Constant-temperature bridge leakage-proof water stop strip

A technology for waterstops and bridges, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of long maintenance time and low equipment service life, and achieve the effects of short maintenance time, improved service life and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of constant temperature type bridge leak-proof water-proof strip, see Figure 1 to Figure 7 , the design includes the outer layer of the flexible water stop strip 1 and the inner layer of the diversion pipe 2 is installed in combination, and the end of the diversion pipe 2 is provided with an airflow guide element to achieve cooling, and the diversion pipe 2 is provided with multiple groups of cross rows Distributed scale-like dust shelters 3, a shaping mechanism 7 is provided in the diversion pipe 2, and the flexible water-stop strip 1 includes several water-stop unit blocks overlapped in the shape of tiles, and the water-stop unit blocks are provided with top bulges. Part 4, side positioning part 5 and bottom lifting part 6. In the working state, the inside of the flexible waterstop receives rainwater or other liquids leaked from the expansion joints, collects them in the internal diversion pipe, and finally discharges them through the outlet. During this perio...

Embodiment 2

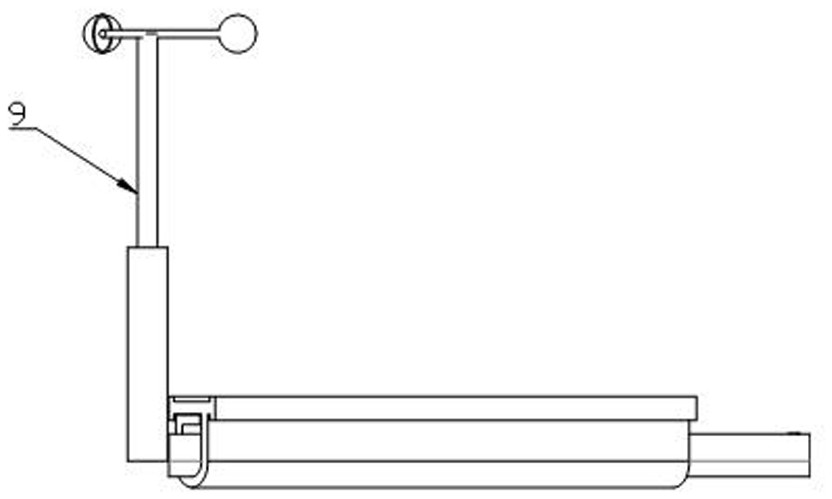

[0047] The principle of this embodiment is the same as that of Embodiment 1, the specific difference is that the airflow guide element includes the air rod 9 installed on the edge of the water stop strip and corresponding to the side of the bridge, and the bottom of the air rod 9 is linked with the fan blade to form a vacuum air layer, and the guide The other end of the flow pipe 2 communicates with the bridge sewer pipe. It is convenient for ventilation at the bottom, realizes local cooling, especially in the case of local high temperature of the bridge, and effectively prolongs the service life of the equipment. In this design, the wind mast is small in size and is located on the edge of the bridge, so it will not hinder the sight on both sides of the road.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com