Noise reduction and dust removal electric drill with scrap collecting structure and control method of noise reduction and dust removal electric drill

An electric drill and noise reduction technology, which is applied in the direction of manufacturing tools, portable drilling rigs, drilling/drilling equipment, etc., can solve the problems of weakening the noise reduction effect and blockage of the telescopic cover, so as to ensure the comfort of use, convenient disassembly, and benefit The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

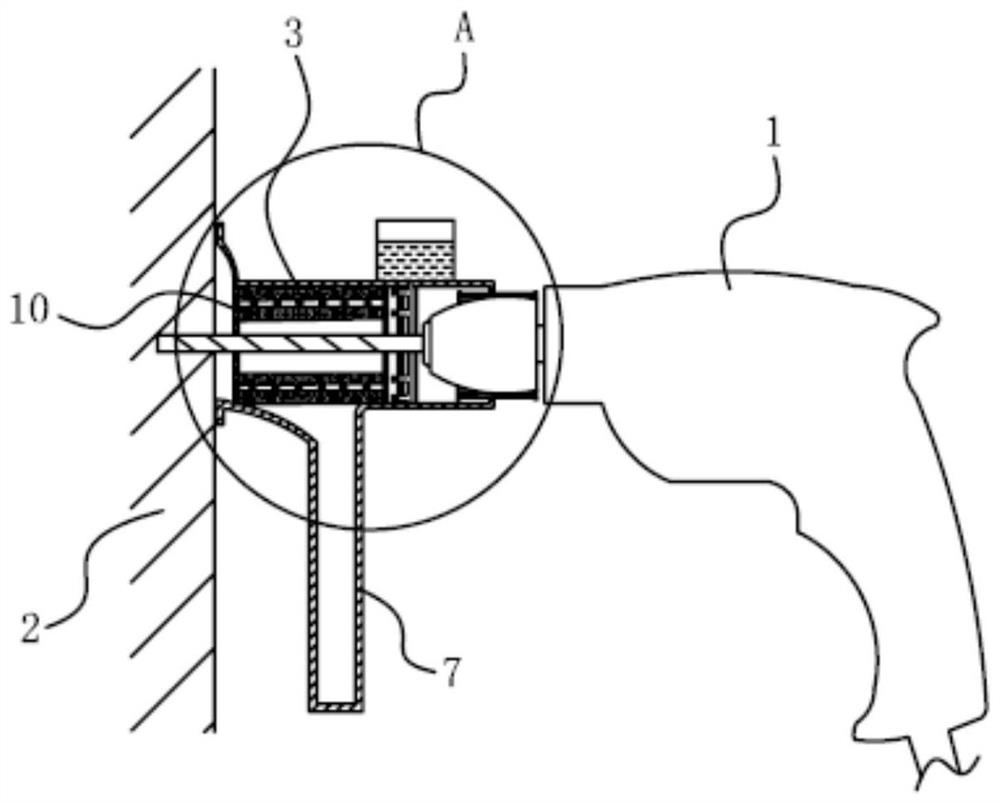

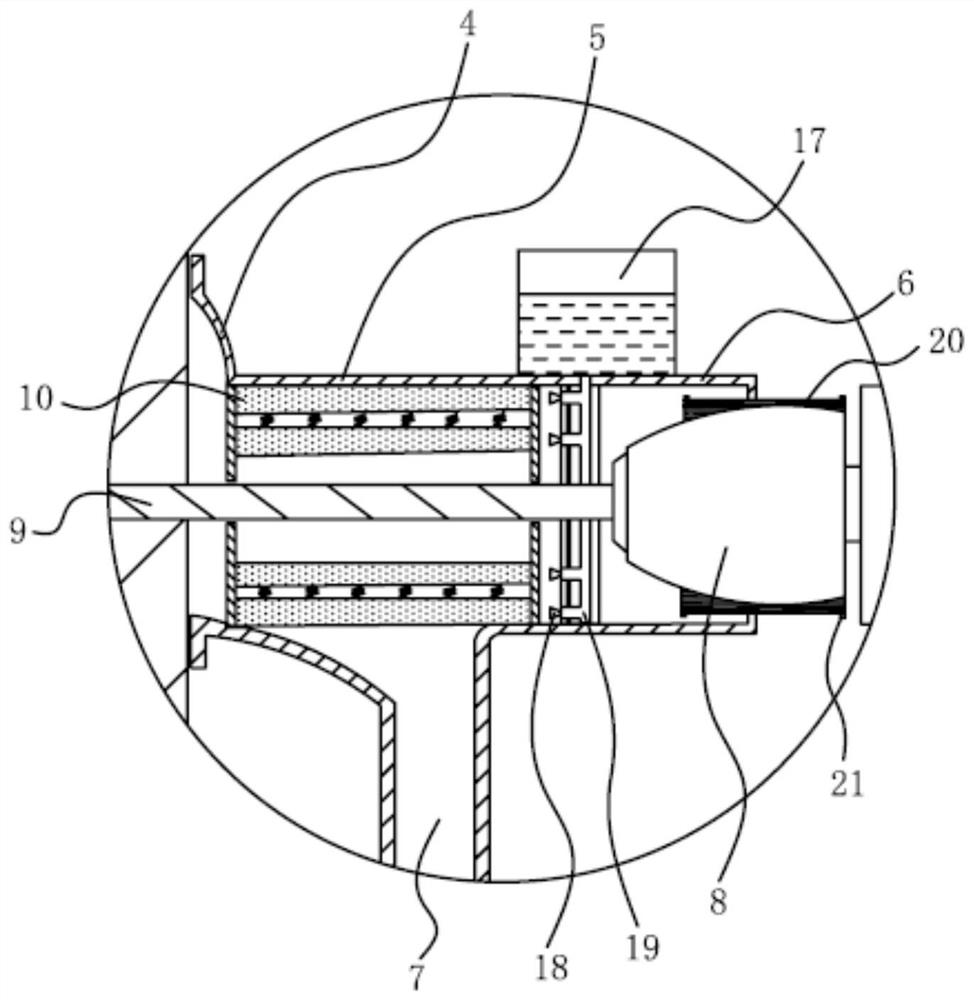

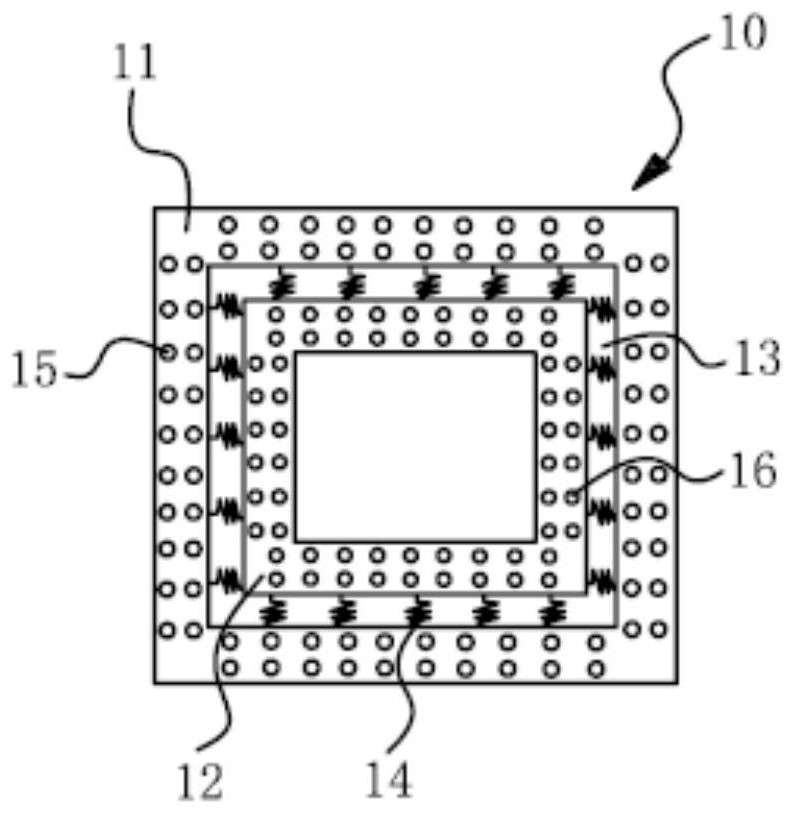

[0030] Such as figure 1 , 2 As shown in .3, a noise-reducing and dust-removing electric drill with a debris collection structure includes an electric drill body 1, and the front end of the electric drill body 1 is provided with debris for collecting falling debris when the wall 2 is punched. The collection structure 3, the debris collection structure includes a front end 4 attached to the wall surface, a middle end 5 with a cavity fixedly connected to the front end 4, a rear end 6 fixedly connected to the middle end 5, and The storage chamber 7 for collecting wall debris is arranged below the middle end 5, the rear end 6 is slidably connected with the electric drill chuck 8, and the cavity of the middle end 5 is provided with an electric drill bit 9 The noise reduction assembly 10 that buffers and weakens the noise generated when colliding with the wall, the noise reduction assembly 10 includes an outer sound-absorbing layer 11 fixedly connected to the inner surface of the mi...

Embodiment 2

