Positive lithium supplement additive, positive pole piece, preparation method of positive pole piece and lithium ion battery

A positive electrode and additive technology, applied in secondary batteries, secondary battery repair/maintenance, circuits, etc., can solve problems such as potential safety hazards and adverse effects on the overall performance of the battery, and improve high voltage resistance and overcharge. capacity and cycle performance, and the effect of improving the first charge-discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038]According to a third aspect of the present invention, the present invention provides a method for preparing a positive electrode sheet, the method comprising: firstly dispersing a binder and a conductive agent in a solvent evenly, then adding a positive electrode active material to disperse evenly, and finally adding a positive electrode supplementary The lithium additive is uniformly dispersed, and then the positive electrode current collector is subjected to slot die extrusion coating, drying the polar piece in an oven (temperature is 100-110° C.), cold roll rolling, and punching to obtain the positive electrode piece.

[0039] According to the fifth aspect of the present invention, the present invention provides a lithium ion battery, the lithium ion battery includes a positive electrode piece, a negative electrode piece, a non-aqueous electrolyte, a separator and a packaging film; wherein, the positive electrode piece is the The positive electrode sheet according to t...

Embodiment 1

[0043] (1) First mix Super P (2wt%) and PVDF (3wt%) in solvent NMP (nitrogen methyl pyrrolidone), then add LiNi 5 Co 2 Mn 3 O 2 (90wt%) mixed uniformly, finally added lithiated hydroxy-p-toluene (5wt%) and mixed uniformly, the positive electrode sheet was obtained by coating, baking, rolling and punching on aluminum foil;

[0044] (2) First dissolve carboxymethyl cellulose (CMC) (1.5wt%) in deionized water (solid content 1.5%), then add artificial graphite (85wt%), silicon oxide to the 50% CMC solution in turn (10wt%) and Super P (1wt%) were dispersed evenly, then the remaining CMC solution and SBR (2.5wt%) were added to disperse evenly, and the negative electrode sheet was obtained by coating, baking, rolling and punching on the copper foil;

[0045] (3) After assembling the positive electrode sheet, the negative electrode sheet and the separator, inject a non-aqueous electrolyte to obtain a lithium ion battery.

Embodiment 2

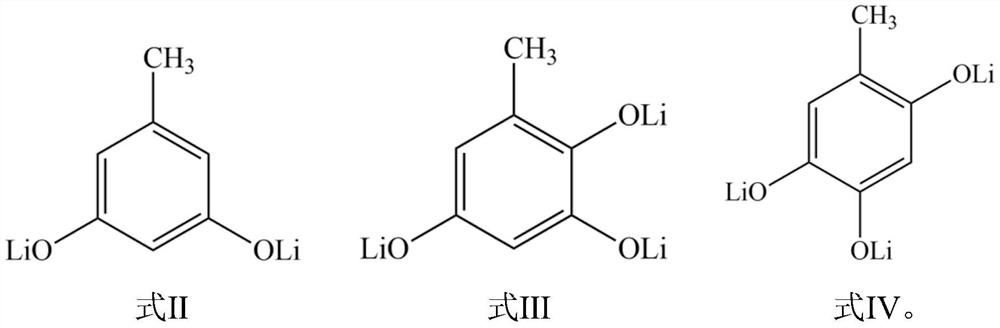

[0047] (1) First mix Super P (2wt%) and PVDF (3wt%) in solvent NMP (nitrogen methyl pyrrolidone), then add LiNi 5 Co 2 Mn 3 O 2 (90wt%) mixed uniformly, finally added lithiated 3,5-dihydroxymethylbenzene (5wt%) and mixed uniformly, the positive electrode sheet was obtained by coating, baking, rolling and punching on aluminum foil;

[0048] (2) First dissolve CMC (1.5wt%) in deionized water (solid content 1.5%), then add artificial graphite (85wt%), silicon oxide (10wt%), Super P to the 50% CMC solution in turn (1wt%) is uniformly dispersed, then the remaining CMC solution and SBR (2.5wt%) are added for uniform dispersion, and a negative electrode sheet is obtained by coating, baking, rolling and punching on the copper foil;

[0049] (3) After assembling the positive electrode sheet, the negative electrode sheet and the separator, inject a non-aqueous electrolyte to obtain a lithium ion battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com