Multi-disc clutch with optimised displacement friction; hybrid module, dual clutch device and drivetrain

A powertrain, dual-clutch technology, applied to multi-plate clutches with optimized moving friction; a hybrid module, which can solve problems such as high drag torque, incorrect clutch disengagement, thermal load clutch damage, etc., to reduce friction torque , the effect of saving structural space and robust support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

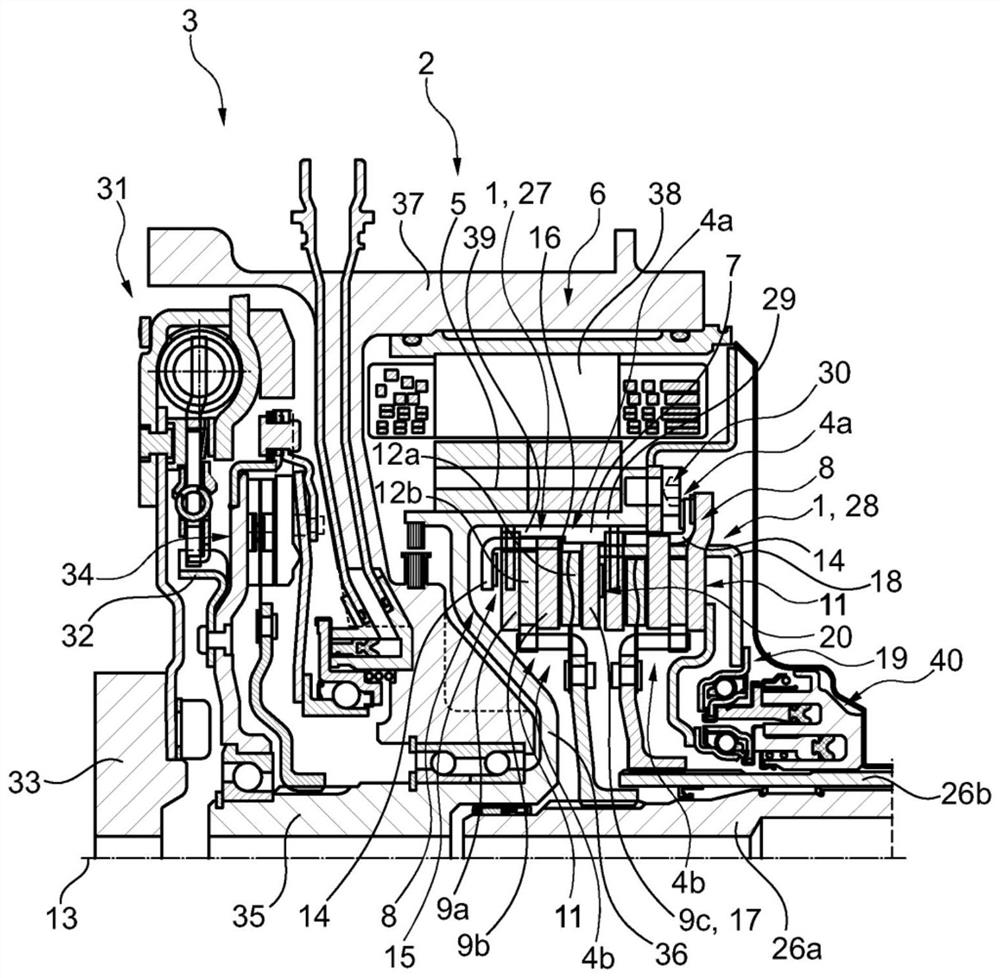

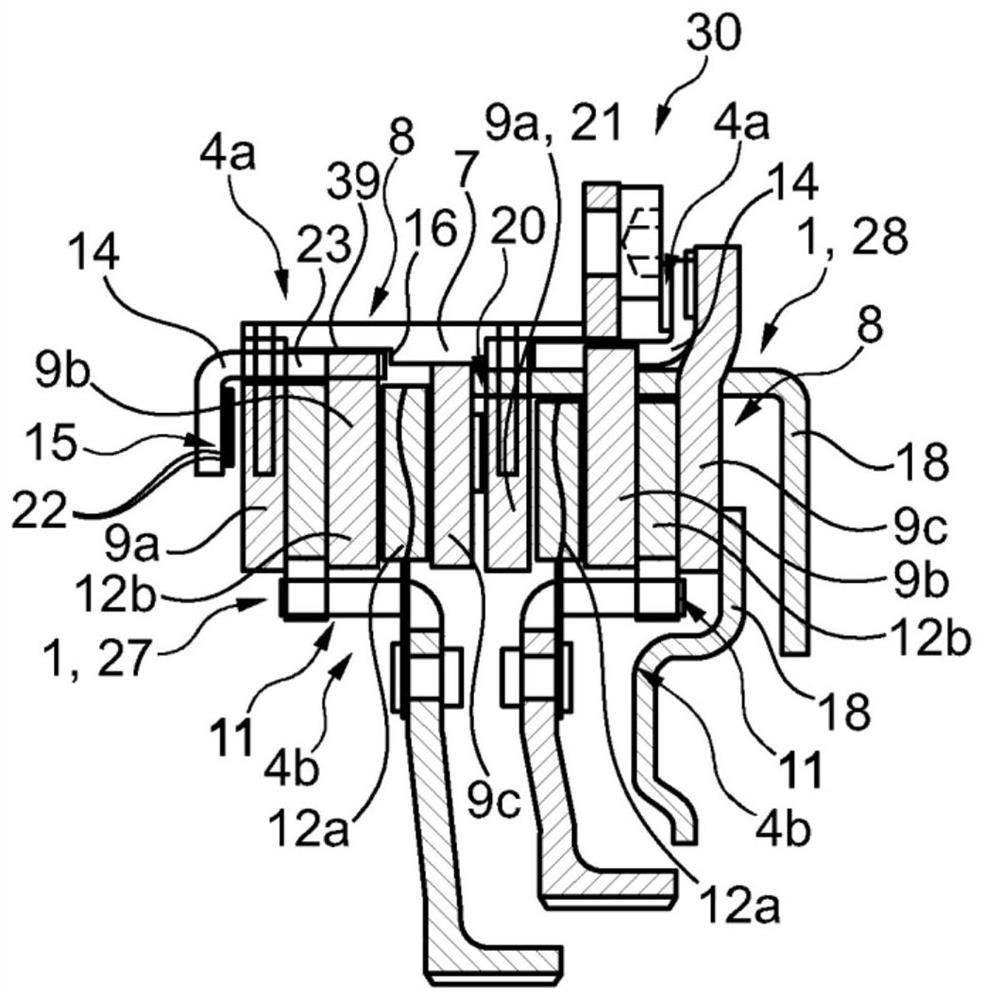

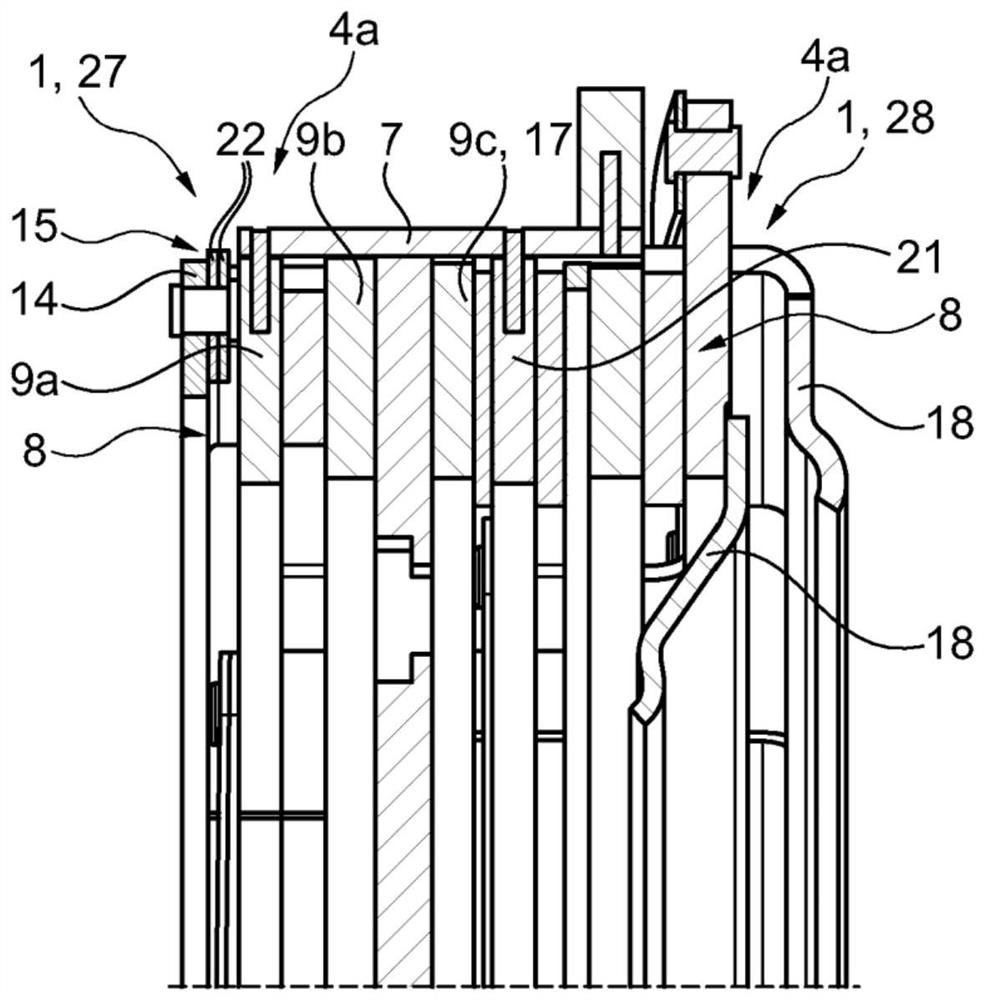

[0034] Combine Figure 1 to 6 In detail seen a first embodiment of the multi-plate clutch as a friction clutch of the present invention is implemented 1. Further aid Figure 7 to 10 Illustrate two further embodiments, however, these two further embodiments of structure and function in accordance with the principles of a multi-plate clutch of the first embodiment. For brevity, therefore only the differences between the embodiments set forth in the following embodiments.

[0035] returnfigure 1 It can be seen that the multi-plate clutch 1 according to the present invention is used in the mixing module 2 or is formed into a component of the mixing module 2. Furthermore, the mixing module 2 is used in a typical manner in the power assembly 3 of the motor vehicle. The power assembly 3 illustrates the two transmission input shafts 26a, 26b side of the transmission in this view. The transmission input shaft 26a, 26b is connected to the output side of the mixing module 2, as described in de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com