[0038] Such as Figure 4 As shown, the similarities with Embodiment 1 will not be repeated, the difference is that in this embodiment, the storage chamber 7 includes an upper end portion 24, and a lower end portion 25 detachably connected to the upper end portion 24, and the upper end portion 24 passes through The connecting piece 26 is fixedly connected with the lower end portion 25 . The storage chamber 7 is divided into two parts, so that the sewage or debris in the storage chamber 7 can be cleaned up for later use. Wherein, the connecting piece 26 includes a threaded rod with a plug at one end, and a nut adapted to the threaded rod. When disassembling and using, the nut is removed from the threaded rod, then the lower end 25 is separated from the upper end 24, and then the lower end 25 is cleaned.

Embodiment 3

[0040] Such as Figure 5 As shown, the similarities with Embodiment 2 will not be described in detail. The difference is that in this embodiment, a dust reduction nozzle 23 for dust reduction is also provided inside the front end 4, and a dust reduction electromagnetic for controlling the water output of the dust reduction nozzle. The valve is not shown in the accompanying drawings, and the dust suppression electromagnetic valve adopts the existing technology, which can realize opening and closing and water volume adjustment. The control system also includes a dust concentration sensor for detecting the dust concentration in the front end of the electric drill. When the dust concentration sensor detects the dust concentration in the front end, the detection signal is sent to the controller, and the controller sends a signal to control the water output of the dust suppression solenoid valve. To the dust suppression solenoid valve. Wherein, the dust concentration sensor can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com