Compound, composite composed of compound, application and display panel

A technology of compounds and compositions, which is applied in the field of compounds and their compounds, applications, and display panels, can solve the problems of decreased flatness of inorganic films, increased water vapor transmission rate, and adverse effects on devices, so as to reduce the quantity and reduce the The effect of miscellaneous gas emission and excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

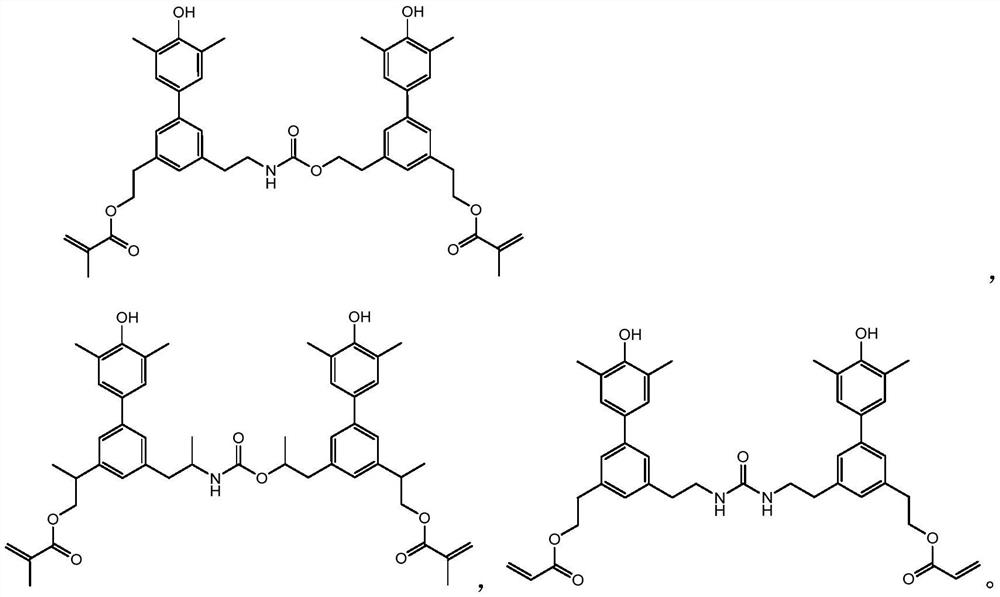

Embodiment 1

[0054] 2-(4'-hydroxy-5-(2-isocyanato)-3',5'-dimethyl-[1,1'-biphenyl]-3-yl)ethyl methacrylate (compound a )80g and 2-(4'-hydroxy-5-(2-hydroxyethyl)-3',5'-dimethyl-[1,1'-biphenyl]-3-yl)ethyl methacrylate (Compound b) 81.5 g was added and dissolved in 300 mL of toluene, 0.6 g of dibutyltin dilaurate was added, and it stirred while heating at 60 degreeC for 4 hours. The temperature was cooled to room temperature, and the solvent was removed using a reduced-pressure distiller to obtain 98.6 g of Compound 1.

[0055]

[0056] The compound 1 was detected and analyzed, and the specific results were as follows:

[0057] HPLC purity: greater than 90%.

[0058] Mass Spectrum: Calculated 733.90; Found 732.84.

[0059] Elemental analysis:

[0060] Calculated values: C: 73.65%; H: 7.00%; N: 1.91%; O: 17.44%.

[0061] The test values are: C: 74.15%; H: 7.48%; N: 1.52%; O: 16.85%.

Embodiment 2

[0063] 2-(4'-hydroxy-5-(2-isocyanatopropyl)-3',5'-dimethyl-[1,1'-biphenyl]-3-yl)propyl methacrylate (compound c) 85.5 g and 2-(4'-hydroxy-5-(2-hydroxypropyl)-3',5'-dimethyl-[1,1'-biphenyl]-3-yl)methacrylic acid After adding 88 g of propyl ester (compound d) to 300 mL of toluene and dissolving it, 0.6 g of dibutyltin dilaurate was added, followed by stirring at 60° C. for 4 hours. The temperature was cooled to room temperature, and the solvent was removed using a reduced-pressure distiller to obtain 101 g of Compound 2.

[0064]

[0065] HPLC purity: greater than 90%.

[0066] Mass Spectrum: Calculated 790.01; Found 789.19.

[0067] Elemental analysis:

[0068] Calculated values: C: 74.50%; H: 7.53%; N: 1.77%; O: 16.20%.

[0069] The test values are: C: 75.02%; H: 7.61%; N: 1.58%; O: 15.79%.

Embodiment 3

[0071] 2-(4'-hydroxy-5-(2-isocyanato)-3',5'-dimethyl-[1,1'-biphenyl]-3-yl)ethyl acrylate (compound e) 76.7 g and ethyl 2-(5-(2-aminoethyl)-4'-hydroxy-3',5'-dimethyl-[1,1'-biphenyl]-3-yl)acrylate (compound f ) 78.1 g was dissolved in 300 mL of toluene, and 0.6 g of dibutyltin dilaurate was added, followed by stirring at 60° C. for 4 hours. The temperature was cooled to room temperature, and the solvent was removed using a reduced-pressure distiller to obtain 72.5 g of Compound 3.

[0072]

[0073] HPLC purity: greater than 90%.

[0074] Mass Spectrum: Calculated 704.86; Found 703.91.

[0075] Elemental analysis:

[0076] Calculated values: C: 73.27%; H: 6.86%; N: 3.97%; O: 15.89%.

[0077] The test values are: C: 73.85%; H: 7.02%; N: 3.55%; O: 15.58%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com