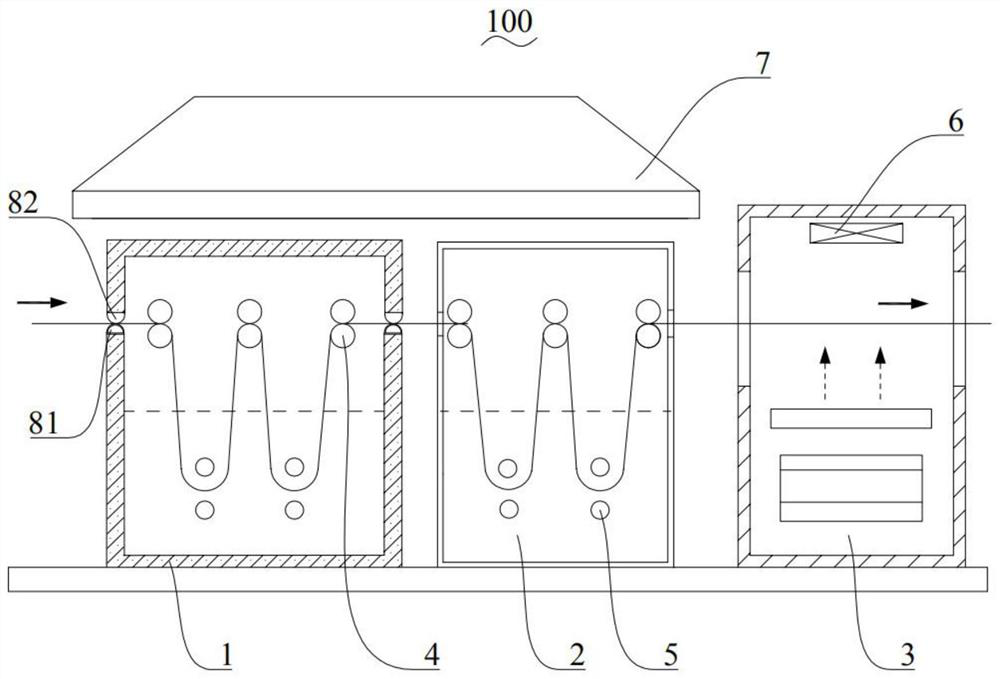

Continuous liquid ammonia finishing and processing device and method for improving hydrophilicity of cotton non-woven fabric

A liquid ammonia finishing and processing device technology, which is applied in the processing of textile materials, the configuration of equipment for processing textile materials, and the processing of liquid/gas/steam textile materials, etc. problem, to achieve the effect of promoting the loosening of the fiber structure, increasing the hydrophilicity and smoothness, and feeling soft and plump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

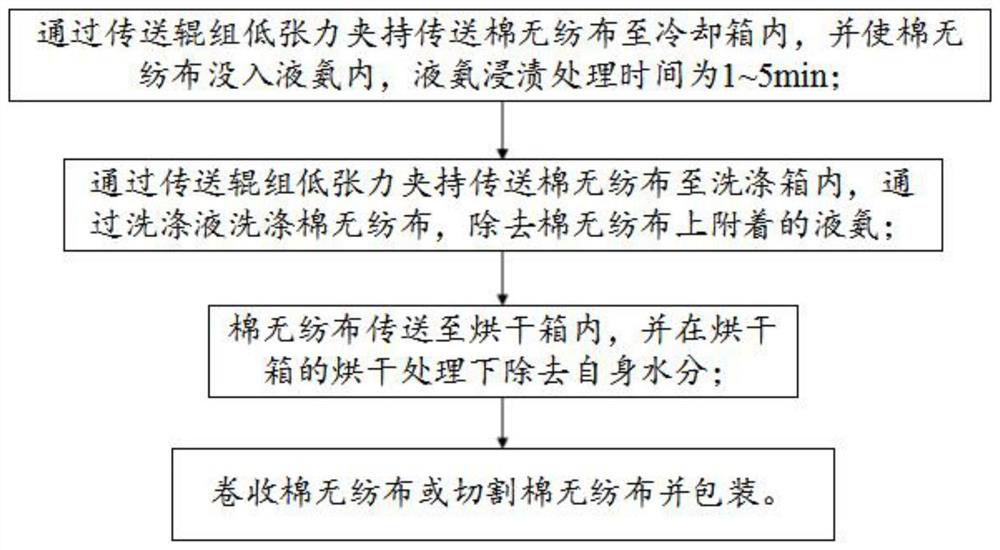

[0047] Embodiment 1 provides a kind of continuous liquid ammonia finishing processing method that improves the hydrophilicity of cotton non-woven fabrics and comprises the following steps:

[0048] S1: The cotton non-woven fabric is clamped and conveyed to the cooling box 1 by the conveying roller group 4 with low tension, and the cotton non-woven fabric is submerged in the liquid ammonia. The impregnation treatment time of the cotton non-woven fabric is 1min. The structure is loose under the impregnation of liquid ammonia, and the loose cotton non-woven fabric is not easy to be stretched or even broken under low tension;

[0049] S2: The cotton non-woven fabric is clamped and conveyed to the washing box 2 by the transmission roller group 4 with low tension. The temperature of the washing liquid is 80°C. The cotton non-woven fabric is washed by the washing liquid for 2 minutes, and the cotton non-woven fabric is removed. Attached liquid ammonia, the fiber structure of the cott...

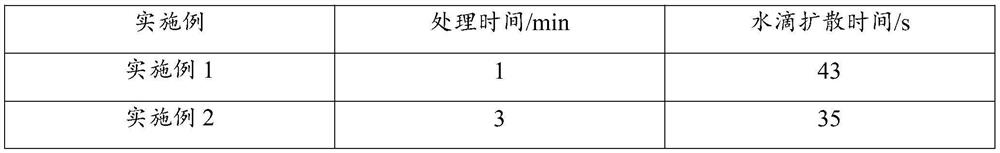

Embodiment 2-3

[0053] The difference between Embodiment 2-3 and Embodiment 1 is only that the time of immersion treatment in liquid ammonia in step S1 is different, and other conditions are basically the same, which will not be repeated here. The processing time and test result record of embodiment 2-3 are as shown in table 1.

Embodiment 4-6

[0064] The difference between Examples 4-6 and Example 1 is only that the temperature and washing time of the washing liquid of the cotton non-woven fabric are different in step S1, and other conditions are basically the same, and will not be repeated here. The details are shown in Table 2.

[0065] Table 2 embodiment 4-6 process parameter and performance test result

[0066] Example Washing liquid temperature / ℃ Washing time / min Water droplet diffusion time / s Example 4 60 3 39 Example 5 80 4 35 Example 6 100 5 29

[0067] From the experimental results of Examples 4-6, it can be seen that the cotton non-woven fabric treated with loose-type low-tension liquid ammonia, when the washing temperature is 60-100°C and the washing time is 3-5min, the As the washing time increases, the hydrophilicity of cotton non-woven fabrics also increases.

[0068] In summary, the present invention adopts the continuous loose-type low-tension treatment p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com