Cylindrical insulator inner hole groove rolling machine

A technology of insulators and roller grooves, applied in pressing rollers, ceramic molding machines, auxiliary molding equipment, etc., can solve the problems of increased inner wall friction, high production cost, and reduced electrical performance of products, and achieves improved high-voltage resistance performance. Overall roll groove effect, convenient position adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions in the embodiments of the present invention will be clearly and completely described below. The embodiments of the present invention and all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

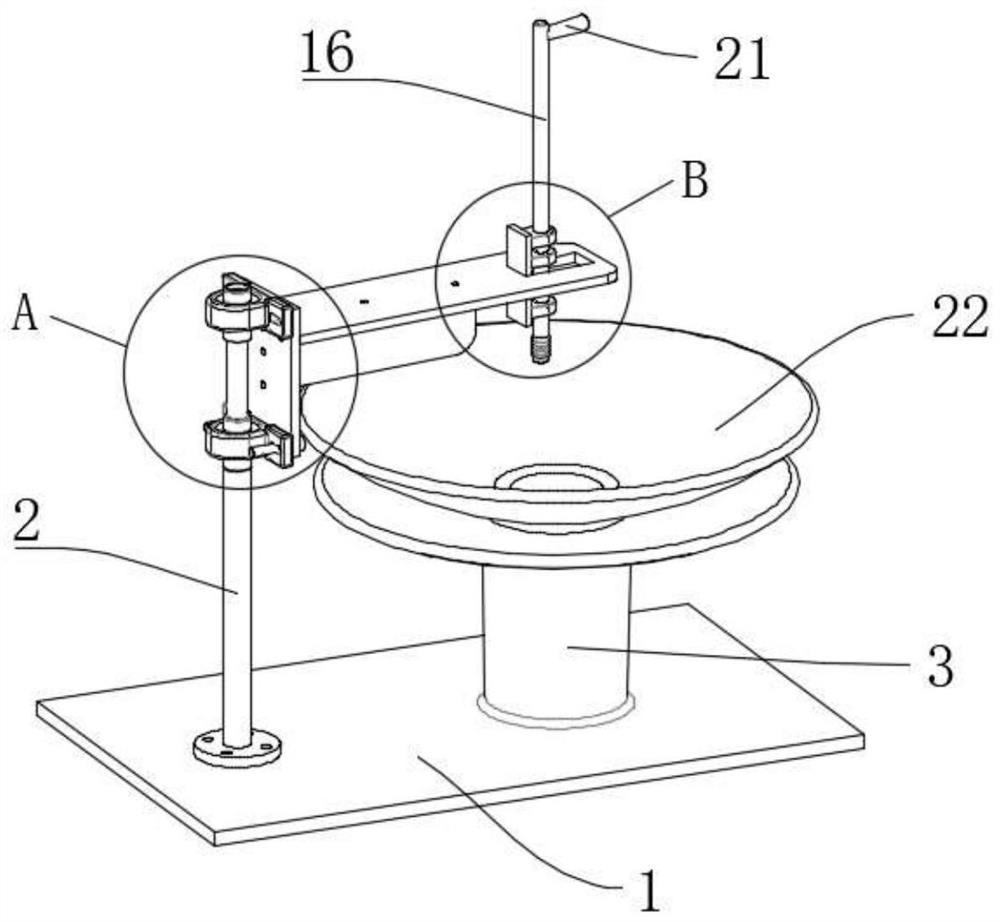

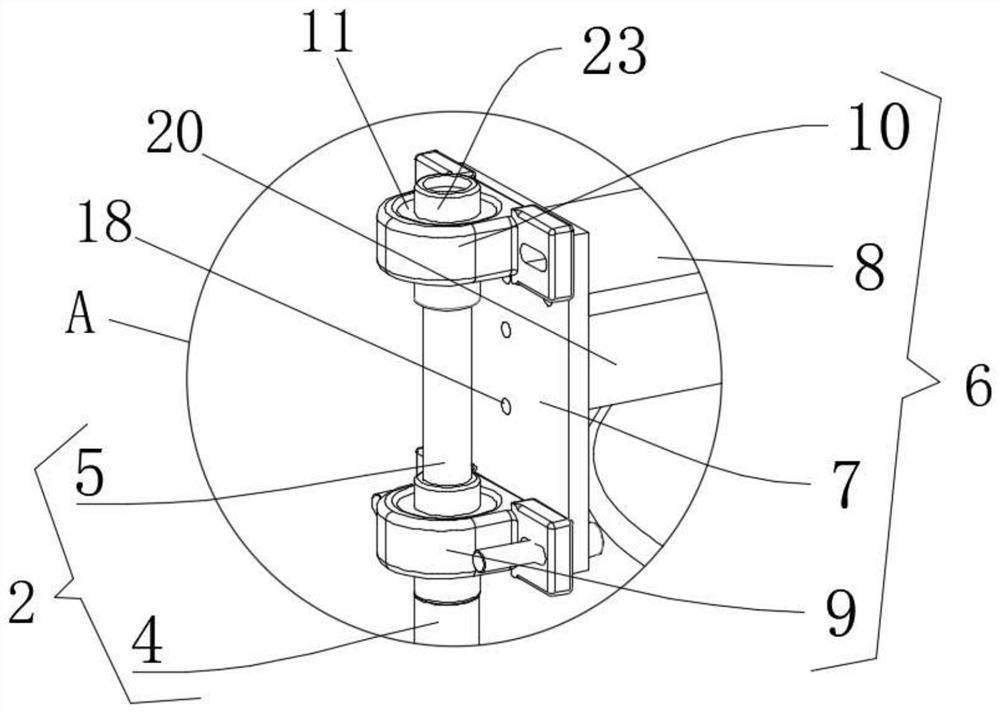

