Testing and calculating method for measuring hole expansion rate

A calculation method and technology of hole expansion rate, applied in the direction of applying repetitive force/pulsation force to test material strength, measuring devices, instruments, etc., can solve the problems of limited hole expansion test standard engineering application, so as to save purchase cost and management Cost, enhanced application space, and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

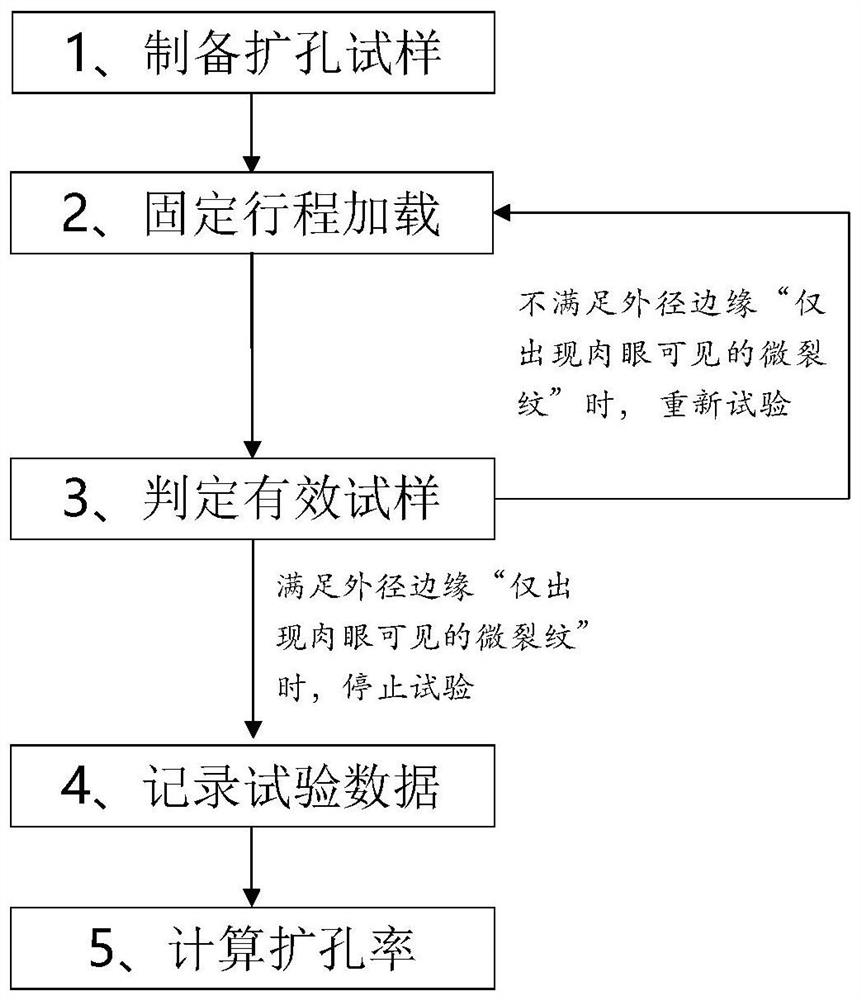

[0078] In this embodiment, the material DP780 / 2.1mm is taken as an example, and its flow chart is as follows figure 1 The new reaming test flowchart of shown embodiment one comprises the steps:

