Functional spandex fiber preparation method

A spandex fiber and functional technology, applied in the field of preparation of functional spandex fiber, can solve problems such as the limitation of application scope, and achieve the effects of wide application field, good antibacterial property and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

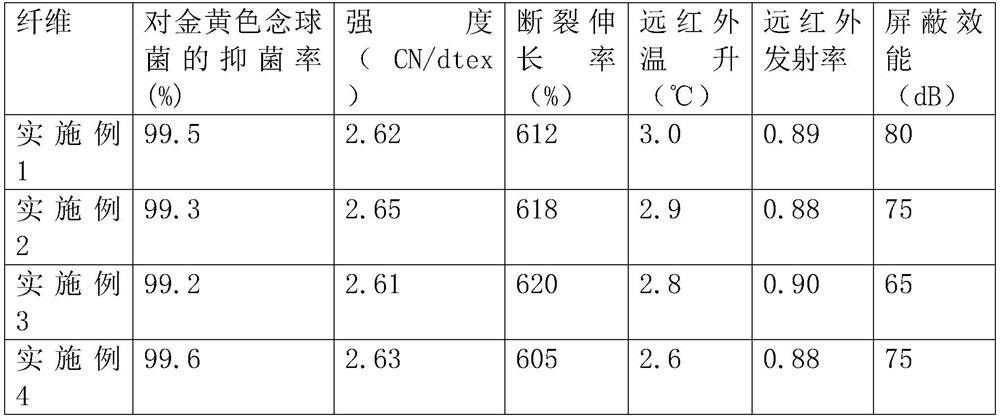

Examples

Embodiment 1

[0026] The preparation method of functional spandex fiber, the preparation method comprises the following steps:

[0027] 1) Preparation of prepolymer: N,N-dimethylacetamide, A part graphene, polyether diol, and then add diisocyanate according to the ratio of NCO / OH=1.70~1.90; prepolymerization reaction temperature The temperature is controlled at 70-80°C, and the reaction time is 3.0-4 hours. During the reaction, nitrogen gas is introduced for protection to obtain a prepolymer solution with a solid content of 38%-40%. The number-average molecular weight of the polyether glycol is 2000 ~2500, the molecular weight distribution is 1.4~1.5.

[0028] 2) mixing the graphene, zinc oxide nanoparticles and / or titanium dioxide nanoparticles, mixed amines, and auxiliary materials in part B in N, N-dimethylacetamide to obtain a mixed amine solution;

[0029] The added amount of zinc oxide nanoparticles and / or titanium dioxide nanoparticles accounts for 2% of the functional spandex fiber...

Embodiment 2

[0039] The preparation method of functional spandex fiber, the preparation method comprises the following steps:

[0040] 1) Preparation of prepolymer: N,N-dimethylacetamide, A part of nano-carbon fiber material, polyether diol, and then add diisocyanate according to the ratio of NCO / OH=1.70~1.90; prepolymerization reaction The temperature is controlled at 70-80°C, the reaction time is 3.0-4 hours, and nitrogen gas is passed into the reaction process for protection to obtain a prepolymer solution with a solid content of 38%-40%; the number average molecular weight of the polyether glycol 2000-2500, molecular weight distribution 1.4-1.5

[0041] 2) Mix the carbon nanofiber material, zinc oxide nanoparticles and / or titanium dioxide nanoparticles, mixed amine, and auxiliary materials in N, N-dimethylacetamide to obtain a mixed amine solution;

[0042] The mass ratio of the carbon nanofiber material in the A part to the carbon nanofiber material in the B part is 3:7;

[0043] Th...

Embodiment 3

[0051] The difference with Example 1 is only: step 1) and step 2) add the mixture of graphene and carbon nanofiber material in any proportion, the addition of graphene and carbon nanofiber material accounts for the adjustment of functional spandex fiber quality to be 8% .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com