Broadband optical absorbent and coating preparation method

An optical absorption, wide-band technology, applied in the field of materials, can solve problems such as performance and range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

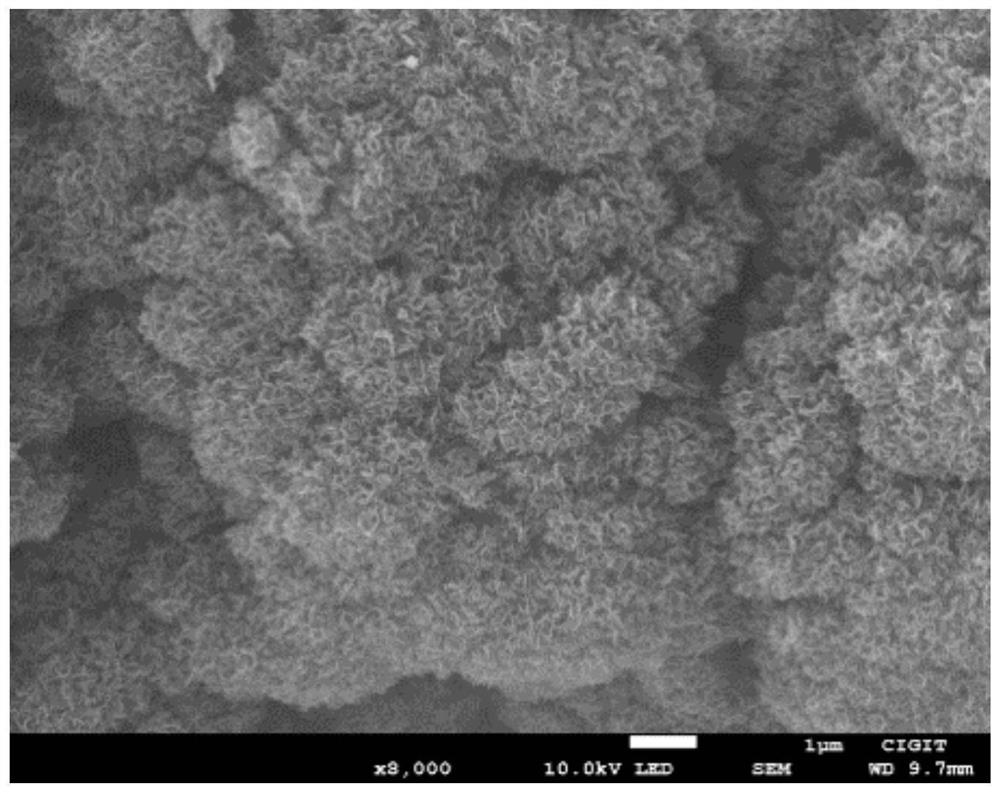

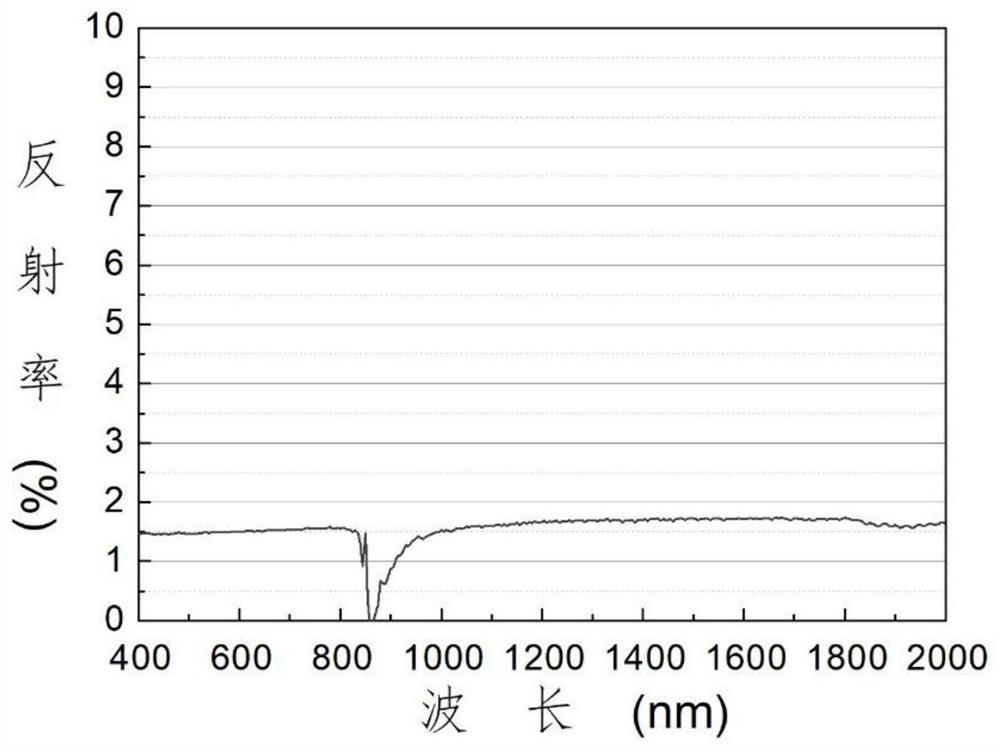

[0031]The object of the present invention is to provide a kind of light-absorbing agent and the preparation method of coating thereof with broadband absorption characteristic from visible light to infrared band, it is characterized in that, comprises the following steps: 1) take by weighing 4mmol cobalt chloride and 48mmol hexamethylene The base tetramine was dissolved in 800ml of mixed solvent composed of deionized water and absolute ethanol, and the volume ratio of deionized water and absolute ethanol was 9:1; stirred by a magnetic stirrer for 15min until the precursor powder was completely dissolved, and then transferred to In the three-necked flask, the mixture was heated to 90°C under magnetic stirring, and kept at this temperature for 1 hour;

[0032] 2) The precipitate obtained in step 1) was collected by vacuum filtration, washed alternately with deionized water and absolute ethanol three times each, and dried in an oven at 60° C. for 5 hours to obtain nano-sized cobalt...

Embodiment 2

[0040] 1) Weigh 4mmol of nickel chloride and 48mmol of hexamethylenetetramine and dissolve in 800ml of mixed solvent composed of deionized water and absolute ethanol, the volume ratio of deionized water and absolute ethanol is 9:1; Stir for 15 minutes until the precursor powder is completely dissolved, then transfer it to a three-necked flask, heat the mixture to 100°C under magnetic stirring, and keep it at this temperature for 1 hour;

