A kind of preparation method of non-clinker-free burning-free environmental protection bricks mixed with sludge incineration ash

A sludge incineration, clinker-free technology, applied in cement production, sustainable waste treatment, solid waste management, etc., can solve problems such as the ineffective utilization of sludge incineration ash, the small amount of cement produced, and the impact on product performance. , to achieve the effect of good promotion and application prospects, fast turnover of brick-making process, and rapid increase in strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A method for preparing a clinker-free burning-free environment-friendly brick by adding sludge incineration ash according to the present invention is prepared by adopting the following raw materials by weight:

[0036] Activated sludge incineration ash: 100 parts;

[0037] Sand: 80 to 120 parts;

[0038] Crushed stone: 50 to 80 parts;

[0039] Saturated lime water: 95-140 parts;

[0040] The preparation method of non-clinker-free burning-free environmental protection bricks mixed with sludge incineration ash comprises the following steps:

[0041] (1) material mixing: the above-mentioned raw materials are weighed according to the formula and poured into a stirring pot for full mixing to obtain a uniform mixture;

[0042] (2) Compression molding: add the mixture obtained in step (1) into a mold, complete compression molding under a pressure of 3 to 7 MPa, and then stand for 8 to 12 hours under standard curing conditions after demoulding;

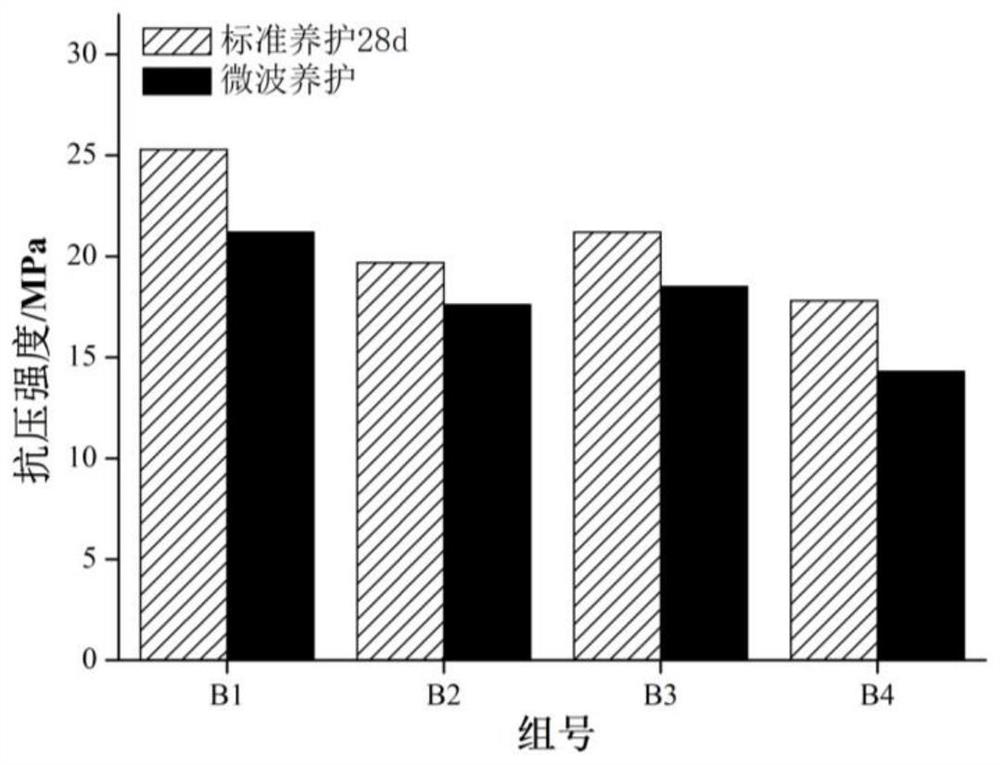

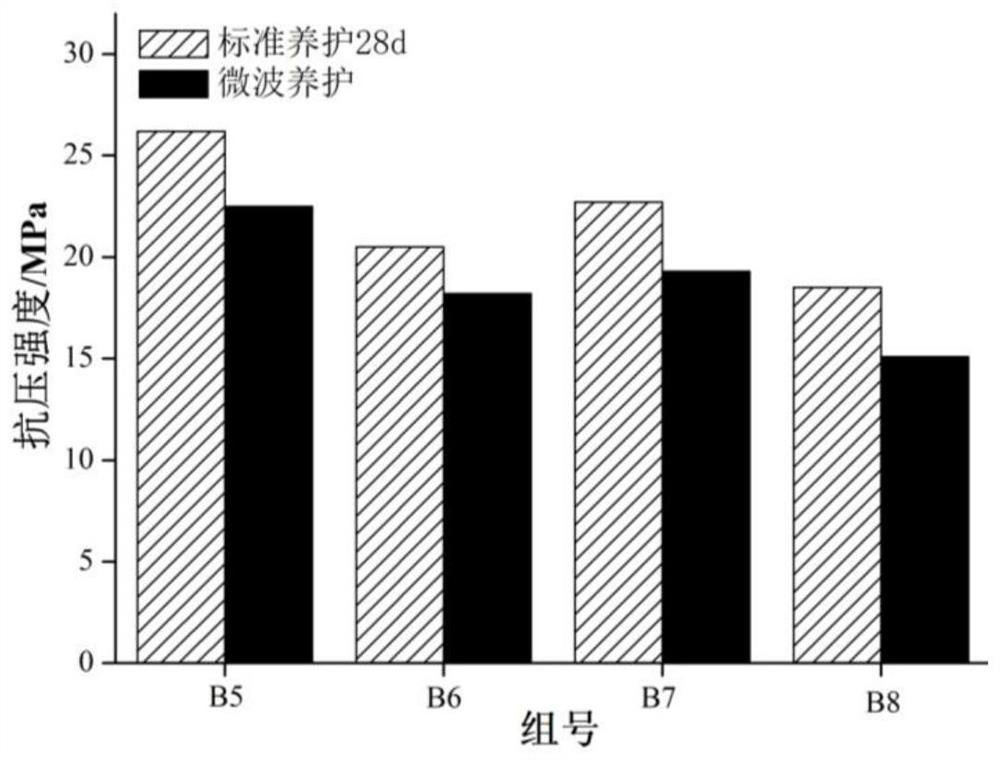

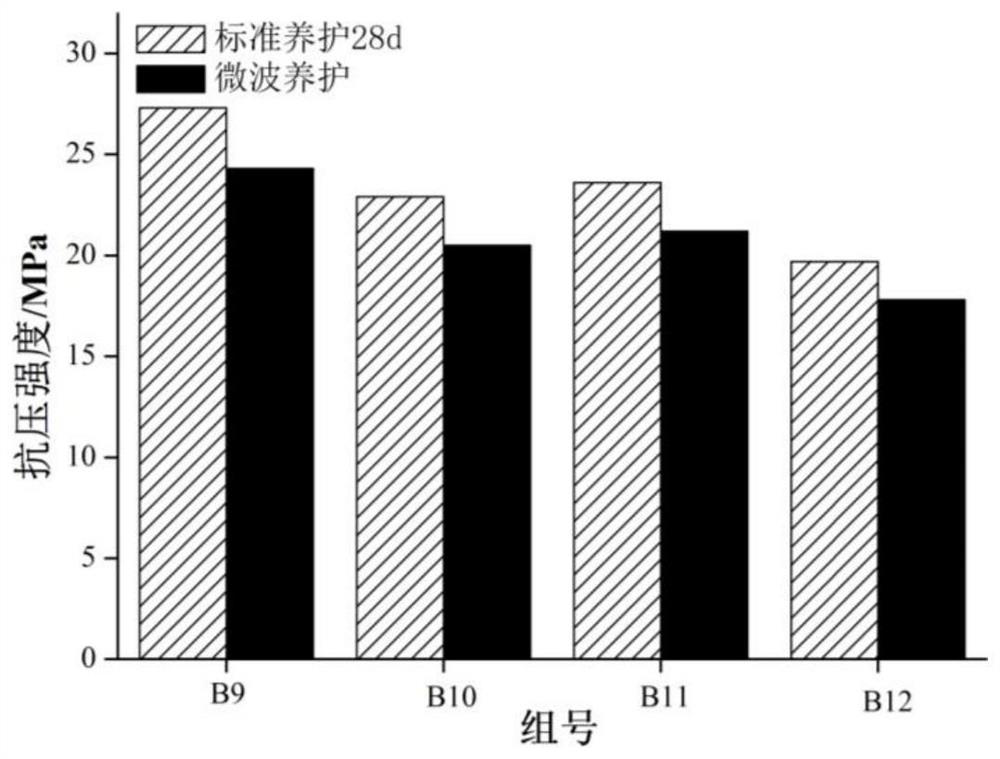

[0043] (3) Microwave curing...

Embodiment 1

[0066] A non-clinker-free burning environment-friendly brick mixed with sludge incineration ash is prepared by adopting the following process:

