Brake anti-seizure lubricant as well as preparation method and application thereof

A technology of lubricants and raw materials, applied in the field of brake anti-seize lubricant and its preparation, can solve the problems of not improving safety performance, reducing lubricant effect, braking slippage, etc., and improving scrub resistance and good lubricity. , the effect of improving anti-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

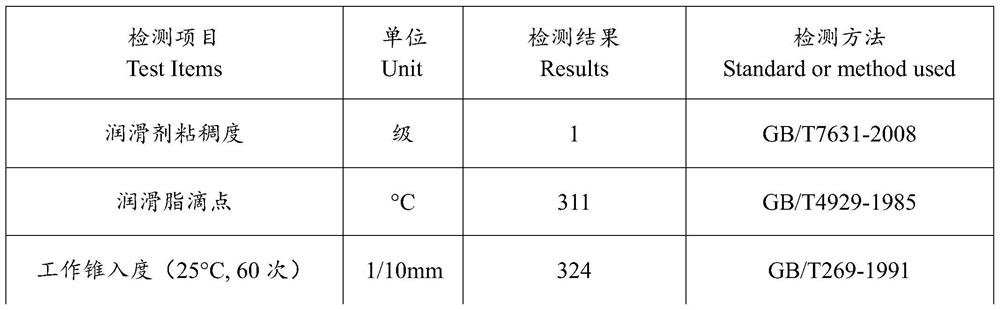

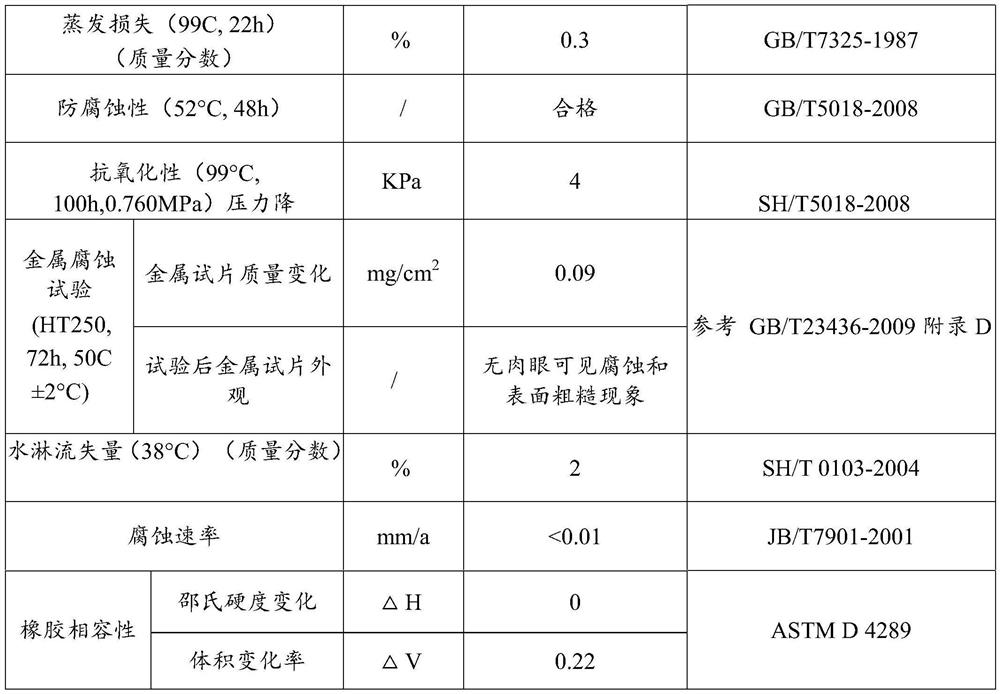

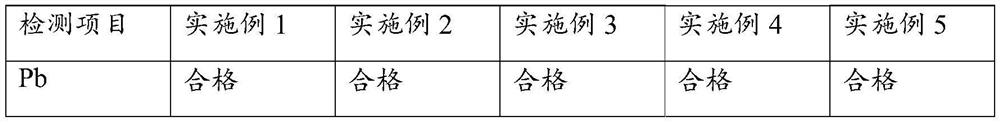

Examples

Embodiment 1

[0052] Weighing less mass percentage of raw materials:

[0053] Molybdenum dialkyl dithiophosphate salts of 2%;

[0054] Dithiocarbamate 3% molybdenum;

[0055] Dodecenylsuccinic acid 0.1%;

[0056] 5% aluminum powder of silver;

[0057] Dialkyl diphenylamine 0.1%;

[0058] Dimethylsiloxane margin.

[0059] The above polydimethylsiloxane said dialkyl molybdenum dithiophosphate, molybdenum dithiocarbamate, dodecenylsuccinic acid, silver and aluminum dialkyl aniline was added to the kettle harmonic, It was stirred at 80rpm to give a uniform speed braking conditions bite-preventing lubricant.

Embodiment 2

[0061] Weighing less mass percentage of raw materials:

[0062] Dialkyl dithiophosphate 4% molybdenum;

[0063] Dithiocarbamate 8% molybdenum;

[0064] Dodienyl butcodic acid 0.5%;

[0065] Silver aluminum powder 15%;

[0066] 0.5% of dialkyl diphenylamine;

[0067] 5% of nano silica;

[0068] Dimethylsiloxane.

[0069] The above dimethylsiloxane, nanosily silica is added to the tonifying kettle, and the mixture is mixed under 80 rpm radiosity conditions;

[0070] The above dialkyl dithiophosphate salt, dithiocarbamate, dodecaric acid, silver-aluminum powder and dialkyl diphthiline were added to the mixture to obtain a brake bite lubricant.

Embodiment 3

[0072] Weighing the following mass percentage of raw materials:

[0073] Dialkyl dithiophosphate molybdenum salt 4%;

[0074] Sulfurminamine molybdenum is 8%;

[0075] Dodienyl butcodic acid 0.5%;

[0076] Silver aluminum powder 15%;

[0077] 0.5% of dialkyl diphenylamine;

[0078] 10% of nano silica;

[0079] Dimethylsiloxane.

[0080] The above dimethylsiloxane, nanosily silica is added to the tonifying kettle, and the mixture is mixed under 80 rpm radiosity conditions;

[0081] The above dialkyl dithiophosphate salt, dithiocarbamate, dodecaric acid, silver-aluminum powder and dialkyl diphthiline were added to the mixture to obtain a brake bite lubricant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| drop melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com