Textile air permeability detector

A gas permeability and detector technology, applied in the field of textiles, can solve problems affecting detection accuracy, detection position sealing, and air permeability detection accuracy, and achieve the effect of increasing test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

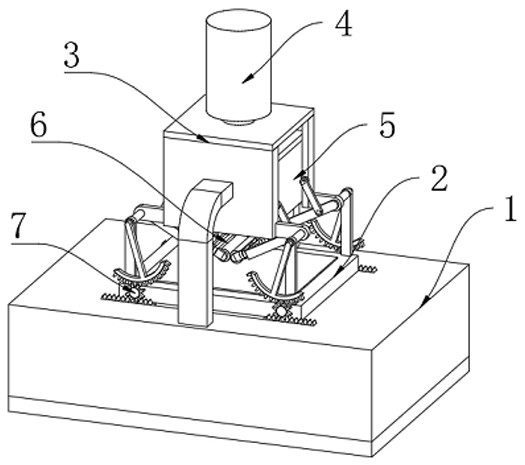

[0032] see figure 1As shown, a textile air permeability tester includes an installation base 1, a processing table 2 is fixedly connected to the middle position of the top of the installation base 1, and a ventilation slot 9 is opened in the middle position of the processing table 2, and the upper surface of the processing table 2 is opposite to The outer edge of the ventilation slot 9 is provided with a sealing groove 10, and the top of the installation base 1 is fixedly connected to the limit housing 3 relative to the upper position of the processing table 2. The top of the limit housing 3 is fixedly installed with a hydraulic cylinder 4, and the hydraulic cylinder 4 The bottom of the bottom extends to the inner cavity of the limit housing 3, and a sealing cover 5 is fixedly installed on the bottom. The sealing cover 5 is a hollow structure. The size of the outer wall of the bottom of the sealing cover 5 is the same as the inner diameter of the sealing groove 10. Spread the ...

Embodiment 2

[0034] see Figure 6 As shown, it is basically the same as Embodiment 1, furthermore, the left and right sides of the sealing cover 5 are provided with a smoothing mechanism 6, taking the right side wall smoothing mechanism 6 as an example, the smoothing mechanism 6 includes a mounting block 22 , the mounting block one 22 is provided with two groups, fixedly installed on the front and rear sides of the right side wall of the sealing cover 5 respectively; There is smoothing mechanism 6 movably connected between the inwalls of two 24, movable plate 23 is movably connected between the inwall upper side of smoothing mechanism 6 and the inwall of installation piece one 22, and the outer wall of installation piece two 24 is movably connected with rotating shaft 26, The rotating shaft 26 is located at the axial center where the mounting frame 25 is connected to the second mounting block 24 , and the rotating shaft 26 is coaxially fixedly connected with the mounting frame 25 .

[003...

Embodiment 3

[0038] see Figure 8 As shown, it is basically the same as the second embodiment, and furthermore, the inner cavity of the installation base 1 is fixedly equipped with an inflatable mechanism 8, and the inflatable mechanism 8 includes a gas storage shell one 37, and the middle position of the inner cavity of the gas storage shell one 37 is An air bag 40 is fixedly installed, and the embedded side of the air bag 40 is provided with a spring 2 41 horizontally. The top of the air bag 40 is provided with a one-way valve connected from the inside to the outside, and the bottom of the air bag 40 is provided with a one-way valve connected from the outside to the inside. The inner cavity of housing one 37 is provided with pressing plate 38 relative to the left and right sides of airbag 40, and the side of pressing plate 38 away from airbag 40 is fixedly connected with push rod one 39, and the side of push rod one 39 away from pressing plate 38 is fixedly connected with push plate 36 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com