Insulating paperboard production method capable of improving interlayer bonding capacity

An insulating paperboard and bonding ability technology, applied in pulp beating/refining methods, insulators, organic insulators, etc., can solve problems such as interlayer or end cracking, and achieve improved wire separation, good dispersion, and stable product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment one: Production of 3.0mm insulating cardboard

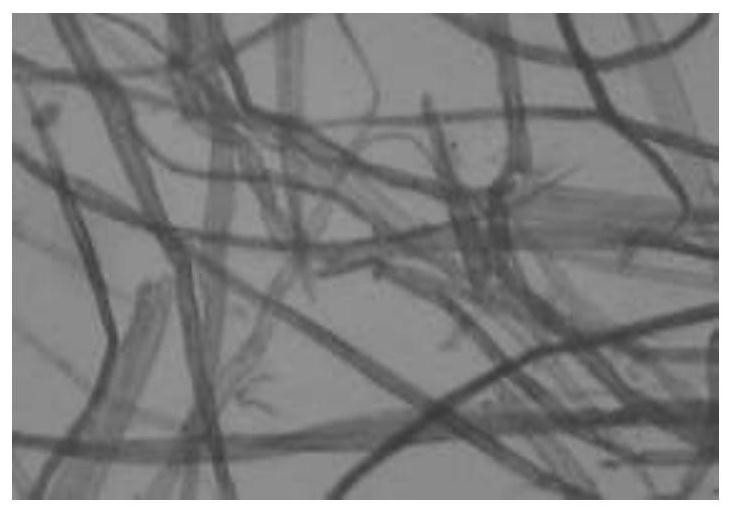

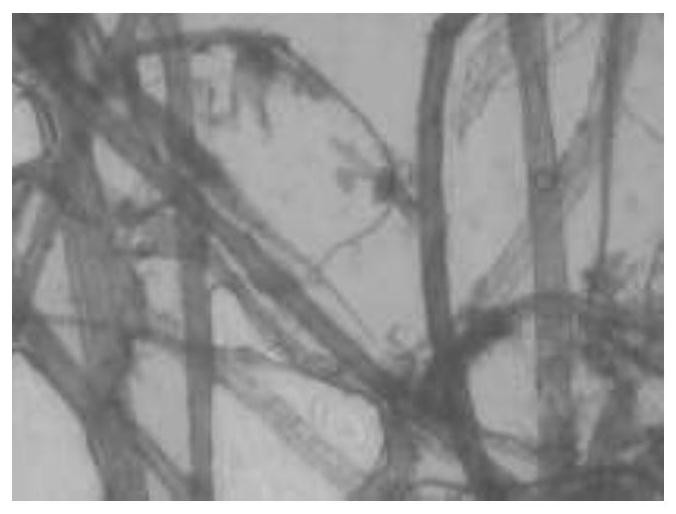

[0058] a. Beating: use imported unbleached kraft softwood pulp (70% Swedish Asba electronic-grade wood pulp+30% Canadian Prince George electronic-grade wood pulp) as raw material, then add white water (the weight percentage added is 94.5% for crushing) Pulp, the rest of the water is added during refining) for beating, disintegrate with a pulper, and form a slurry suitable for papermaking through the cutting, extrusion, rubbing and friction of the refiner;

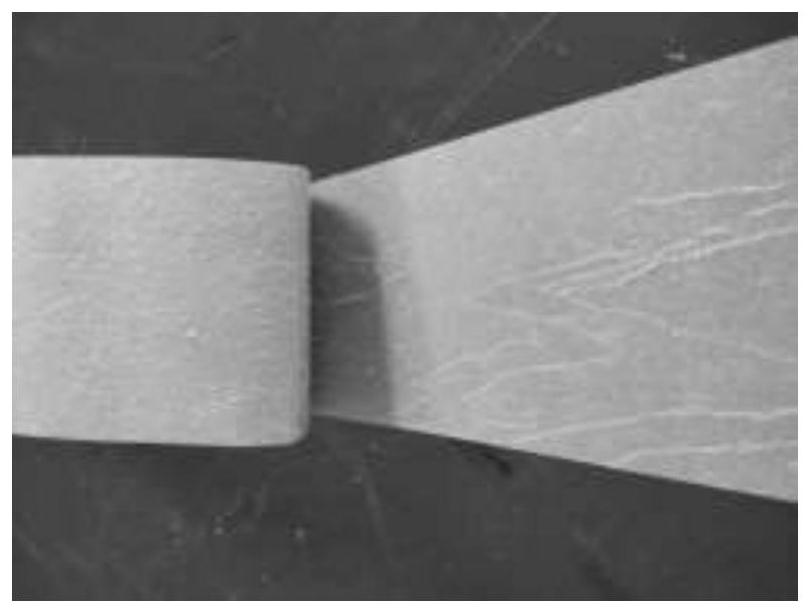

[0059] b. Paper forming: transport the prepared pulp in step a to the wet-sheet forming process for paper forming, adjust the appropriate pulp-to-net speed ratio (1.02~1.08), and the vertical and horizontal tension difference is small (≤1.5:1); adjust Wet paper page banner hanging amount, the deviation of the banner hanging amount is controlled at ±1.5%, and the banner hanging amount on both sides is a positive deviation, the paper thickness deviation mm (m...

Embodiment 2

[0063] Embodiment two: Production of 4.0mm insulating cardboard

[0064] a. Beating: use imported unbleached kraft softwood pulp (70% Swedish Asba electronic-grade wood pulp+30% Canadian Prince George electronic-grade wood pulp) as raw material, then add white water (the weight percentage added is 94.5% for crushing) Pulp, the rest of the water is added during refining) for beating, disintegrate with a pulper, and form a slurry suitable for papermaking through the cutting, extrusion, rubbing and friction of the refiner;

[0065] b. Paper molding: transport the pulp prepared in step a to the wet sheet forming process for paper molding, adjust the appropriate pulp-to-net speed ratio (1.02~1.08), and the vertical and horizontal tension difference is small (≤1.4:1); adjust Wet paper page banner hanging amount, the deviation of banner hanging amount is controlled at ±1.5%, and the banner hanging amount on both sides is a positive deviation, the paper thickness deviation mm (maxim...

Embodiment 3

[0069] Embodiment three: Production of 5.0mm insulating cardboard

[0070] a. Beating: use imported unbleached kraft softwood pulp (70% Swedish Asba electronic-grade wood pulp+30% Canadian Prince George electronic-grade wood pulp) as raw material, then add white water (the weight percentage added is 94.5% for crushing) Pulp, the rest of the water is added during refining) for beating, disintegrate with a pulper, and form a slurry suitable for papermaking through the cutting, extrusion, rubbing and friction of the refiner;

[0071] b. Paper forming: transport the pulp prepared in step a to the wet-sheet forming process for paper forming, adjust the appropriate pulp-net speed ratio (1.02~1.08), and the vertical and horizontal tension difference is small (≤1.3:1); adjust Wet paper page banner hanging amount, the deviation of the banner hanging amount is controlled at ± 1.5%, and the banner hanging amount on both sides is a positive deviation, the paper thickness deviation mm (m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com