Integrated circuit plastic packaging film injection equipment

A technology of integrated circuits and injection equipment, applied in the field of integrated circuit plastic film injection equipment, can solve problems such as failure of injection tube failure warning, affecting other chip packaging, affecting normal startup injection, etc., to achieve fast replacement, easy disassembly and maintenance. , the effect of quick replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

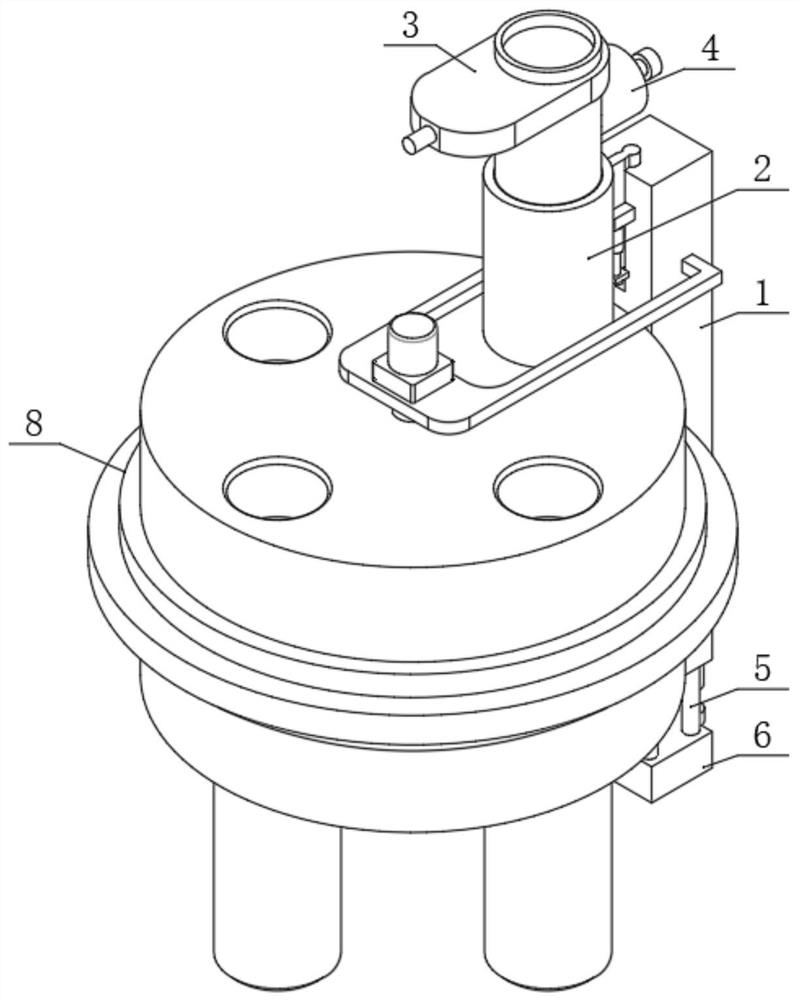

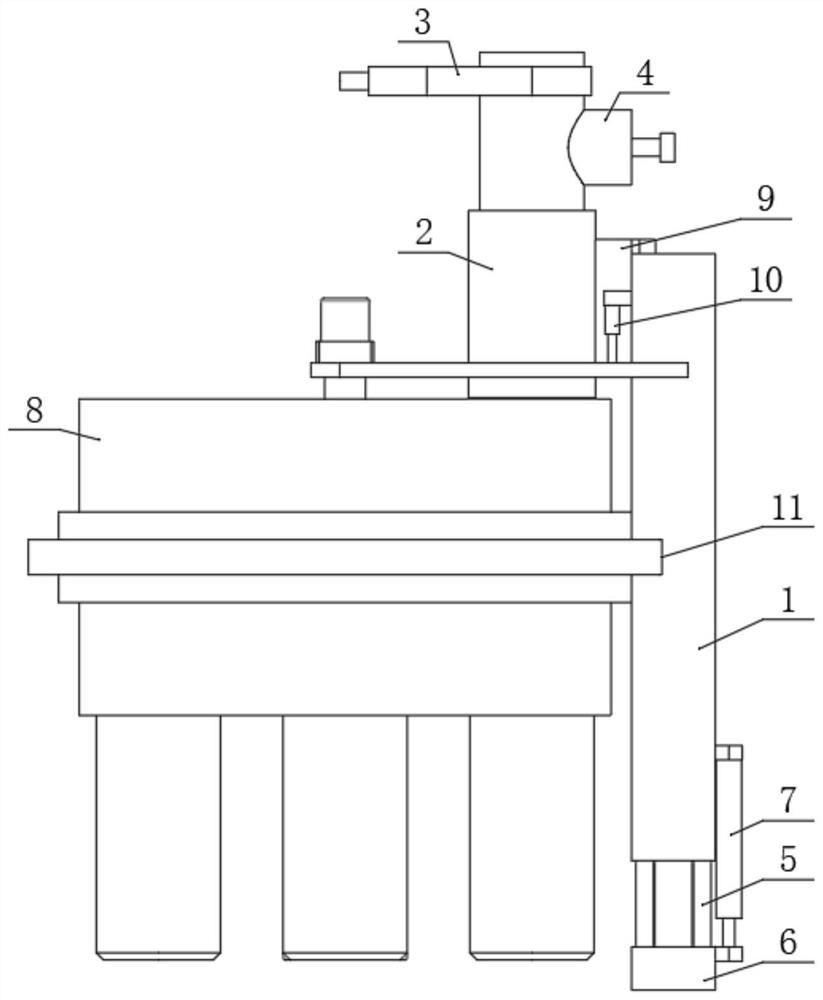

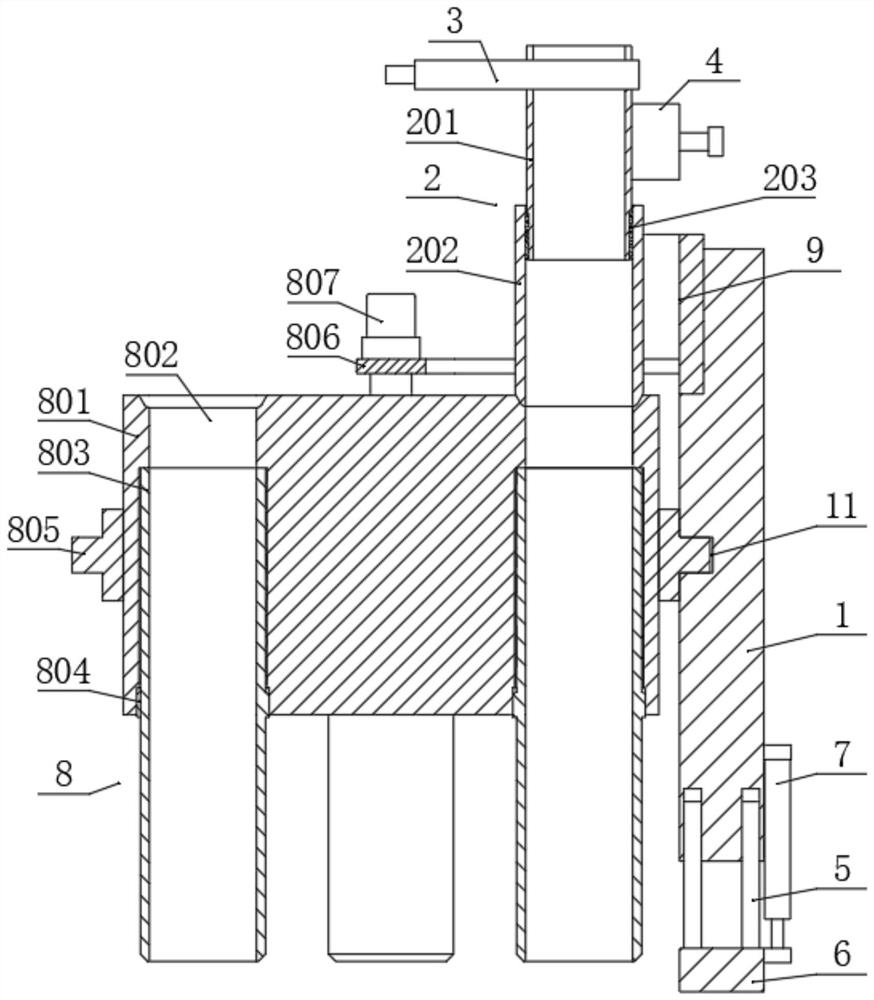

[0024] see Figure 1-2 , integrated circuit plastic film injection equipment, including a support rod 1, a telescopic tube 2 and a quick-change tube assembly 8, the telescopic tube 2 is arranged above the quick-change tube assembly 8, and the side wall of the telescopic tube 2 assembly Slidingly connected to the side wall of the support rod 1, the quick tube change assembly 8 is rotatably connected to the side wall of the support rod 1, the middle part of the telescopic tube 2 is provided with a quick closing component 3, and the telescopic tube The side wall of 2 communicates with a blockage alarm assembly 4, and the second end of the support rod 1 is provided with two or more than two slide holes, and a slide bar 5 is slidably connected in the slide hole, and the slide bar The second end of 5 is fixedly connected with a base 6 , the side wall of the base 6 is fixedly connected with a first cylinder 7 , and the other end of the first cylinder 7 is fixedly connected with the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com