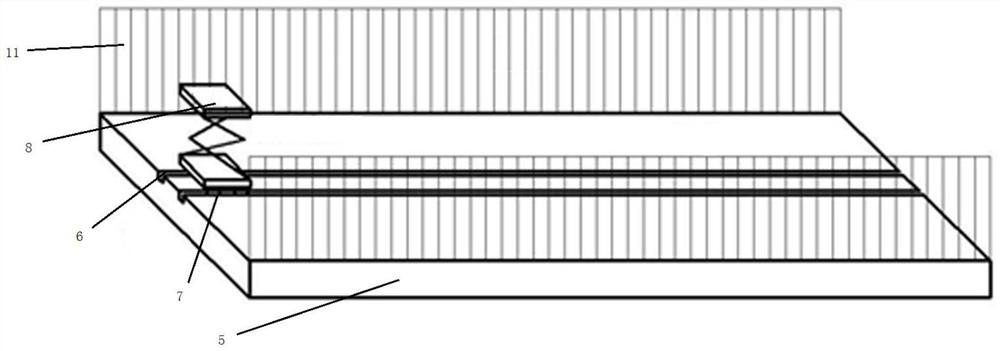

[0026] see Figure 1 to Figure 5 , in a preferred embodiment of the present invention, the small and medium-span girder bridge construction reinforcement platform includes a construction platform 5, the top surface of the construction platform 5 is provided with a track 6, and the track 6 is parallel to the construction platform 5 The length direction is arranged, and the sliding wheel 7 is installed rollingly on the track 6, and the jacking machine 8 is slidably installed through the sliding wheel 7, and the telescopic direction of the jacking machine 8 is the up and down direction, so that it can be lifted with a certain weight. Reinforcement materials such as steel sheet, etc., are convenient for construction workers, and the sliding design of the jacking machine 8 is convenient for pushing the jacking machine 8 to different positions, so that it is convenient to lift a certain weight at different positions on the construction platform 5. The bridge deck reinforcement mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com