[0067] (1) 100 parts of activated sludge incineration ash (S1), 80 parts of natural sand with a fineness modulus of 2.5, 50 parts of natural graded crushed stone with a particle size of 5 to 10 mm and 95 parts of saturated lime water were added to the stirring pot and mixed Homogeneous, saturated lime water is saturated Ca(OH) 2 solution;

[0068] (2) adding the mixture obtained in step (1) into a mold, molding under a pressure of 3 MPa, and standing for curing for 8 hours at a temperature of 20±2° C. and a relative humidity greater than 95% after demoulding;

[0069] (3) placing the sample that has been left standing for curing in step (2) in a microwave environment, the microwave frequency is 2400-2500MHz, and the microwave curing system is: 100W curing for 5min, stopping for 3min, and reciprocating like this for 3 times; 2) 150W c...

Embodiment 2

[0072] A non-clinker-free burning environment-friendly brick mixed with sludge incineration ash is prepared by adopting the following process:

[0073] (1) Add 100 parts of activated sludge incineration ash (S1), 96 parts of machine-made sand with a fineness modulus of 2.7, 67 parts of natural graded crushed stone with a particle size of 5-10 mm and 122 parts of saturated lime water into a stirring pot and mix Homogeneous, saturated lime water is saturated Ca(OH) 2 solution;

[0074] (2) adding the mixture obtained in step (1) into a mold, molding under a pressure of 4.5 MPa, and curing for 9 hours at a temperature of 20±2° C. and a relative humidity greater than 95% after demoulding;

[0075] (3) placing the sample that has been left standing for curing in step (2) in a microwave environment, the microwave frequency is 2400-2500MHz, and the microwave curing system is: 100W curing for 5min, stopping for 3min, and reciprocating like this for 3 times; 2) 150W curing for 3min, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com