Preparation of glycolipid type ionic liquid and application of glycolipid type ionic liquid in glycolipid separation process

A technology of ionic liquid and glycolipid, which is applied in the field of preparation of glycolipid-type ionic liquid, can solve the problems of complicated separation process, high production cost of rhamnolipid, and difficult separation of glycolipid fermentation liquid, etc. The process is green and environmentally friendly, and the structure is novel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0055] The preparation process of di-n-butylamine rhamnolipid ionic liquid in this embodiment comprises the following steps:

[0056](1) Use a 20nm ceramic membrane to filter and separate 10kg of rhamnolipid fermentation broth to obtain 7.5kg of sterilized filtrate, add 7.5g of concentrated sulfuric acid to the filtrate, stir for 1 hour and precipitate out after stirring for 2 hours. Filter with a 20 μm nylon filter cloth, and collect a total of 503 g of solids.

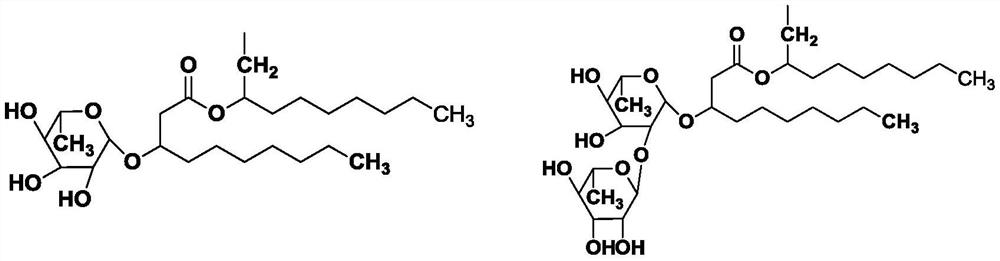

[0057] (2) Mix the obtained solid with an equal mass of di-n-butylamine and transfer it to a three-necked flask, heat it to 50° C. for 1 hour under stirring, then cool it down to room temperature, add 200 g of dichloromethane, and transfer it to a separatory funnel after fully mixing. Set phase separation, separate the upper layer, a total of 857g, is a glycolipid-type ionic liquid. The structure is as follows

[0058]

Embodiment 2

[0060] The preparation process of di-n-octylamine glycolipid type ionic liquid in this embodiment comprises the following steps:

[0061] (1) Use a 500nm ceramic membrane to filter and separate 5kg of rhamnolipid fermentation liquid to obtain 4.5kg of sterilized filtrate, add 45g of concentrated sulfuric acid to the filtrate, stir for 3 hours and precipitate out after stirring for 1.5 hours. Filtration was carried out with a 50 μm polypropylene filter cloth, and a total of 305 g of solids were collected.

[0062] (2) Mix the obtained solid with an equal mass of di-n-octylamine and transfer it to a three-necked flask, heat it to 80° C. for 2 hours under stirring, then cool it down to room temperature, add 203 g of dichloromethane, and transfer it to a separatory funnel after fully mixing. Set phase separation, separate the upper layer, a total of 522g, is a glycolipid-type ionic liquid. The structure is as follows

[0063]

Embodiment 3

[0065] The preparation process of dicyclohexylamine glycolipid type ionic liquid in this embodiment comprises the following steps:

[0066] (1) Use a 200nm ceramic membrane to filter and separate 3kg of rhamnolipid fermentation liquid to obtain 2.8kg of sterilized filtrate, add 14g of concentrated sulfuric acid to the filtrate, stir for 2 hours and precipitate out after stirring for 1 hour. Filtration was carried out with a 30 μm polydimethylsulfoxide filter cloth, and a total of 209 g of solids were collected.

[0067] (2) Mix the obtained solid with an equal mass of dicyclohexylamine and transfer it to a three-necked flask, heat it to 60°C under stirring and keep it for 1.5 hours, then cool it down to room temperature, add 105g of dichloromethane, and transfer it to a separatory funnel after fully mixing. Set phase separation, separate the upper layer, a total of 389g, is a glycolipid-type ionic liquid. The structure is as follows

[0068]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com