Entrained flow gasifier device with four forward and reverse rotating burners and gasification method

A technology of rotating air flow and gasification furnace, which is applied in gasification process, granular/powdered fuel gasification, and production of combustible gas. and other problems, to achieve the effect of low fly ash combustible content and high carbon conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

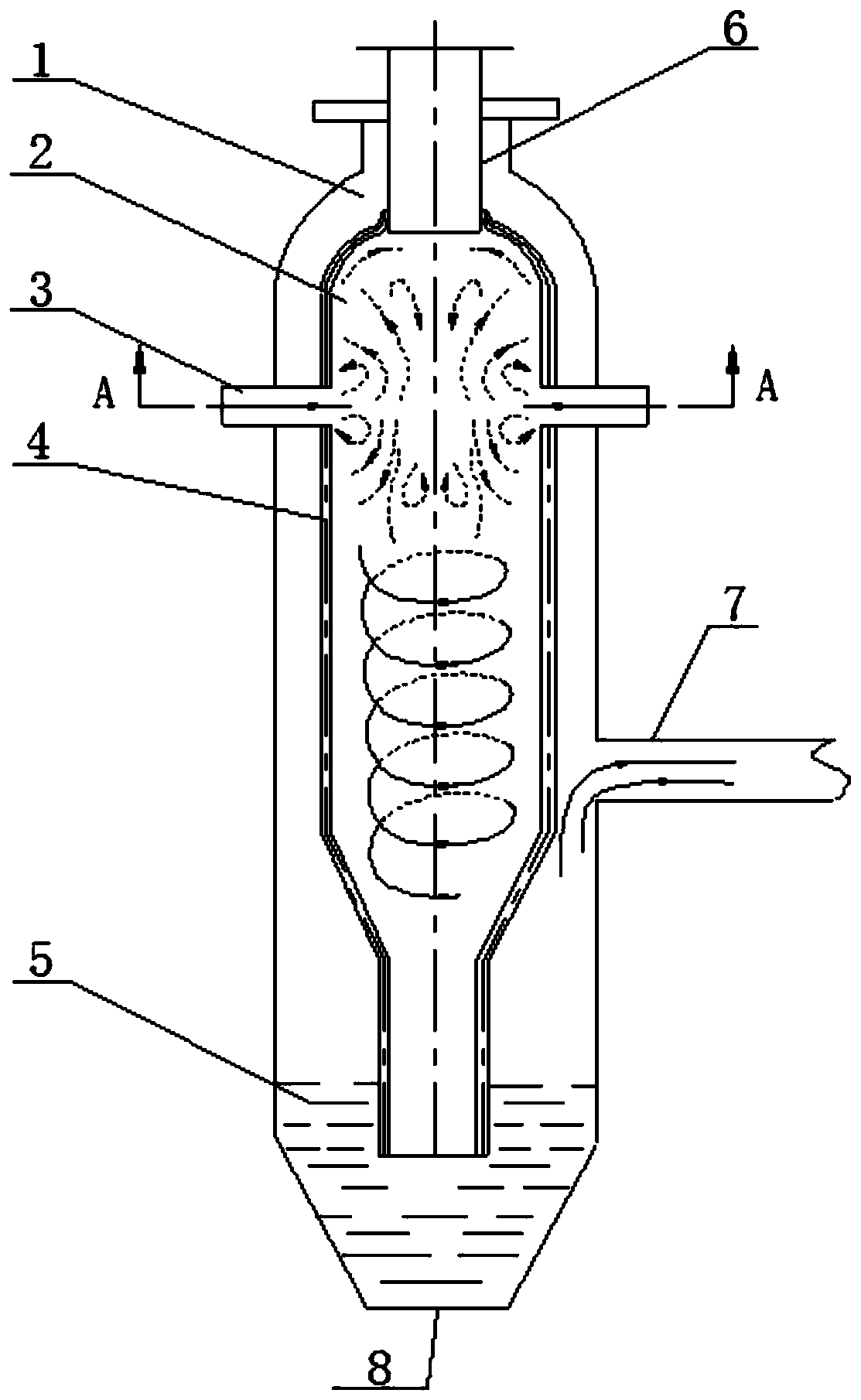

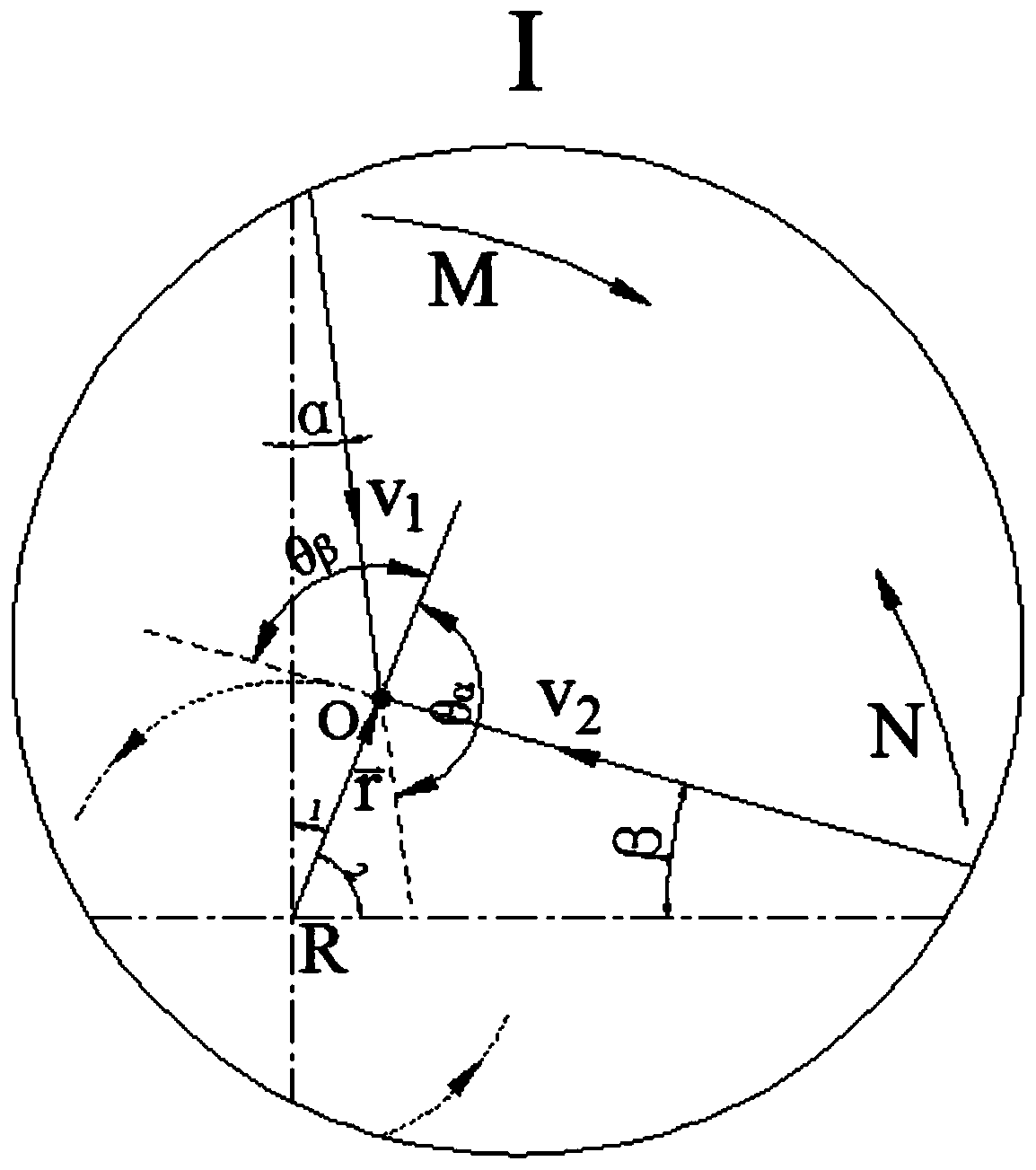

[0036] combine figure 1 , figure 2 and image 3 Describe the embodiment of the present invention. In this embodiment, the entrained-bed gasification furnace device with four burners rotating forward and backward includes a gasification furnace body 1, a burner, a water wall 4, an ignition burner 6, a slag pool 5 and a syngas channel 7. The water-cooled wall 4 is installed in the gasification furnace body 1. The water-cooled wall 4 is composed of a plurality of vertical circular tubes arranged. The water-cooled wall 4 forms a static inner cavity which is the gasification furnace 2. The igniti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com