Adaptive projection moire method for continuous surface

A projection moiré and self-adaptive technology, applied in the field of optical measurement, can solve the problems of poor measurement performance, low energy consumption and irregular distribution of moiré patterns in the whole field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

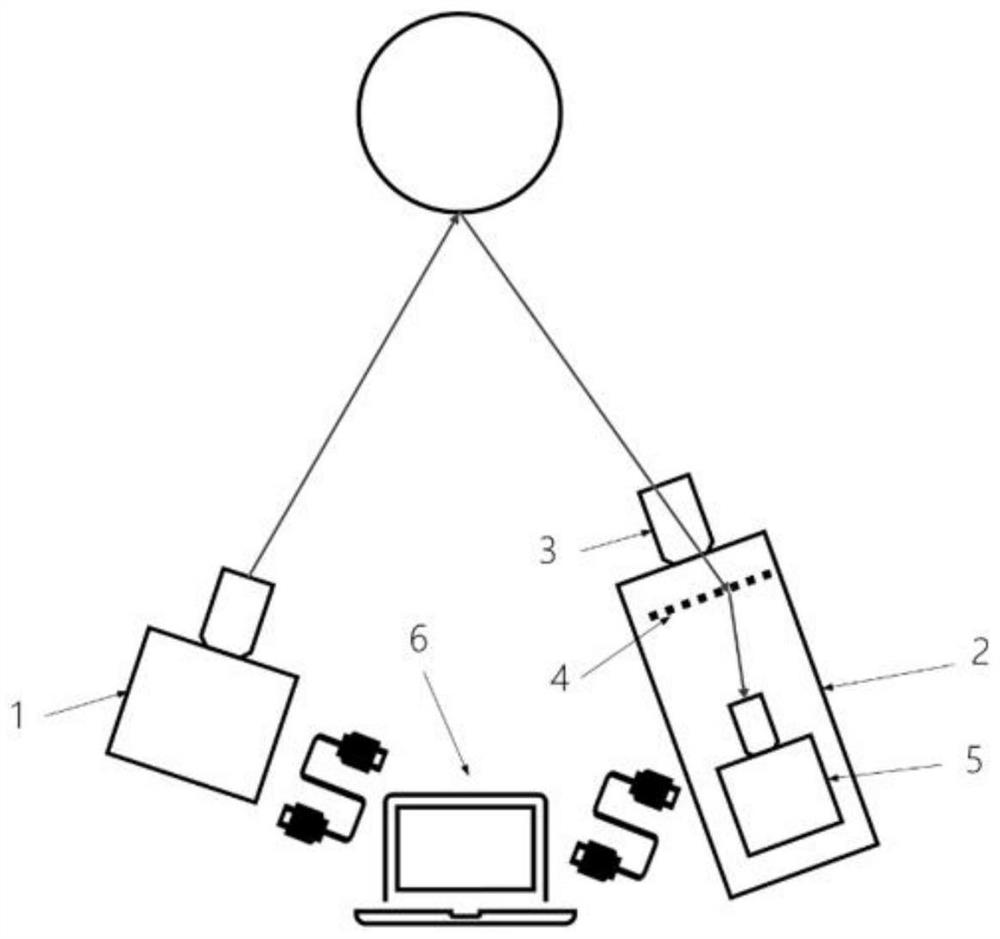

[0024] Such as figure 1 As shown, it is an adaptive projection moiré system for a continuous surface related to this embodiment, including: a projector 1 as a grid line projection system, a physical reference grating 4 arranged in a casing 2, a zoom lens 3, CCD camera 5 and the image processing control system 6 that is connected with projector 1 and CCD camera 5 respectively, wherein: image processing control system 6 outputs to projector 1 the raster line picture that needs projection and receives the picture that takes from CCD camera 5, Process and calculate the shape of the object by processing the moiré pictures captured by the camera.

[0025] In this embodiment, the zoom lens 3 adopts, but is not limited to, a zoom lens with a short focal length, which is used to receive the grating lines on the surface of the object and converge them on the reference grating. The zoom lens 3 is fixed on the housing 2 through a special bayonet.

[0026] The physical reference grating 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com