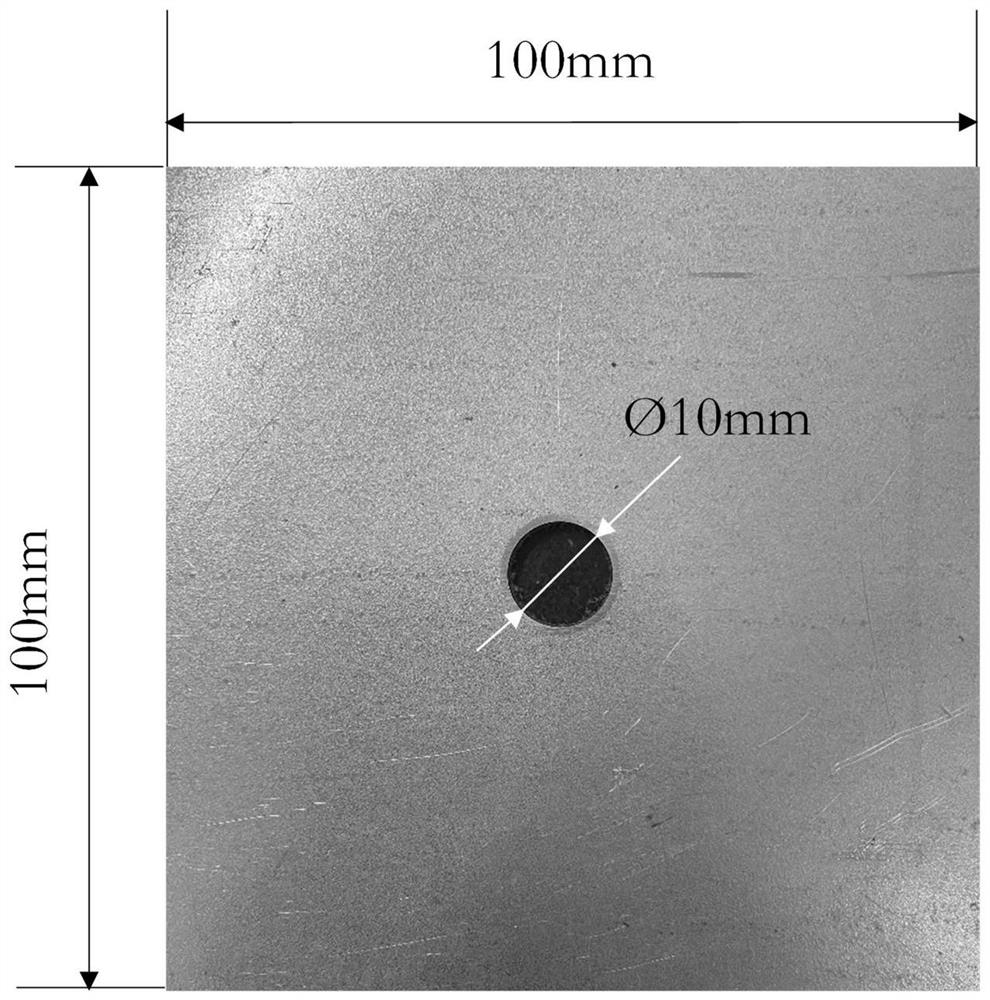

[0079] Step 1. Preparation of reaming samples: According to the sample size requirements and punching regulations stipulated in GB / T 24524 or ISO 16630 standards, prepare a number of samples with an initial diameter of D 0 Reaming specimens equal to 10mm, such as figure 2 Specimens after punching as shown;

[0080] Step 2, fixed-stroke loading: take 3 samples from the prepared reaming samples; place the reaming samples on the reaming testing machine with the burrs facing upwards, and keep the lower edge of the hole in line with the The conical punch is in contact, that is, the empty stroke d 0 equal to zero, then the set fixed loading stroke d fix Equal to effective loading stroke d eff . In this fixed stroke loading test, the effective loading stroke d eff It is equal to 6.87...

Embodiment 2

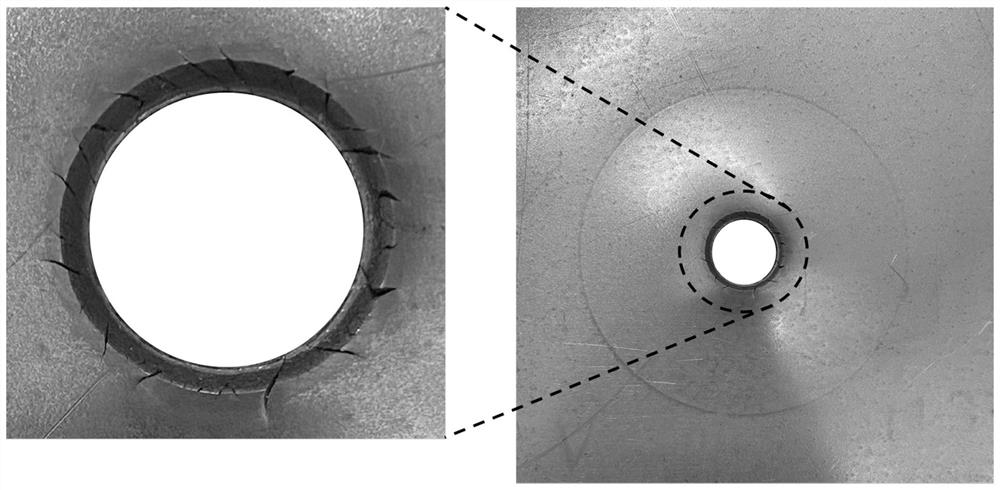

[0095] According to the test process and test method in Example 1, the sample burr is facing down, and the hole expansion test is carried out. When the effective loading stroke is equal to 6.3mm, there is one sample among the three samples, and the edge of the outer diameter of the hole is the most serious. The state of the crack is "only micro-cracks visible to the naked eye", such as Figure 9 Microcracks are visible to the naked eye on the edge of the outer diameter of the hole with the burr facing downward, and no microcracks visible to the naked eye are seen in the other two samples, which meet the test termination conditions, and this sample is judged to be an effective sample. Measure and record the outer diameter D of this effective sample after reaming out Equal to 12.45mm, then the hole expansion rate of material DP780 with burrs facing downward measured in this hole expansion test is 24.5%. If there are multiple effective samples, take the average value as the hole...

Embodiment 3

[0097] In this embodiment, the material DP780 / 2.1mm is taken as an example, and its flow chart is as follows figure 1 shown, including the following steps:

[0098] Step 1. Preparation of reaming samples: According to the sample size requirements and punching regulations stipulated in GB / T 24524 or ISO 16630 standards, prepare a number of samples with an initial diameter of D 0 Reaming specimens equal to 10mm, such as figure 2 shown;

[0099] Step 2, fixed-stroke loading: take 3 samples from the prepared reaming samples; place the reaming samples on the reaming testing machine with the burrs facing upwards, and keep the lower edge of the hole in line with the The conical punch is in contact, that is, the empty stroke d 0 equal to zero, then the set fixed loading stroke d fix Equal to effective loading stroke d eff . In this fixed stroke loading test, the effective loading stroke d eff It is equal to 6.878mm, and the same effective loading stroke is used to carry out th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com