[0041] 2) The precipitate obtained in step 1) was collected by vacuum filtration, washed alternately with deionized water and absolute ethanol 3 times each, and dried in an oven at 60° C. for 5 hours to obtain nano-sized nickel hydroxide powder;

[0042] 3) Weigh 10 g of nickel hydroxide obtained in step 2) into a quartz boat, and vacuumize for 10 minutes to maintain an oxygen-free environment in the quartz tube. Then pass in the mixed gas of argon and hydrogen, the flow rate of argon gas is controlled at 100 sccm, the flow rate of hydrogen g...

Embodiment 3

[0049] 1) Weigh 4mmol ferric chloride and 48mmol hexamethylenetetramine and dissolve in 800ml of mixed solvent composed of deionized water and absolute ethanol, the volume ratio of deionized water and absolute ethanol is 9:1; Stir for 15 minutes until the precursor powder is completely dissolved, then transfer it to a three-necked flask, heat the mixture to 110°C under magnetic stirring, and keep it at this temperature for 1 hour;

[0050] 2) The precipitate obtained in step 1) was collected by vacuum filtration, washed alternately with deionized water and absolute ethanol three times each, and dried in an oven at 60° C. for 5 hours to obtain nanoscale iron hydroxide powder;

[0051] 3) Weigh 10 g of ferric hydroxide obtained in step 2) and put it into a quartz boat, and vacuumize for 10 minutes to maintain an oxygen-free environment in the quartz tube. Then pass in the mixed gas of argon and hydrogen, the flow rate of argon gas is controlled at 100 sccm, the flow rate of hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com