Preparation device and preparation method of aggregate composite cemented concrete for road repairing

A preparation device and concrete technology, applied in the direction of clay preparation device, mixing operation control device, unloading device, etc., to improve the overall performance, avoid rain erosion, and improve the organic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

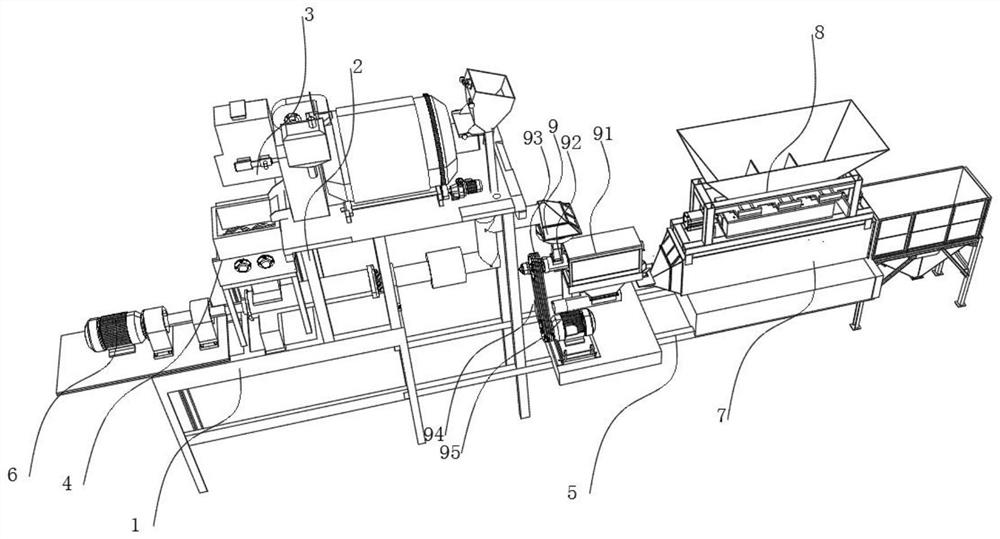

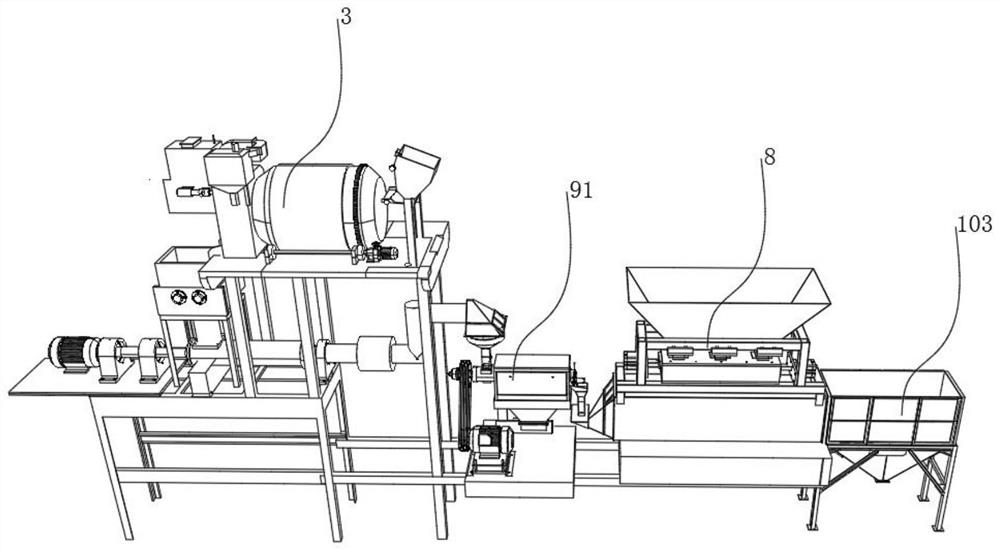

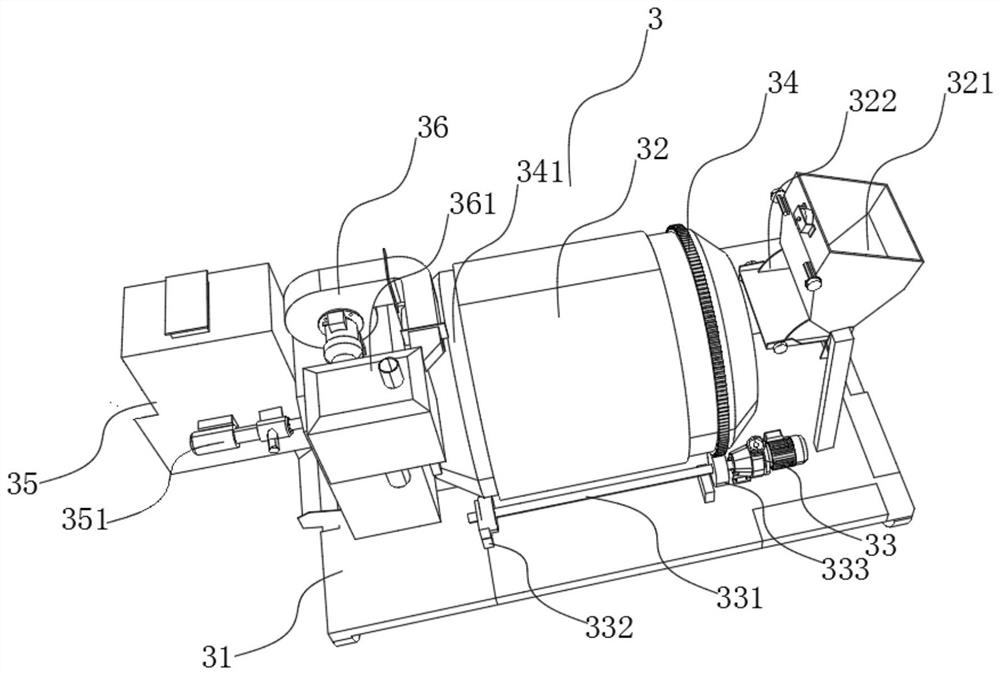

[0051] see Figure 1-9 , the present invention provides a technical solution: an aggregate composite cemented concrete preparation device for road repair, which includes a first fixed frame 1, a mixing mechanism 3, a crushing mechanism 4, a grinding mechanism 6, a uniform mixing mechanism and a temperature control mechanism 7. The top of the first fixed frame 1 is fixed with the second fixed frame 2, the top of the second fixed frame 2 is fixed with the mixing mechanism 3, the top of the first fixed frame 1 is fixed with the crushing mechanism 4, the first fixed One side of frame 1 is fixedly installed with the third fixed frame 5, and the top of the third fixed frame 5 is fixedly installed with grinding mechanism 6, and one side of grinding mechanism 6 is fixedly installed with uniform stirring mechanism, and one side of uniform stirring mechanism is provided with The temperature control mechanism 7, the top of the temperature control mechanism 7 is fixedly equipped with a qu...

Embodiment 2

[0062] A method for preparing aggregate composite cemented concrete for road repair, comprising the following steps:

[0063] Step 1: Selection of raw materials: 150-250 parts of cement, 50-100 parts of asphalt, 100-150 parts of 100-mesh fine sand, 20-30 parts of improved additives, 5-10 parts of bentonite grafted hydrophobic agent, 1-10 parts of activated kaolin parts, 2-6 parts of basalt fiber;

