Terminal sheath and terminal connector

A terminal and sheath technology, which is applied in the field of terminal sheaths and terminal connectors, can solve the problems of insufficient withstand voltage, large installation space, short circuit, etc., to improve the withstand voltage protection performance, avoid protruding, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

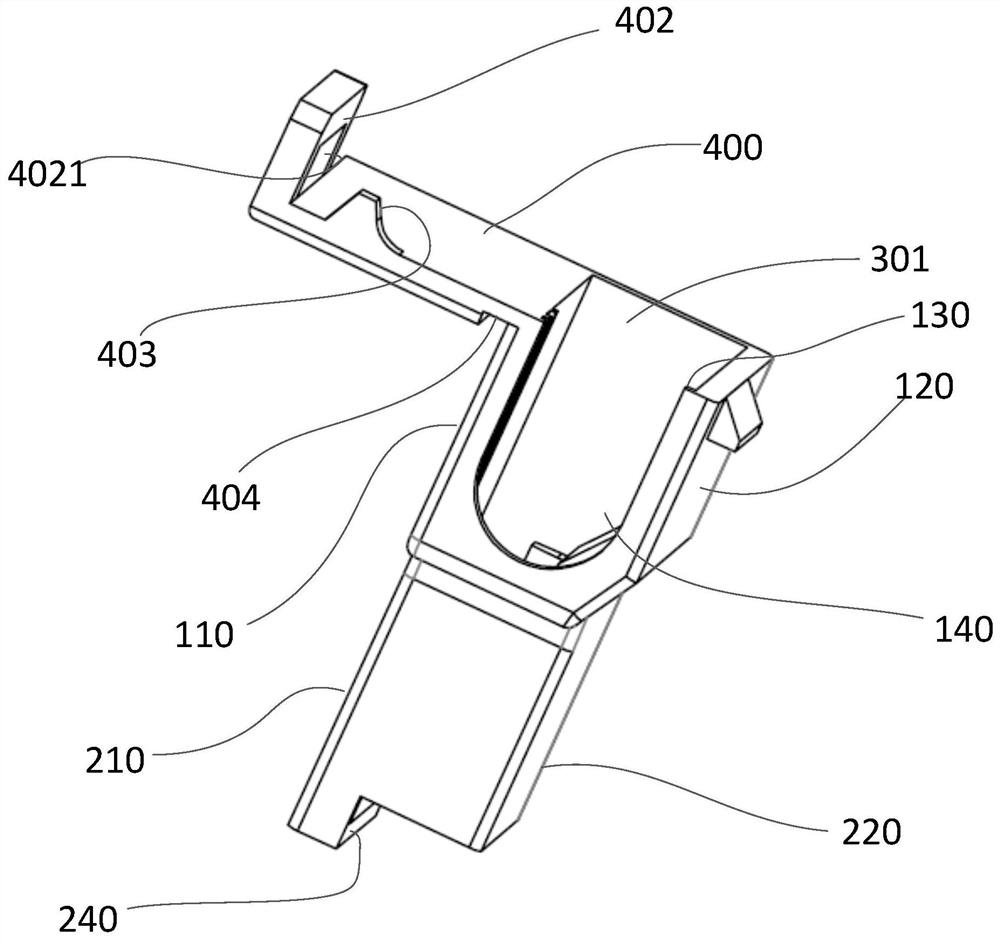

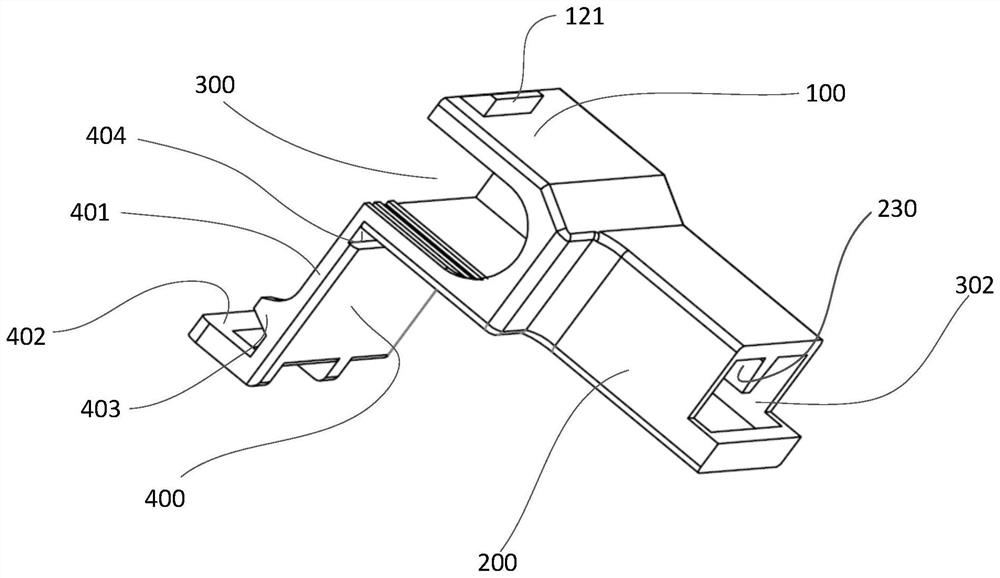

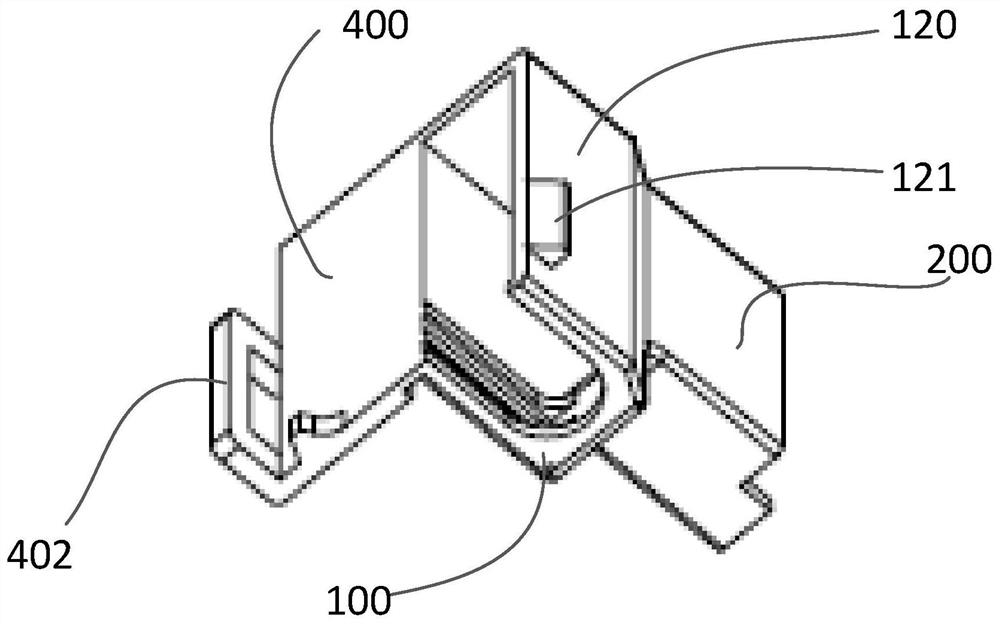

[0045] see Figure 1 to Figure 7, The present embodiment provides a terminal sheath 1. The present invention discloses a relay for providing insulation protection for terminals, a micro switch, a heating rod, a boat switch, and a terminal sheath for PCBA6.3 / 4.8 sockets. Specifically, the terminal sheath is suitable for the insulation protection of relay terminals for plug-in assembly. More specifically, the terminal sheath is suitable for but not limited to (American standard) 250 / 187 relay inserts, or 6.3, 4.8 and other (successful standard) relay inserts.

[0046] The terminal sheath 1 includes: a main body. Wherein, the main body has an inlet 301 and an inlet 302 facing away from each other. The main body has a through hole 300 communicating with the inlet 301 and the socket 302 . The through hole 300 extends lengthwise. The inlet 301 is used for inserting the terminal 2 into the through hole 300 of the main body to form a terminal connector. The pair of sockets 302 ar...

Embodiment 2

[0062] see Figure 8 to Figure 11 , an embodiment of the present application is a terminal sheath. Among them, such as Figure 7 As shown, the mating terminal has a flag-shaped structure. The mating terminal has a sheet body, a groove wall disposed on the sheet body and protruding from the sheet body, and a groove portion defined by the groove wall. The sheet body is a metal sheet body. The groove wall is formed by winding the side of the sheet. Of course, in other embodiments, the groove wall may also be a stamped protrusion on the sheet. A groove is formed between the groove walls on both sides of the sheet. The groove wall is formed on the sheet body, and one end of the sheet body is provided with a connecting end connected with the cable. The other end of the sheet is free and inserted into the terminal shield. The groove wall and the groove portion extend between the free end and the connection end. The end of the groove wall close to the connecting end is the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com