Crushing and sorting device for integrated circuit board

A technology of integrated circuit board and sorting device, which is applied in the fields of magnetic separation, solid separation, grain processing, etc., can solve the problems of poor sorting effect and doping of circuit board sorting and recycling materials, and achieves rapid material sorting and sorting effect. No doping, good effect of material distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

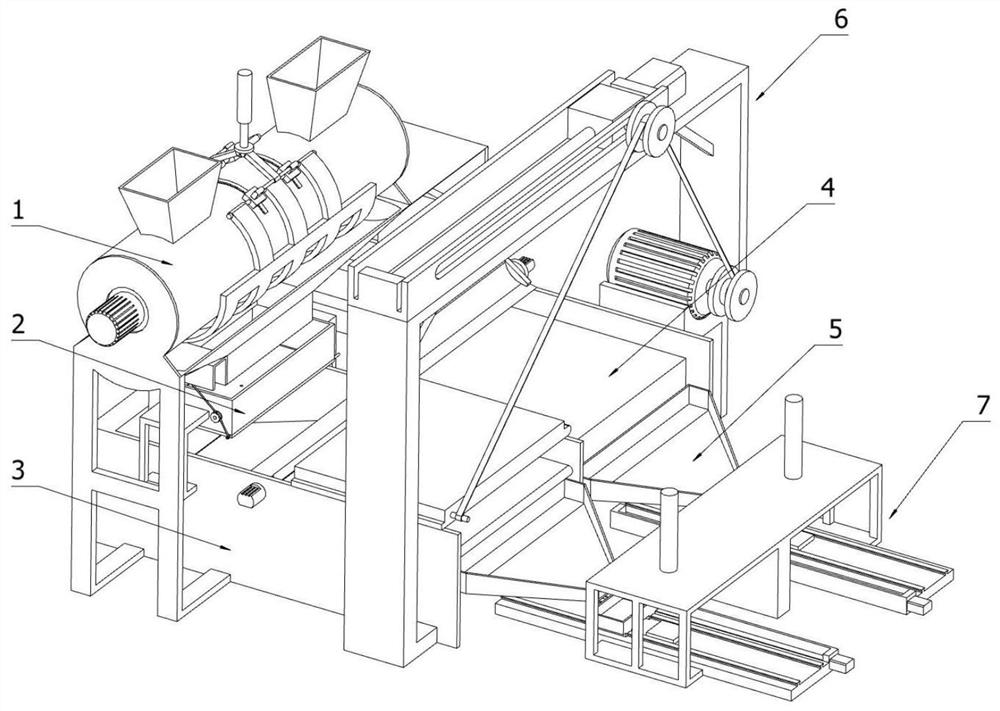

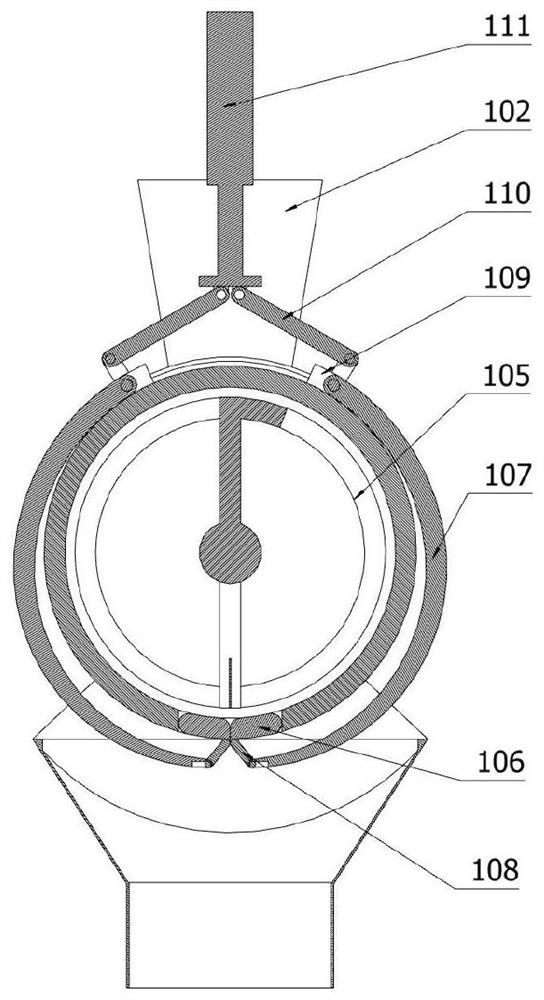

[0069] Such as figure 1 As shown, what the present invention provides is a crushing and sorting device for integrated circuit boards, comprising: a rolling mechanism 1, a vibrating mechanism 2, a conveyor belt 3, a fixed table 4, a turning mechanism 6 and a scraper 8, a rolling mechanism Mechanism 1 has a rolling drum 101, a drum 105 and an opening and closing plate 106. The drum 105 is installed in the rolling drum 101 for rolling and stirring the crushed material; the opening and closing plate 106 is arranged at the bottom of the rolling drum 101; The bottom of the material mechanism 1, the vibration mechanism 2 has a vibration frame 201, a grid plate 202 and a percussion stick 203, the vibration frame 201 is located under the rolling drum 101; the grid plate 202 is arranged at the bottom of the vibration frame 201, and the grid plate The rear end of 202 is flexibly connected with the vibrating frame 201; the knocking stick 203 is positioned at the bottom of the grid plate 2...

Embodiment 2

[0080] Same as Embodiment 1, such as Figure 9 As shown, the front of the conveyor belt 3 is also provided with a compression mechanism 7. The compression mechanism includes a track seat 701, a material delivery frame 702, a third fixed frame 705 and a bump 704. The track seat 701 is located between the conveyor belt 3 and the fixed table 4. The front side; the material transport frame 702 is arranged on the track seat 701, and a second lead screw motor 703 is provided on one side of the track seat 701, and the second lead screw motor 703 is connected to the material transport frame 702 for driving the material transport frame 702 to move; Three fixed mounts 705 are arranged on the track seat 701, the top of the third fixed mount 705 is provided with a hydraulic cylinder 706, the bottom of the third fixed mount 705 is provided with a pressing plate 707, and the pressing plate 707 is connected to the hydraulic cylinder 706; the bump 704 is arranged on the track seat 701 and bel...

Embodiment 3

[0083] A sorting method of a crushing and sorting device for integrated circuit boards, comprising:

[0084] Stir the crushed material, pour the crushed material from the blanking frame 102 into the rolling drum 101, and then start the drum 105 to stir the crushed material. When stirring, heat the rolling drum 101 to make the rolling drum The temperature inside 101 reaches about 20°C to keep the material dry. After the rolling is completed, the lifting cylinder 111 is started to shrink, so that the moving slide 109 moves closer, the bending rod 107 rises, and the opening and closing plate 106 is opened, so that the crushed material falls to the material guide frame 104 in;

[0085] Knock the crushed material, the crushed material falls from the material guide frame 104 into the vibrating frame 201, start the telescopic cylinder 205 to drive the percussion stick 203 to knock the bottom of the grid plate 202, so that the crushed material is hit and dispersed, and then Start the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com