A kind of preparation method of inorganic high emissivity coating containing graphene oxide

A high-emissivity, graphene technology, applied in the field of preparation of inorganic high-emissivity coatings, can solve the problems of low emissivity of inorganic high-emissivity coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

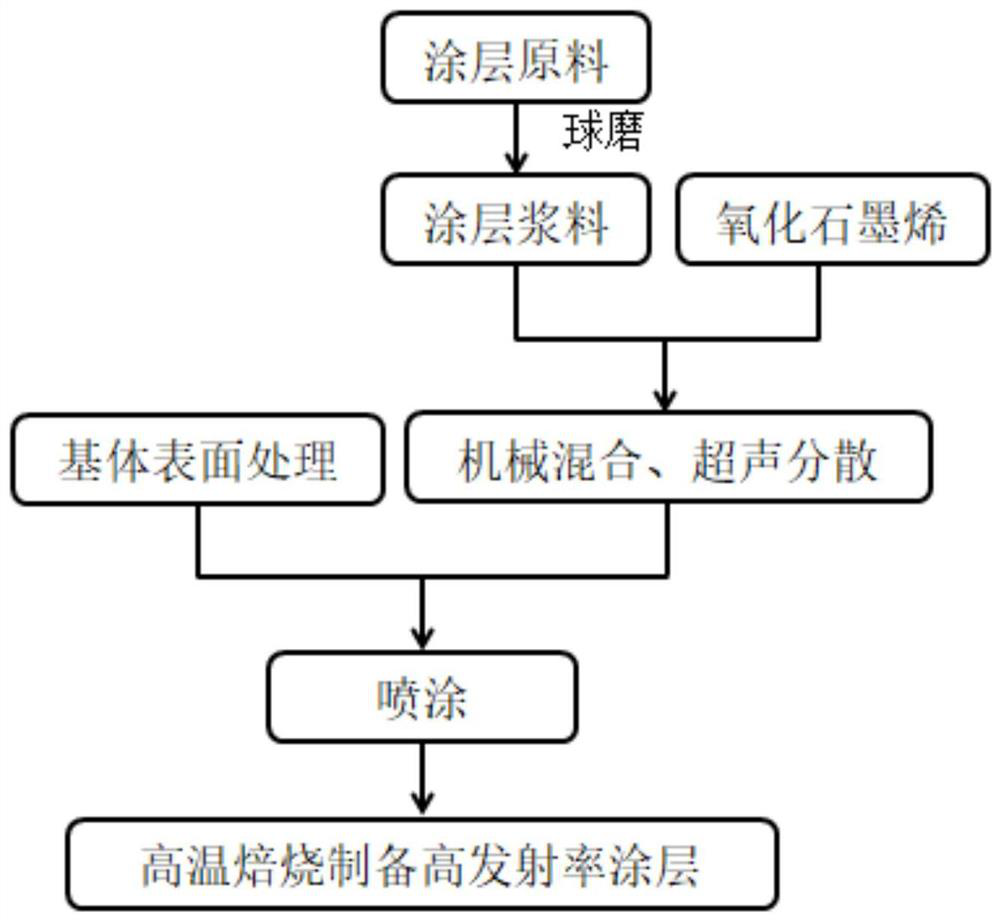

Method used

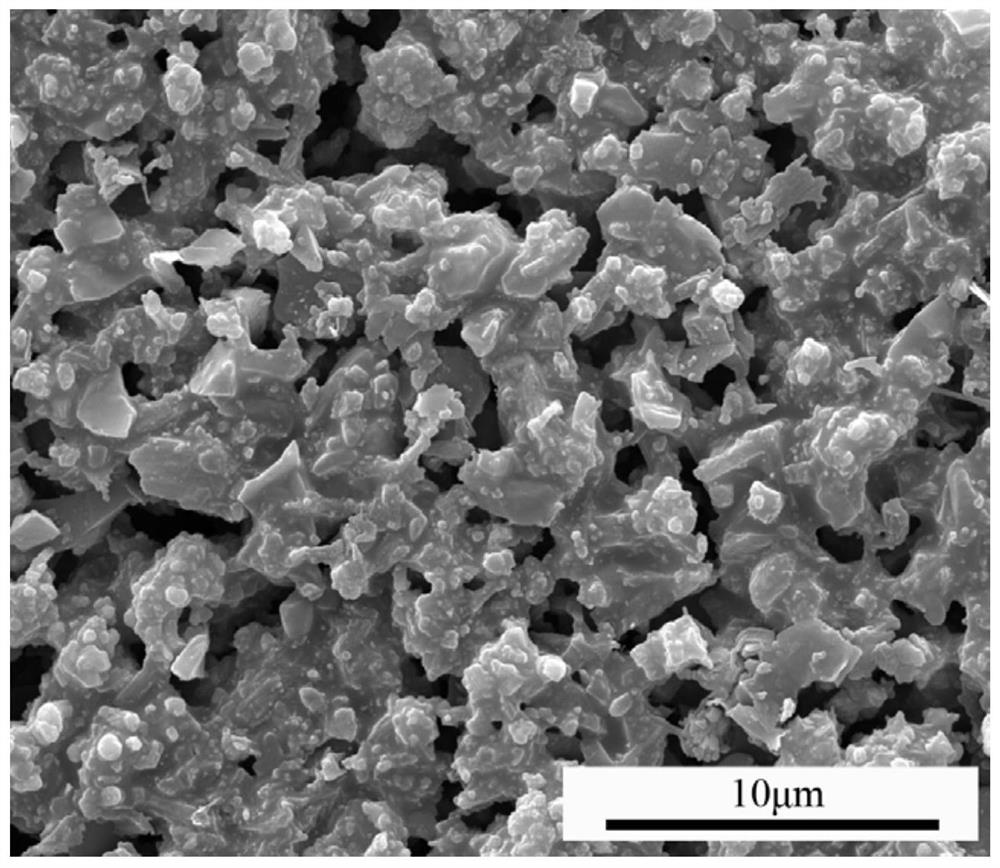

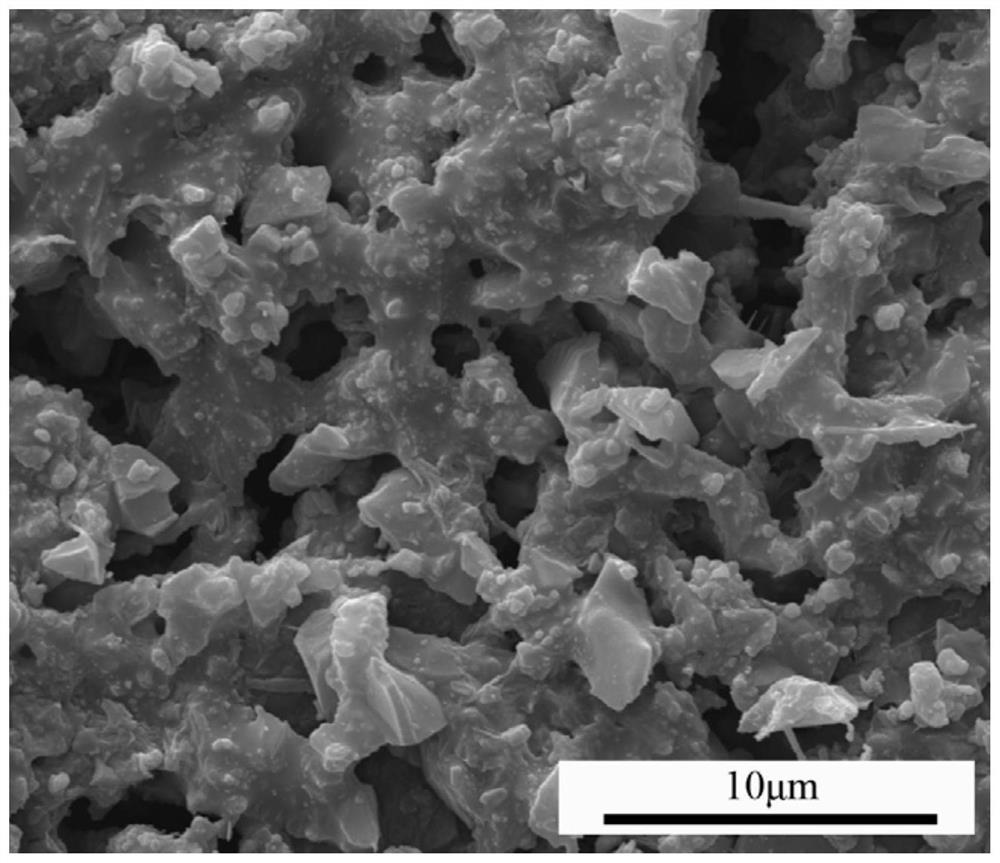

Image

Examples

specific Embodiment approach 1

[0032] Specific embodiment one: present embodiment is a kind of preparation method of the inorganic high emissivity coating containing graphene oxide, specifically is to carry out as follows according to the following steps:

[0033] 1. Ball milling: Mg 2 B 2 o 5 Whisker powder and SiO 2 The powders were wet-mixed and ball-milled at a speed of 320 rpm to 350 rpm for 8 hours to 9 hours, and the two slurries after ball milling were filtered through a 100-mesh sampling sieve to separate the balls. Dry each slurry in a drying oven at 60°C to 80°C to obtain two cakes, grind the two cakes respectively and put them in a drying oven for 1h to 1.5h to obtain ball-milled SiO 2 Mg after powder and ball milling 2 B 2 o 5 Whisker powder;

[0034] Ball milled SiO 2 In the case of powder, it is SiO according to the mass ratio 2 Powder: Grinding Ball: Water = 1:2:1;

[0035] Milled Mg 2 B 2 o 5 Whisker powder, according to the mass ratio of Mg 2 B2 o 5 Whisker powder: grinding ...

specific Embodiment approach 2

[0040] Specific embodiment two: the difference between this embodiment and specific embodiment one is: ball milling SiO in step one 2 The powder balls are zirconia. Others are the same as the first embodiment.

specific Embodiment approach 3

[0041] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: ball milling Mg in step one 2 B 2 o 5 The grinding ball of the whisker powder is zirconia. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com