Preparation method of water glycol fire-retardant hydraulic fluid

A water glycol and hydraulic fluid technology, applied in lubricating compositions, petroleum industry, etc., can solve the problems of decreased anti-rust performance, decreased viscosity retention, etc., to achieve the best low-temperature performance, excellent viscosity retention, and best anti-rust performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

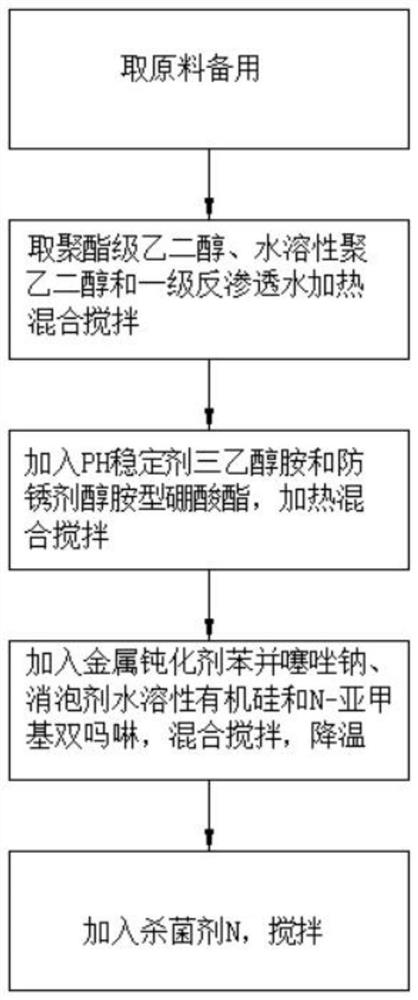

[0020] see figure 1 , the present invention provides a technical solution: a preparation method of water glycol flame retardant hydraulic fluid, the specific raw material composition ratio of the water glycol flame retardant hydraulic fluid includes: polyester grade ethylene glycol 30-40%, Water-soluble polyethylene glycol 10-18%, primary reverse osmosis water 35-48%, PH stabilizer triethanolamine 1-3%, rust inhibitor alcohol amine borate 1-2%, metal passivator benzene Sodium dithiazole 0.1-0.6%, defoamer water-soluble silicone 0.1-0.3%, fungicide N,N-methylenebismorpholine 1-2%;

[0021] The specific preparation method steps of the water glycol flame retardant hydraulic fluid are as follows:

[0022] Step 1: Take polyester grade ethylene glycol 30-40%, water-soluble polyethylene glycol 10-18%, primary reverse osmosis water 35-48%, PH stabilizer triethanolamine 1-3%, rust inhibitor alcohol Amine borate 1-2%, metal deactivator benzothiazole sodium 0.1-0.6%, defoamer water-sol...

Embodiment 1

[0031] The specific preparation method steps of the water glycol flame retardant hydraulic fluid are as follows:

[0032] Step 1: Take 30% of polyester grade ethylene glycol, 10% of water-soluble polyethylene glycol, 35% of primary reverse osmosis water, 1% of pH stabilizer triethanolamine, 1% of rust inhibitor alcohol amine type borate, Metal deactivator benzothiazole sodium 0.1%, defoamer water-soluble silicone 0.1%, and fungicide N,N-methylenebismorpholine 1% are placed for later use;

[0033] Step 2: Take polyester grade ethylene glycol, water-soluble polyethylene glycol and primary reverse osmosis water and pour them into the container respectively, and heat the mixture continuously through the heating device. When the temperature of the mixture rises to 50 degrees Celsius, the Stir for 30min;

[0034] Step 3: Add pH stabilizer triethanolamine and rust inhibitor alcoholamine borate to the mixture obtained in step 2, increase the reaction temperature to 70 degrees Celsius...

Embodiment 2

[0038] The specific preparation method steps of the water glycol flame retardant hydraulic fluid are as follows:

[0039]Step 1: Take 35% of polyester grade ethylene glycol, 14% of water-soluble polyethylene glycol, 42% of primary reverse osmosis water, 2% of pH stabilizer triethanolamine, 1.5% of rust inhibitor alcohol amine type borate, Metal deactivator benzothiazole sodium 0.3%, defoamer water-soluble silicone 0.2%, bactericide N,N-methylenebismorpholine 1.5% and put aside for later use;

[0040] Step 2: Take polyester-grade ethylene glycol, water-soluble polyethylene glycol and primary reverse osmosis water and pour them into the container respectively, and heat the mixture continuously through the heating device. When the temperature of the mixture rises to 55 degrees Celsius, the Stir for 35 minutes;

[0041] Step 3: Add pH stabilizer triethanolamine and rust inhibitor alcoholamine borate to the mixture obtained in step 2, increase the reaction temperature to 80 degree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com