Underwater granulator for low-melting-point hot melt adhesives

An underwater pelletizer, hot melt adhesive technology, applied in mechanical equipment, metal processing, springs/shock absorbers, etc., can solve the problems of waste of material resources, inability to disassemble and replace, avoid waste, ensure normal service life, Noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

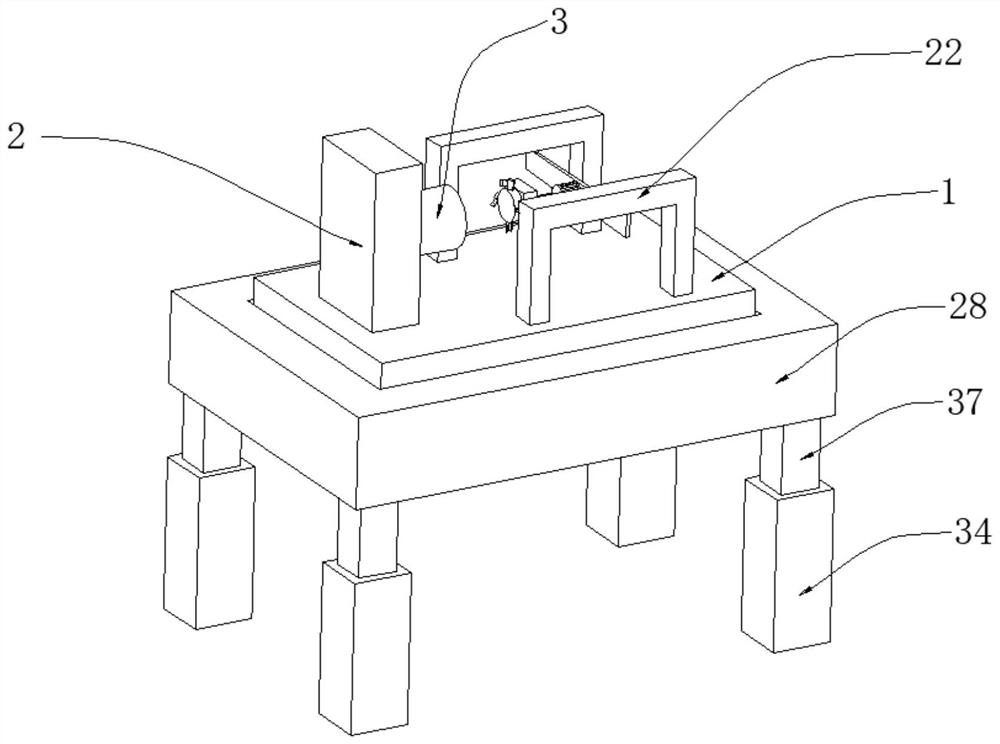

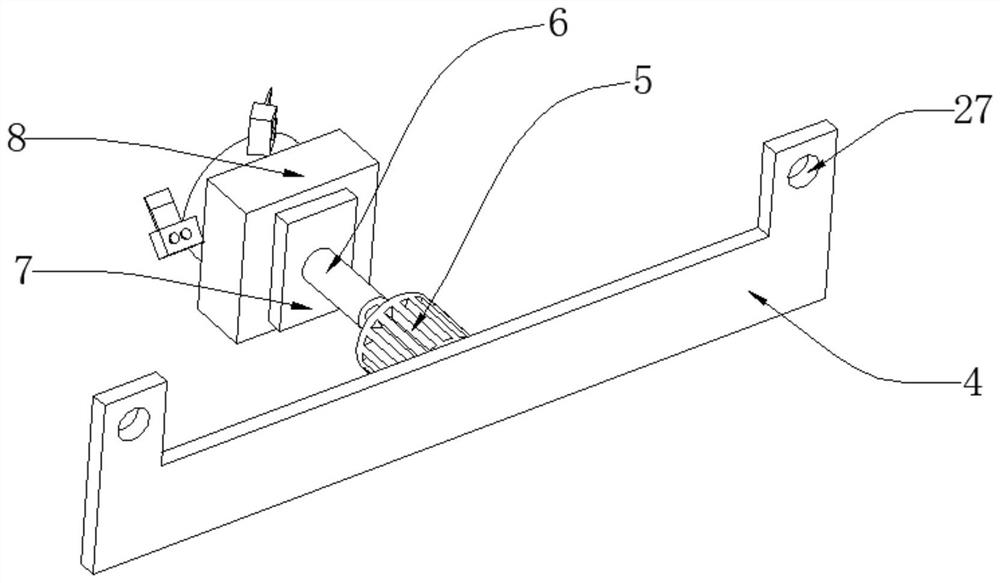

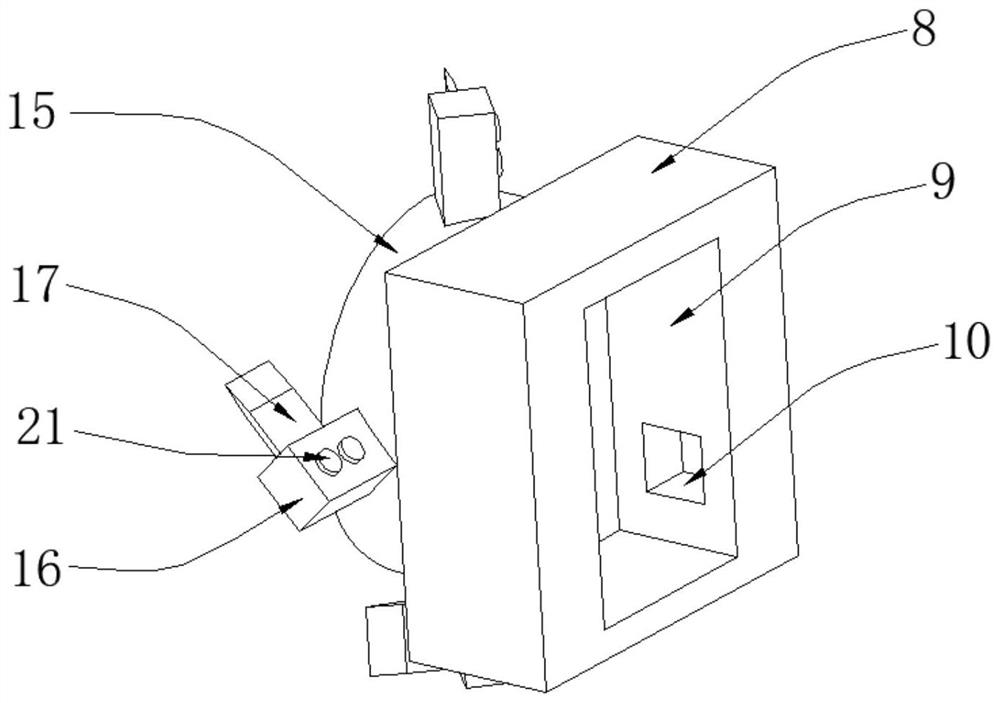

[0028] like Figure 1-6 As shown, the present invention provides an underwater pelletizer for low-melting hot melt adhesives, including a workbench 1, an extrusion device 2 is fixedly installed on one side of the top surface of the workbench 1, and a pelletizer is fixed on one side of the extrusion device 2. Room 3, the other side of the top surface of the workbench 1 is provided with a U-shaped plate 4 that moves along the horizontal direction, and both sides of the top surface of the workbench 1 are fixedly installed with a gantry frame 22, and the bottom surface of the gantry frame 22 is provided with a movable groove 23 for placing The third motor 24 and the second screw mandrel 25, the third motor 24 is fixedly installed on one side of the movable groove 23 inner walls, and provides power for the rotation of the second screw mandrel 25, and the output shaft of the third motor 24 is fixedly installed the second screw mandrel 25, so that When the third motor 24 starts, it c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com