Quartz sand alkaline leaching purification process

The technology of quartz sand and sand alkali is applied in the field of quartz sand alkali leaching purification technology, which can solve the problems of high price, high risk and high production cost, and achieve the effects of low production cost, low risk and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

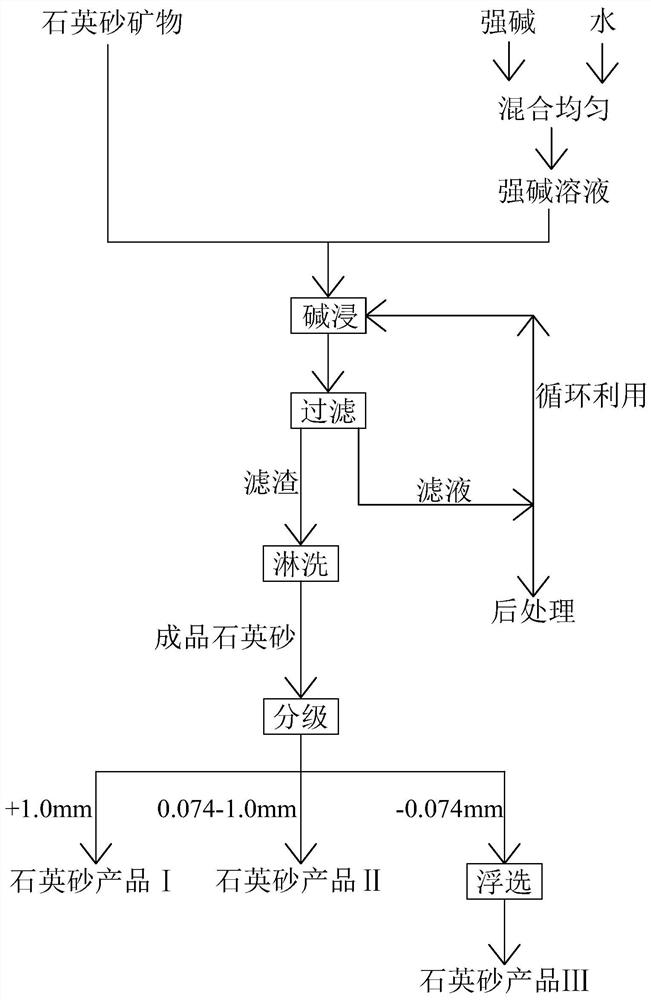

[0059] refer to figure 1 , a quartz sand alkali leaching purification process, comprising the following steps:

[0060] Alkaline leaching: stirring and mixing 1000kg of quartz sand mineral with a dry weight of 1000kg and 1000kg of sodium hydroxide solution with a concentration of 20%, heating the temperature to 90°C, and stirring and reacting at 90°C for 3 hours to obtain a solid-liquid mixture, wherein The yield of particles with a size of less than 0.074 mm in the quartz sand mineral was 8.87%.

[0061] Filtration: centrifugal filtration of the solid-liquid mixture using filtration equipment to obtain filter residues.

[0062] Rinse: the filter residue is rinsed with water until the pH value of the rinse water is 7, and the finished quartz sand is obtained.

[0063] Classification: The leached finished quartz sand is screened into two specifications: particle size 1.0mm, the quartz sand >1.0mm is the quartz sand product I, and the 0.074-1.0mm quartz sand is the quartz sand...

Embodiment 2

[0066] A quartz sand alkali leaching purification process, comprising the following steps:

[0067] Alkaline leaching: stirring and mixing 1000kg of quartz sand mineral with a dry weight of 1000kg and 1500kg of sodium hydroxide solution with a concentration of 30%, heating up to 100°C, and stirring and reacting at 100°C for 3 hours to obtain a solid-liquid mixture, wherein The yield of particles with a size of less than 0.074 mm in the quartz sand mineral was 9.89%.

[0068] Filtration: centrifugal filtration of the solid-liquid mixture using filtration equipment to obtain filter residues.

[0069] Rinse: the filter residue is rinsed with water until the pH value of the rinse water is 8, and the finished quartz sand is obtained.

[0070] Classification: The leached finished quartz sand is screened into two specifications: particle size 1.0mm, the quartz sand >1.0mm is the quartz sand product I, and the 0.074-1.0mm quartz sand is the quartz sand product II.

[0071] Flotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com