Production method of squatting pan capable of being automatically produced and squatting pan

A production method and technology of squatting toilets, which are applied to flushing equipment with water tanks, manufacturing tools, water supply devices, etc., can solve problems such as poor flushing effect, inconvenient use for users, and water dispersion, so as to improve bonding efficiency and bonding Quality, Yield Improvement, Fast Alignment Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings. It is only stated here that the words for directions such as up, down, left, right, front, back, inside, and outside that appear or will appear in the text of the present invention are only based on the accompanying drawings of the present invention, and are not specific to the present invention. limited.

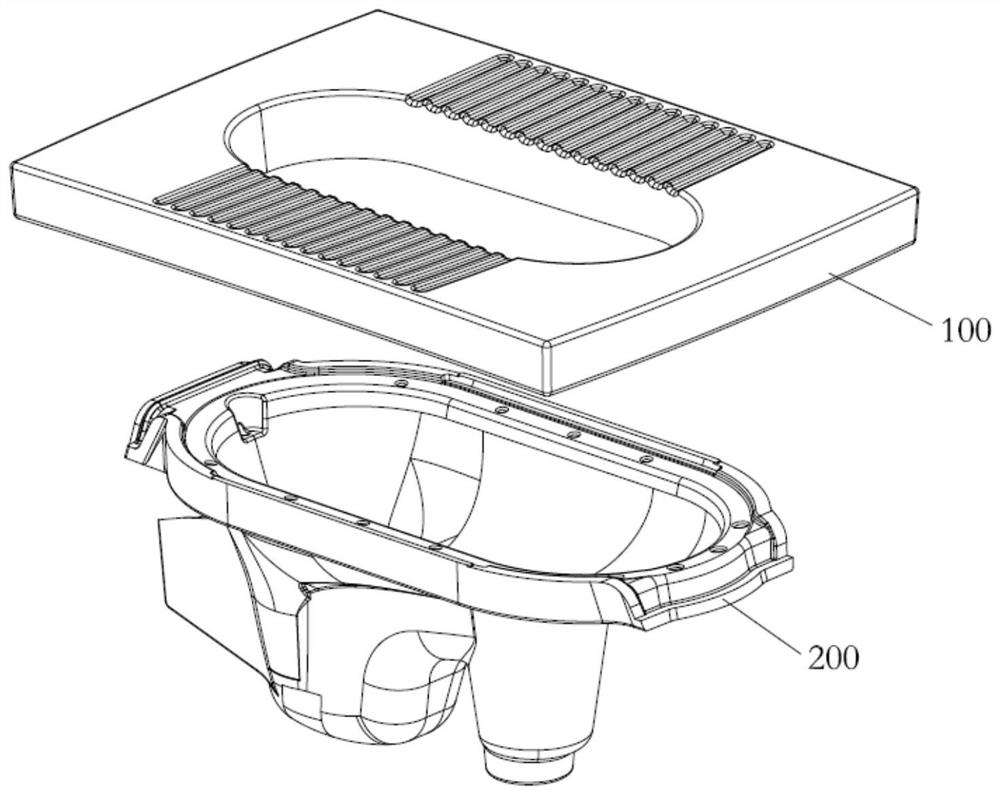

[0037] The present invention also provides a production method of a squatting pan that can be automatically produced, comprising the following steps:

