Lifting steering device for standardizing iron tower assembling and erection

A technology for tower assembly and steering device, applied in the direction of hoisting device, tower, building type, etc., can solve problems such as hidden dangers, tower material wear, plating damage safety, etc., to eliminate damage, avoid potential safety hazards, and eliminate potential safety hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

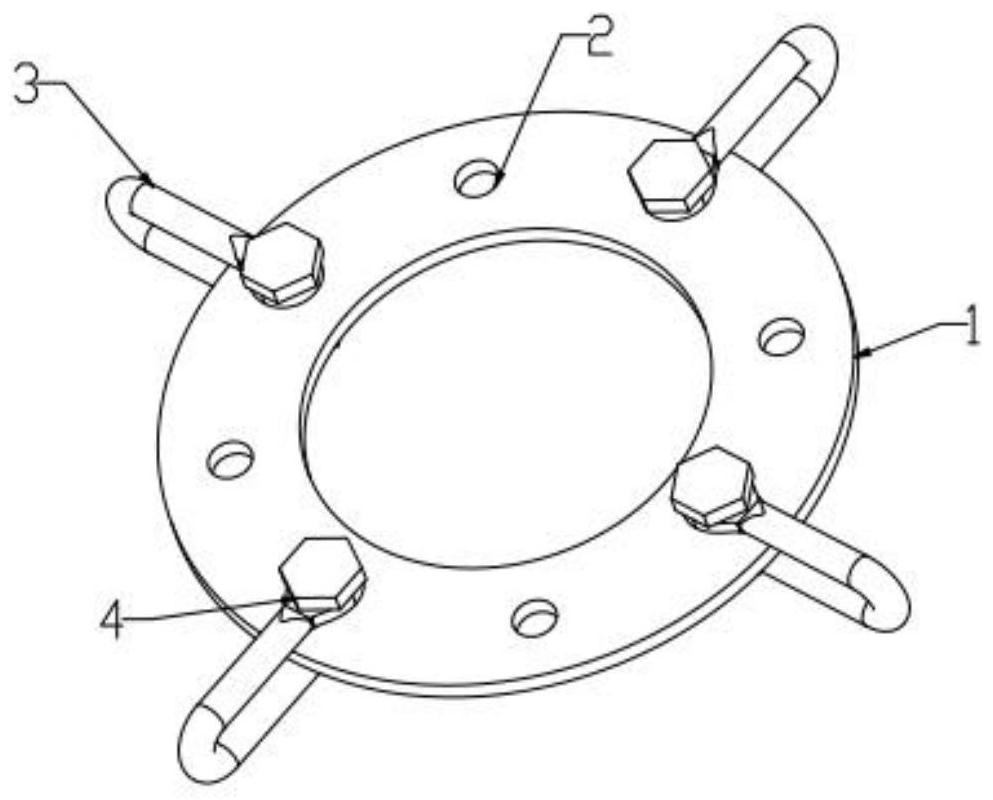

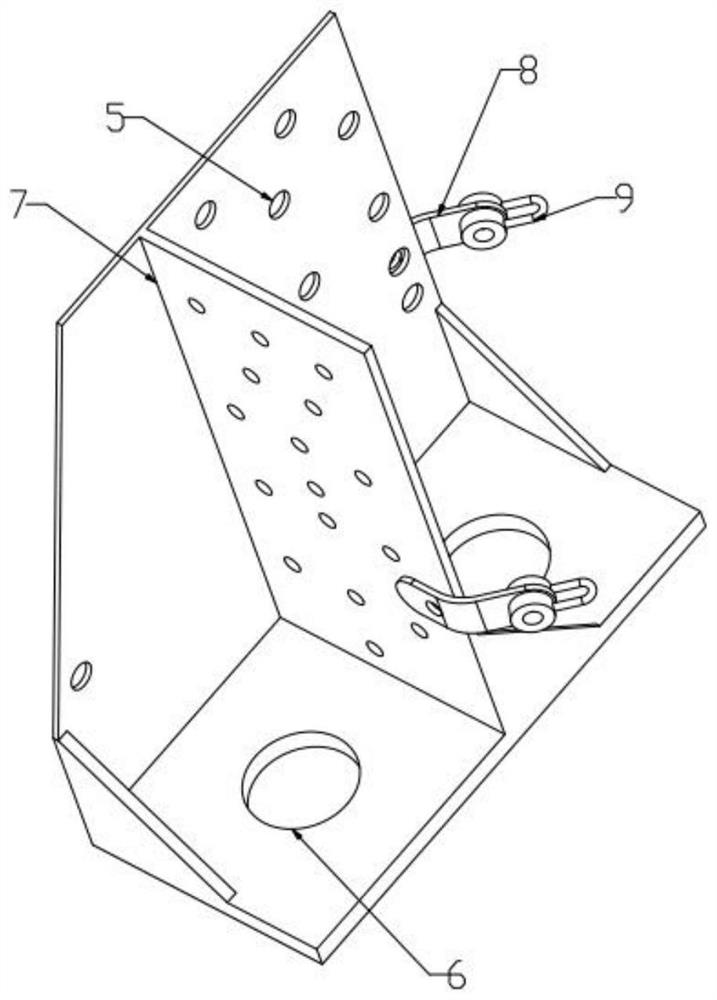

[0028] In this embodiment, a standard hoisting and steering device for iron tower assembly includes a tension steering flange 1, a tower foot plate 7, and a fire-curved tension steering plate 8. Both sides of the fire-curved tension steering plate 8 are provided with There is a connection hole, one end of the fire-curved tension steering plate 8 is directly connected to the construction hole 5 provided on the tower foot plate 7, and the tension steering flange 1 is provided with an eye hole 2, and the eye hole 2 is passed through the bolt 4 A first U-shaped ring 3 is connected, and a support rope is hinged between the first U-shaped ring 3 and the fire-curved tension steering plate 8. The diameter of the eye hole 2 is φ32, and the tower foot plate 7 passes through The bolt hole 6 is connected with the prefabricated mechanism on the ground; the contact point of the tension steering plate 8 adopts a 45-degree bending method, and the other end of the tension steering plate 8 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com