[0064] Step 2: Add the raw materials of Step 1 into the mixing shell 32, and drive the rolling gear 333 on the rotating shaft 331 to rotate through the rotation of the two first driving motors 33 provided, and drive the rolling gear 333 under the action of the driving force The rotation is convenient to the rack 34 on the mixing housing 32 and the slide rail 341 are rolled and connected, so that the aggregate of the road repair inside the mixing housing 32 is mixed and stirred;

[0065] Then, the rotation of the first drive motor 33 drives the stirring blade 37 to mix and stir the ...

Embodiment 3

[0076] Same as embodiment 2 concrete preparation method;

[0077]The preparation method of the improved additive is:

[0078] S1: Mix rare earth lanthanum chloride with a mass fraction of 60% and polyethylene glycol emulsifier in a weight ratio of 1:2, then stir at a speed of 150r / min for 25min, and then add nano-calcium carbonate with a mass fraction of 15 solution, continue to stir for 15 minutes, and the stirring is completed to obtain the amphoteric solution;

[0079] S2: Feed the nano-silica into the sodium alginate solution and stir at a low speed for 15 minutes at a stirring speed of 150r / min to prepare a nano-silica solution; wherein the sodium alginate solution is sodium alginate and hydrochloric acid at a weight ratio of 1 :3 mixed and prepared;

[0080] S3: Mix the amphoteric solution and the nano-silica solution at a weight ratio of 1:3, and then carry out ultrasonic dispersion. The ultrasonic power is 300W, and the ultrasonic time is 25 minutes. After the ultras...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com