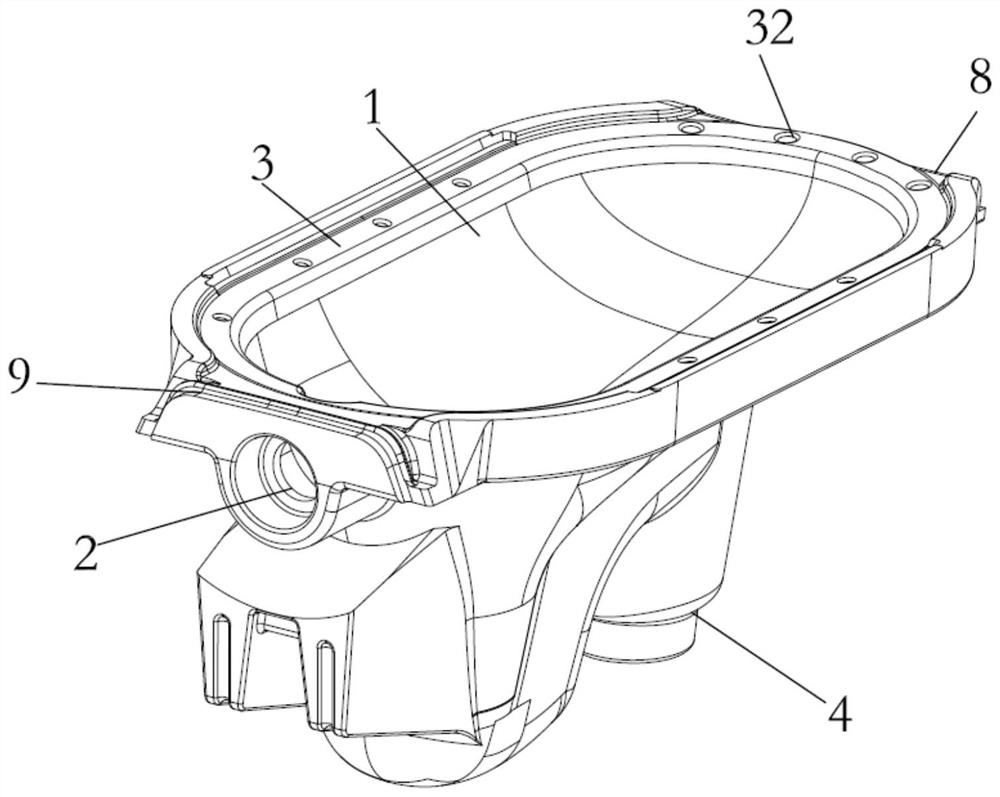

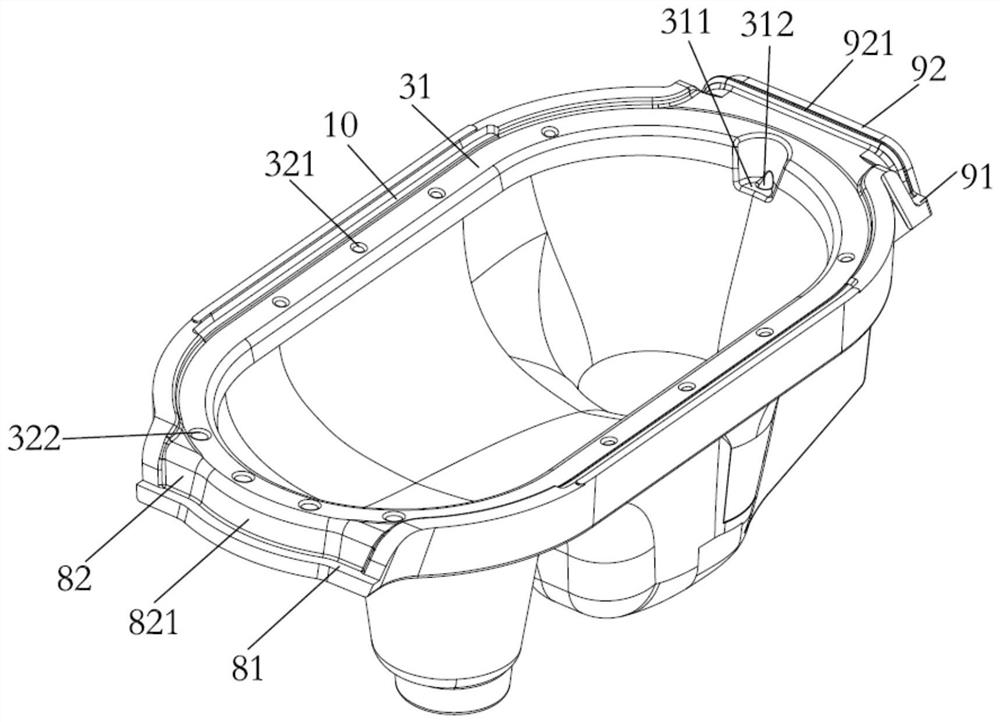

[0038] S01. Generate the bladder body 100 through a high-pressure grouting mold. The bladder body 100 includes a bladder body 1 , a water inlet 2 , a flushing portion 3 and a sewage pipe 4 , and the flushing portion 3 includes a water guiding cavity 31 and a water distribution hole 32 . It should be noted that, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com