Compact and stable quick pipeline connector

A quick connection and connector technology, applied in the direction of couplings, mechanical equipment, etc., can solve the problems of unsuitable for large-scale processing and production, the complexity of quick pipeline connectors, and the difficulty of assembly operations, so as to avoid the failure of locking tubes, Solve the effect of difficult disassembly and easy identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

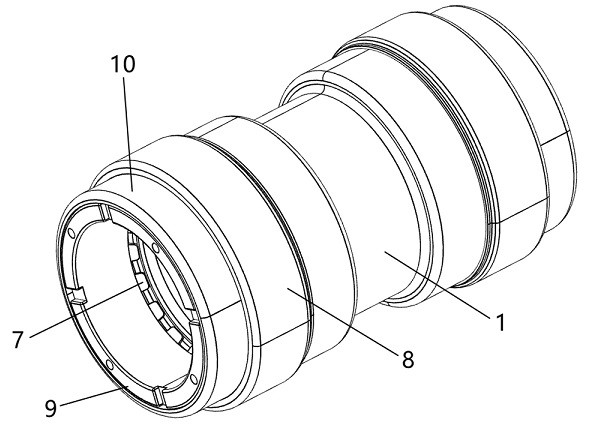

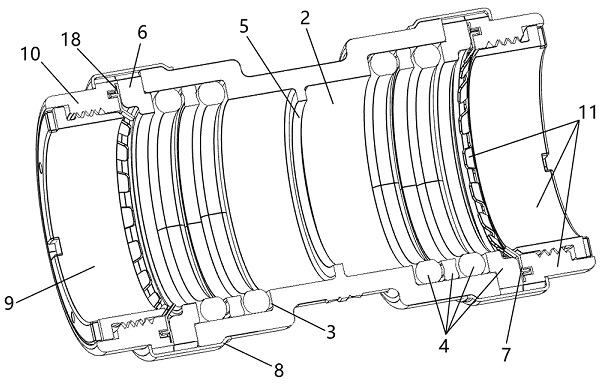

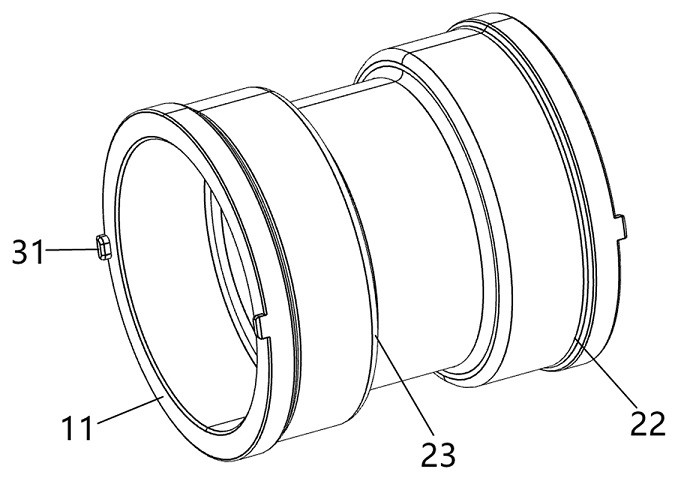

[0037] Such as Figure 1~11 As shown in combination, a compact and stable quick-connect pipe connector includes a connector housing 1, one or more quick-connect ports 2 are arranged on the connector housing 1, and the inner wall of each quick-connect port 2 There is a connection groove 3 connected to its end surface, the sealing assembly 4 is placed in the connection groove 3, the lock tube assembly is set on the quick connection port 2, and the inner wall of the quick connection port 2 is provided with a The pipe positioning step 5 that limits the insertion depth of the external pipe, the pipe positioning step 5 is located inside the connecting groove 3;

[0038] The sealing assembly 4 includes a sealing ring 32, a spacer ring 33 and an inner ring cover 6, at least two sealing rings 32 are placed in the connecting groove 3, and the spacer ring 33 is arranged between two adjacent sealing rings 32 Between, the inner ring cover 6 fits on the connector housing 1 located outside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com