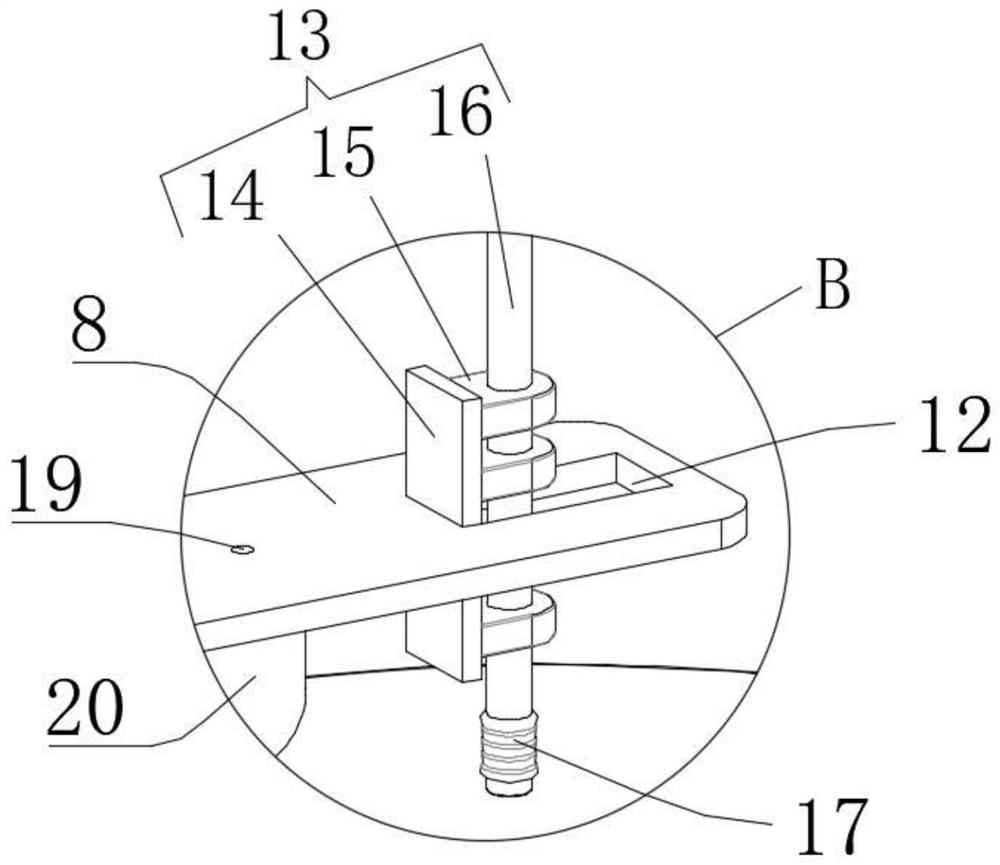

[0020] see Figure 1-4 , the present invention provides a technical solution: a cylindrical insulator inner hole roller groove machine, including a base 1, a vertical rod 2, a porcelain part placement seat 3, a rotating support 6 and a roller groove assembly 13, the base 1 is a rectangular platform, and the vertical The rod 2 is composed of a mounting tube 4 and a rotating rod 5. The lower end of the mounting tube 4 is fixedly welded on the base 1. The rotating rod 5 is installed in the inner cavity of the mounting tube 4. The rotating support 6 is composed of a mounting plate 7, The crossbeam plate 8, the lower bearing seat 9 and the upper bearing sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com